Preparation method of silage wrapped with sweet sorghum for feeds

A technology of silage and production method, which is applied to the preservation method of animal feed raw materials, animal feed, application, etc., can solve the problems restricting the development of forage sorghum industry, and achieve better and uniform fermentation, uniform moisture content, and rapid Measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

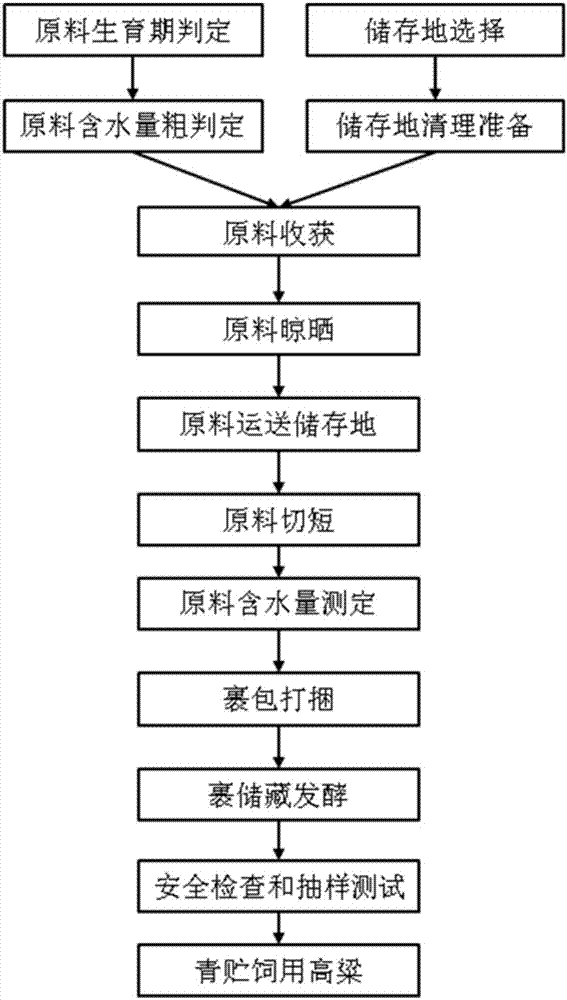

Method used

Image

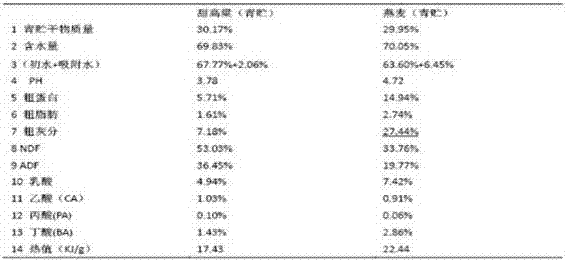

Examples

Embodiment 1

[0053] A method for producing sweet sorghum wrapped silage for feeding, comprising the following steps:

[0054] A. Harvest of raw materials

[0055] During the cutting process of sweet sorghum, there is no debris such as sediment, plastic film, etc., the cutting height is 8-9cm on flat terrain, and 9-10cm on uneven terrain;

[0056] B. Raw material crushing

[0057] The field moisture content of sweet sorghum leaves is 65%-70%, and sent to the pulverizer for shredding, with an average shredding degree of 5-8cm;

[0058] C, drying of raw materials

[0059] Dry in the field, and ensure that the moisture content of sweet sorghum leaves is not less than 60% after drying;

[0060] D. Secondary crushing of raw materials

[0061] Secondary crushing of raw materials, the average crushing degree is 2-3cm;

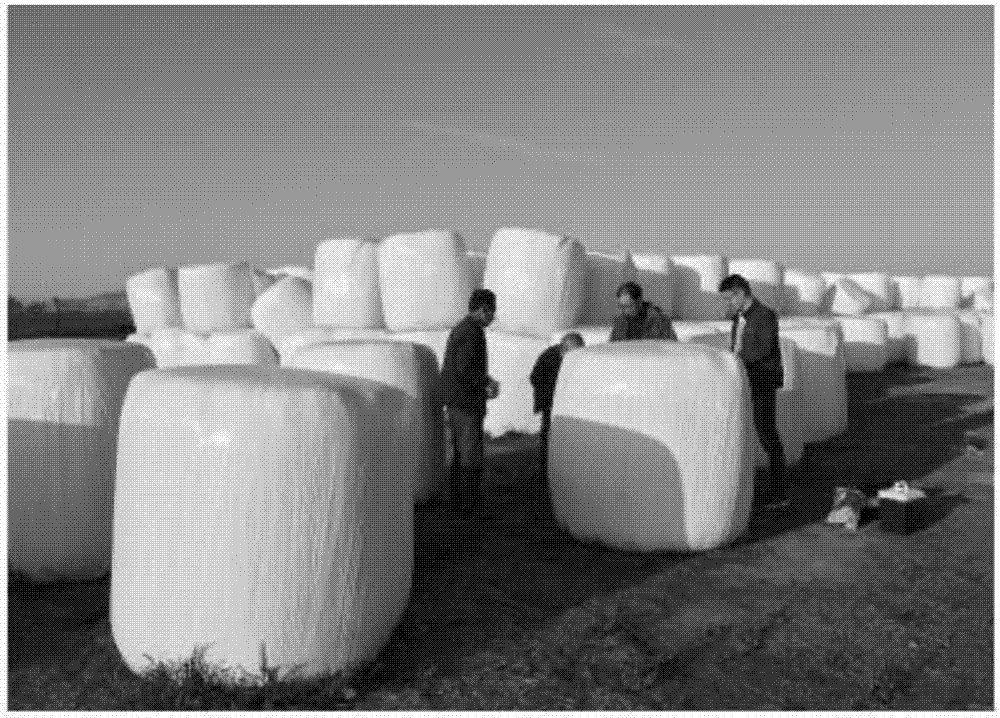

[0062] E. bundling

[0063] The raw materials are bundled with silage entangled nets, and the baling density per cubic meter is more than 600 kilograms; the baling material i...

Embodiment 2

[0069] A method for producing sweet sorghum wrapped silage for feeding, comprising the following steps:

[0070] A. Harvest of raw materials

[0071] During the cutting process of sweet sorghum, there is no debris such as sediment, plastic film, etc., the cutting height is 8-9cm on flat terrain, and 9-10cm on uneven terrain;

[0072] B. Raw material crushing

[0073] To determine the moisture content of raw materials in the field, take 1 leaf of 3-5 plants, roll the leaf and clench the leaf into a ball with the palm of your hand, hold the palm tightly for 10 seconds and then release the palm, and the leaf mass will slowly disperse after 5-10 seconds. Open, send it to the pulverizer for shredding, the average shredding degree is 5-8cm;

[0074] C, drying of raw materials

[0075] Dry in the field, and ensure that the moisture content of sweet sorghum leaves is not less than 60% after drying;

[0076] D. Secondary crushing of raw materials

[0077] Secondary crushing of raw...

Embodiment 3

[0085] A method for producing sweet sorghum wrapped silage for feeding, comprising the following steps:

[0086] A. Harvest of raw materials

[0087] During the cutting process of sweet sorghum, there is no debris such as sediment, plastic film, etc., the cutting height is 8-9cm on flat terrain, and 9-10cm on uneven terrain;

[0088] B. Raw material crushing

[0089] To determine the moisture content of raw materials in the field, take 1 leaf of 3-5 plants, roll the leaf and clench the leaf into a ball with the palm of your hand, hold the palm tightly for 10 seconds and then release the palm, and the leaf mass will slowly disperse after 5-10 seconds. Open, send it to the pulverizer for shredding, the average shredding degree is 5-8cm;

[0090] C, drying of raw materials

[0091] Dry in the field, and ensure that the moisture content of sweet sorghum leaves is not less than 60% after drying;

[0092] D. Secondary crushing of raw materials

[0093] Secondary crushing of raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com