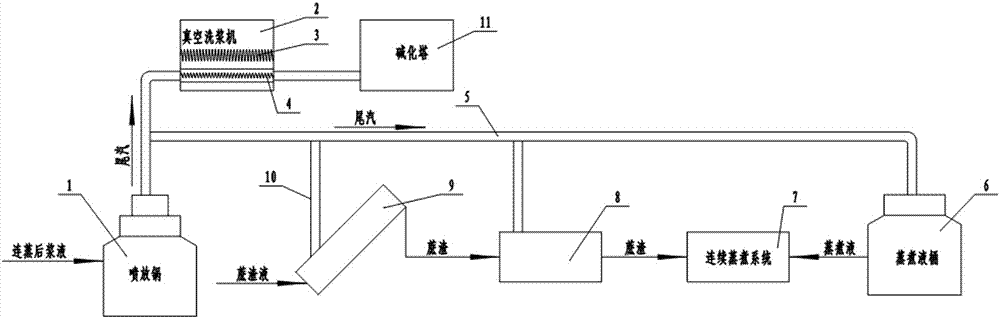

Method for recovery and reuse of tail gas of pulping continuous distillation blowing pot

A technology of tail steam and continuous steaming, which is used in digesters, papermaking, textiles and papermaking, etc., can solve the problems of increasing the amount of fresh steam used, increasing the environmental burden, and burning energy consumption, saving energy consumption and speeding up cooking. time, the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0033] A paper company in Hengxian, Guangxi applied the invention to production practice. Through the invention, 9,104 tons of standard coal can be saved each year, which is equivalent to saving 13,406 tons of raw coal. Based on the raw coal purchase price of 640 yuan / ton in 2014, it can save 8.58 million yuan. The energy-saving effect obtained by implementing the present invention is obvious. It not only saves energy, reduces energy consumption, but also saves energy costs, creates economic benefits for the company, and improves the company's market competitiveness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com