A kind of anti-radiation fabric and its production method

A production method and anti-radiation technology, applied to chemical instruments and methods, protective clothing, layered products, etc., can solve the problems of not being able to use a large area, heavy device weight, and not easy to carry, so as to improve the sense of touch and the production method Reasonable and guaranteed service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

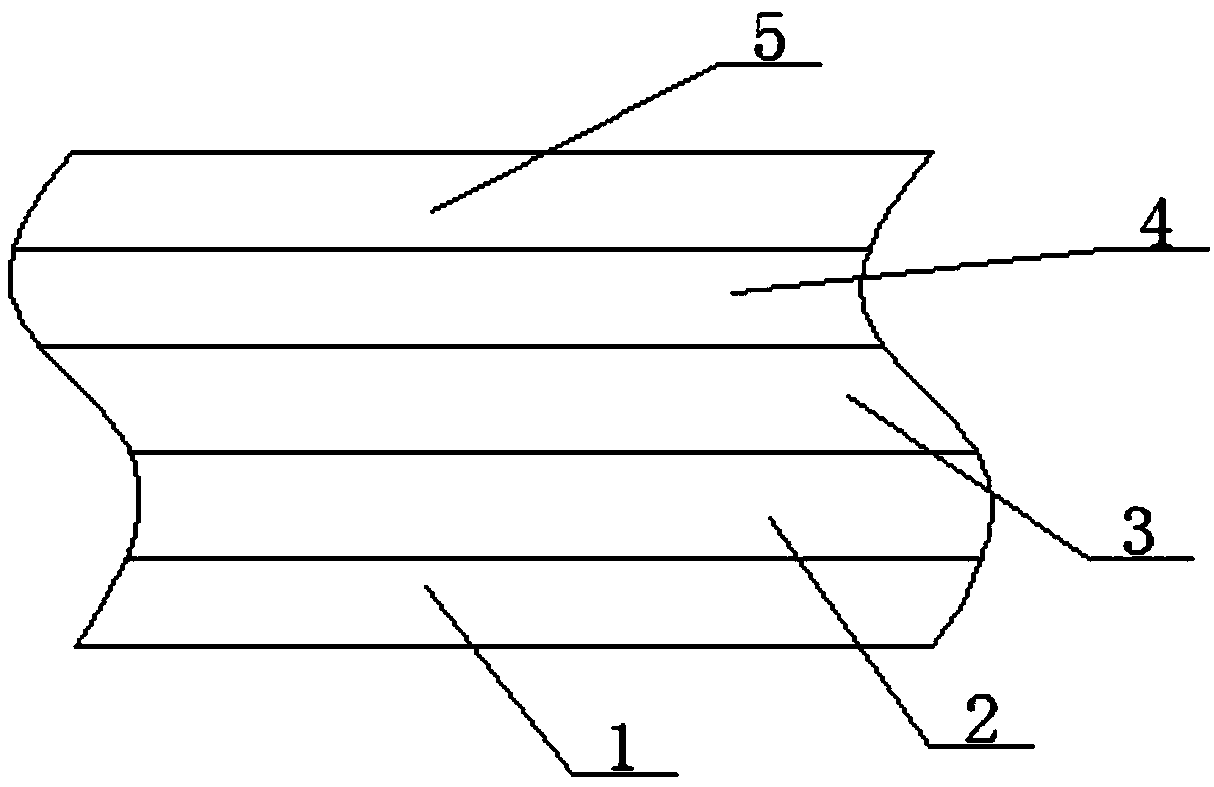

Image

Examples

preparation example Construction

[0039] The preparation process of the anti-radiation resin layer comprises the following steps:

[0040] a, utilize pulverizing device to pulverize beeswax and pearl, make the beeswax powder of 60 orders and the pearl powder of 70 orders;

[0041] b. Add silicone-acrylic emulsion, epoxy resin, polyacrylate, and 3 / 4 deionized water into the heating device for stirring and mixing treatment. The temperature is 60-80°C during stirring and mixing, and the speed is 80-120r / min Stir for 15 minutes, then add polyvinyl alcohol and sodium hydroxide into the heating device in sequence, keep the temperature constant, and stir at a speed of 80-120r / min for 10 minutes;

[0042] c. Grind peach fat and rosin at low temperature, then add the crushed peach fat and 1 / 8 deionized water into a heating container, keep at 60-80°C, and use a stirring device to stir at a speed of 60r / min for 10min to obtain peaches For colloid, add crushed rosin and 1 / 8 deionized water into another heating container,...

Embodiment 1

[0045] The parts by weight of each component in the formula of the anti-radiation resin layer 2 produced according to the preparation process of the above-mentioned anti-radiation resin layer 2 are: 40 parts of silicon acrylic emulsion, 58 parts of epoxy resin, 30 parts of polyacrylate, peach butter 12 parts, 8 parts of rosin, 12 parts of beeswax powder, 11 parts of pearl powder, 40 parts of deionized water, 18 parts of ethyl cellulose, 20 parts of polyvinyl alcohol, 22 parts of nano aluminum hydroxide, 9.5 parts of sodium hydroxide, 13 parts of nano silicon dioxide, 10 parts of talcum powder.

Embodiment 2

[0047] The parts by weight of each component in the formula of the anti-radiation resin layer 2 produced according to the preparation process of the above-mentioned anti-radiation resin layer 2 are: 45 parts of silicon acrylic emulsion, 53 parts of epoxy resin, 25 parts of polyacrylate, peach butter 14 parts, 6 parts of rosin, 14 parts of beeswax powder, 9 parts of pearl powder, 35 parts of deionized water, 16 parts of ethyl cellulose, 22 parts of polyvinyl alcohol, 23 parts of nano aluminum hydroxide, 8.5 parts of sodium hydroxide, 12 parts of nano silicon dioxide, 11 parts of talcum powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com