N-doped porous carbon/MoS2 sodium ion battery negative electrode material and preparation method thereof

A technology for nitrogen-doped porous carbon and sodium-ion batteries, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of MoS2 poor conductivity and unsatisfactory electrochemical performance, and achieve good cycle stability, Good ion transport ability and the effect of enriching the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

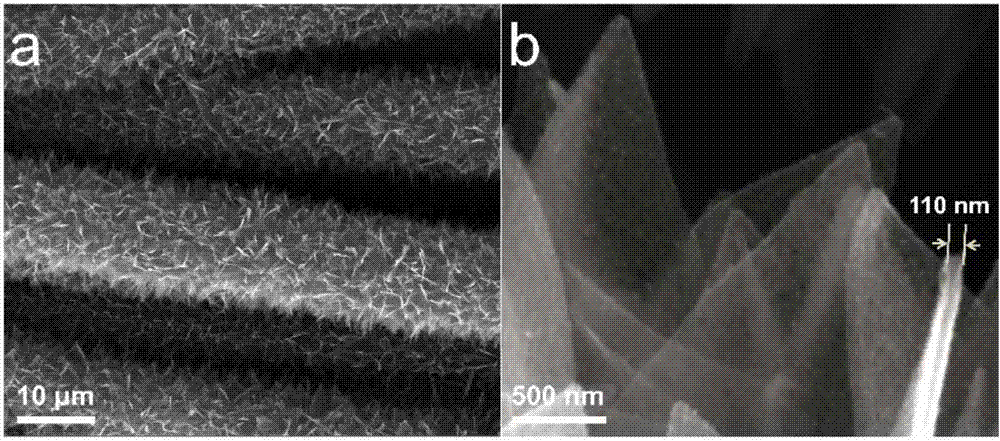

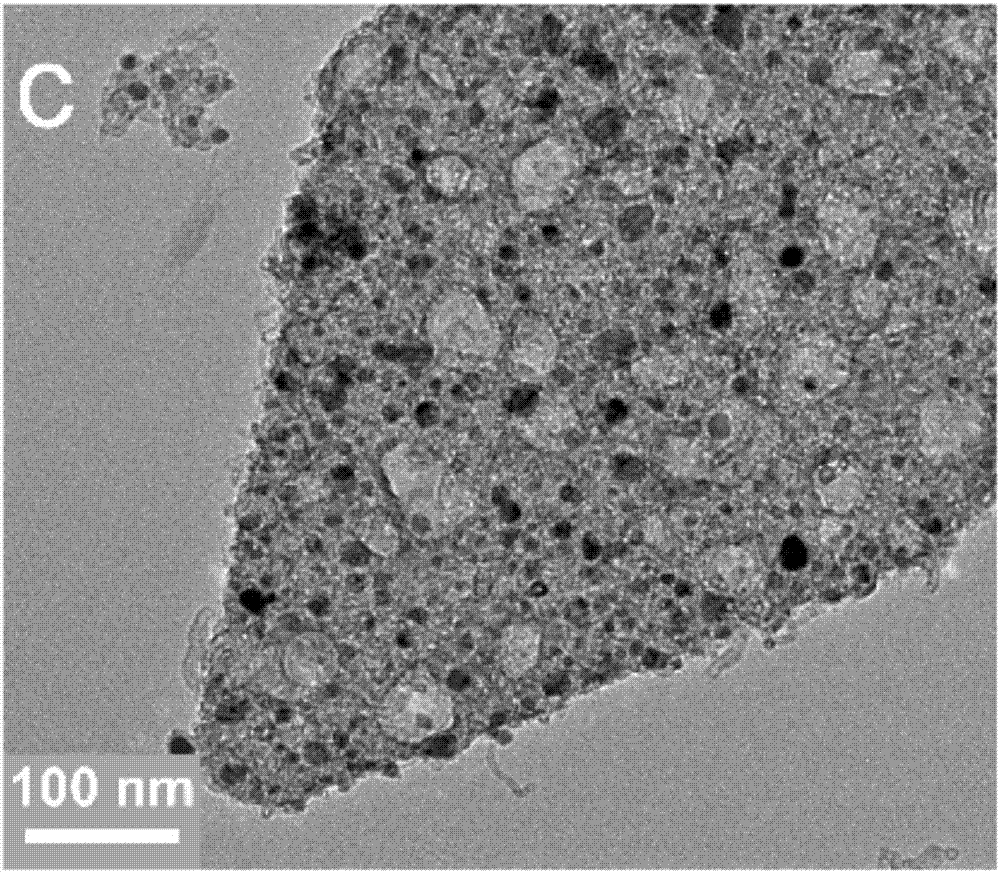

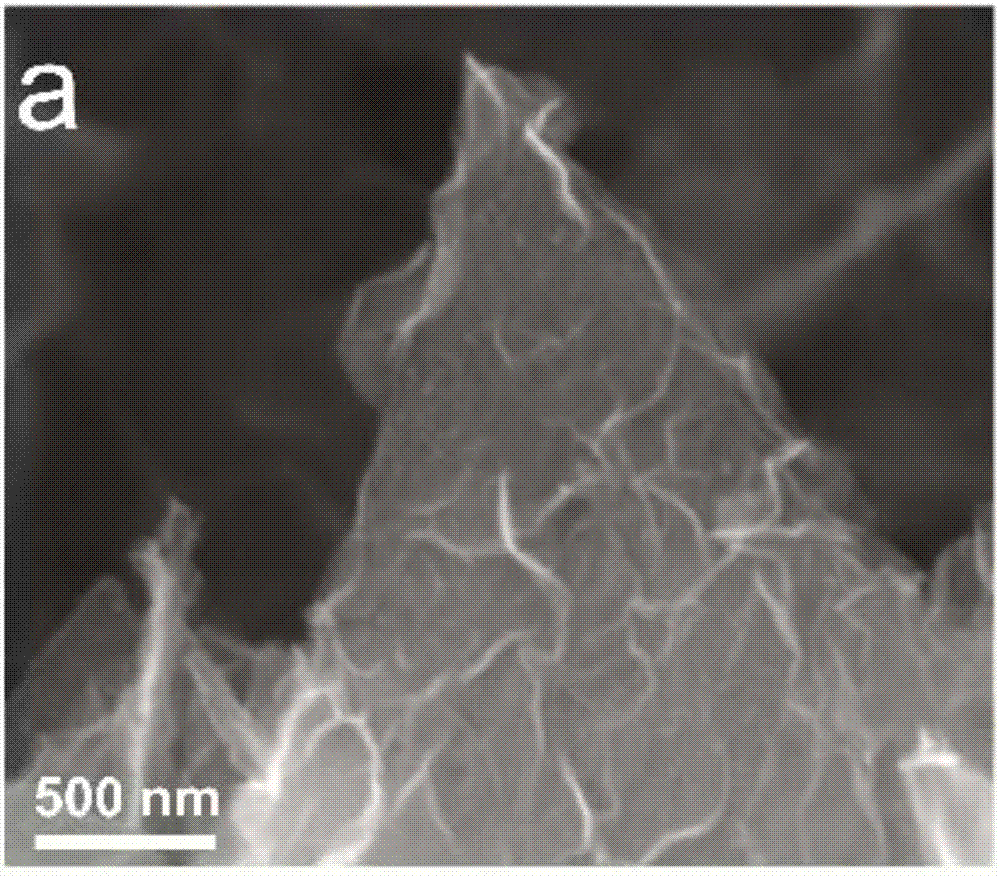

[0041] A nitrogen-doped porous carbon / MoS 2Anode materials for sodium-ion batteries, including conductive carbon cloth as a flexible substrate, a porous nitrogen-doped carbon nanowall array in the middle layer as a skeleton support, and MoS covered on the surface of the porous nitrogen-doped carbon nanowall array 2 Nanosheet group. It is prepared by the following steps:

[0042] Step 1: Preparation of nitrogen-doped porous carbon

[0043] (1) Mix the same volume of 0.4mol / L 2-methylimidazole aqueous solution with 50mmol / L Co(NO 3 ) 2 The aqueous solutions were mixed under stirring.

[0044] (2) Put the clean conductive carbon cloth flexible substrate in the container, and tilt it at an angle of 60° to the bottom of the container, and react at room temperature (25° C.) for 4 hours. After the reaction was finished, it was washed with deionized water and dried in air at 60° C. for 12 hours.

[0045] (3) The sample obtained in the step (2) was calcined at 800 ° C for 2 h in ...

Embodiment 2

[0052] A nitrogen-doped porous carbon / MoS 2 A negative electrode material for a sodium ion battery, which is made through the following steps:

[0053] (1) Mix the same volume of 0.3mol / L 2-methylimidazole aqueous solution with 30mmol / L Co(NO 3 ) 2 The aqueous solutions were mixed under stirring.

[0054] (2) Put the clean conductive carbon cloth flexible substrate in the container, and tilt it at an angle of 60° to the bottom of the container, and react for 2 hours at room temperature (25°C). After the reaction was finished, it was washed with deionized water and dried in air at 60° C. for 12 hours.

[0055] (3) The sample obtained in the step (2) was calcined at 800 ° C for 2 h in an Ar atmosphere, and the heating rate was 1 ° C min -1 , the airflow is 35sscm. After the reaction, the Co-MOF precursor was reduced to a mixture of metallic Co and nitrogen-doped carbon.

[0056] (4) The sample obtained in the step (3) is immersed in a mixed aqueous solution of 3mol / L ferri...

Embodiment 3

[0059] A nitrogen-doped porous carbon / MoS 2 A negative electrode material for a sodium ion battery, which is made through the following steps:

[0060] (1) Mix the same volume of 0.5mol / L 2-methylimidazole aqueous solution with 70mmol / L Co(NO 3 ) 2 The aqueous solutions were mixed under stirring.

[0061] (2) Put the clean conductive carbon cloth flexible substrate in the container, and tilt it at an angle of 60° to the bottom of the container, and react at room temperature (25° C.) for 5 hours. After the reaction was finished, it was washed with deionized water and dried in air at 60° C. for 12 hours.

[0062] (3) The sample obtained in the step (2) was calcined at 800 ° C for 2 h in an Ar atmosphere, and the heating rate was 1 ° C min -1 , the airflow is 35sscm. After the reaction, the Co-MOF precursor was reduced to a mixture of metallic Co and nitrogen-doped carbon.

[0063] (4) The sample obtained in the step (3) is immersed in a mixed aqueous solution of 3mol / L fer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Layer spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com