Method used for increasing stability of water phase quantum dot

A quantum dot and stability technology, applied in the field of lighting, can solve the problems of long preparation time, poor luminescence performance, poor stability, etc., and achieve the effects of increasing the number of light excitations, improving luminescence performance, and preventing direct action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Take 2 mg of red CdTe quantum dots prepared in the aqueous phase system, mix with 2 g of 1-aminopropyl-3-methylimidazolium bromide salt ionic liquid, stir and react for 30min-12h, and bond the surface of quantum dots through amino groups, Quantum dots modified by ionic liquids are realized by exchanging sulfhydryl ligands on the surface of quantum dots with a large number of ionic liquids.

[0028] After the ionic liquid exchange, the quantum dot surface bond and the ionic liquid protective layer with a thickness of 10-20nm, the distance between the quantum dots>10nm, can effectively reduce the fluorescence resonance energy transfer (FRET) between the quantum dots, and reduce the distance between the quantum dots. reunion between.

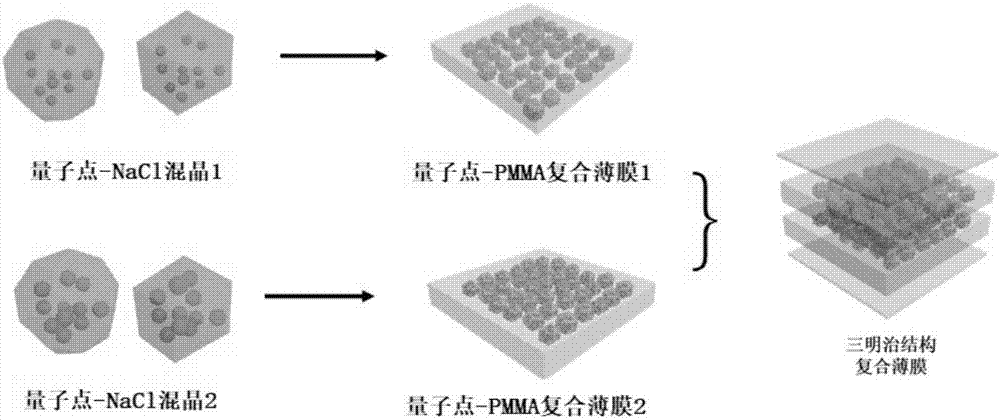

[0029] (2) The water-soluble quantum dot itself is a colloid dispersed in an aqueous solution, and its existing form is liquid. LED encapsulation devices require a solid powder or film light conversion layer, which cannot directly use q...

Embodiment 2

[0034] Take 10 mg of green CdSe quantum dots prepared in the aqueous phase system, mix them with 1 g of 1-carboxyethyl-3-methylimidazolium bromide salt ionic liquid, stir and react for 30min-12h, and form ligands through a large number of carboxyl groups and sulfhydryl groups on the surface of quantum dots exchanged to obtain modified quantum dots. The modified quantum dots are mixed with potassium bromide saturated solution to obtain quantum dot-potassium bromide mixed crystals. refer to Figure 4 The schematic diagram of the preparation process of the quantum dot-polymer microsphere shown, the quantum dot-potassium bromide mixed crystal is mixed with the polymer (such as PMMA, PS, etc.) solution, and realizes micron, submicron (100nm -10 μm) quantum dot-polymer microspheres, the spherical quantum dot-polymer composite microspheres can be directly used for On-Chip packaging of LEDs.

Embodiment 3

[0036] Take 10 mg of CdS quantum dots prepared in the aqueous phase system, mix them with 0.1 g of 1-carboxyethyl-3-methylimidazolium chloride salt ionic liquid, stir and react for 30min-12h, and form ligands through a large number of carboxyl groups and sulfhydryl groups on the surface of quantum dots exchanged to obtain modified quantum dots. The modified quantum dots are mixed with a sodium tetraborate saturated solution to obtain quantum dot-sodium tetraborate mixed crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com