An integrated system for the adjustment and preparation of 2af and of material liquids in the post-treatment process

An integrated system and process flow technology, applied in the field of 2AF and OF material liquid adjustment and preparation integrated system, can solve the problems of inapplicable large-scale continuous processing, low utilization rate of nitrogen oxides, ineffective compatibility of modules, etc., to achieve convenient concentration The effect of automatic management, reduction of manpower, and improvement of overall lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

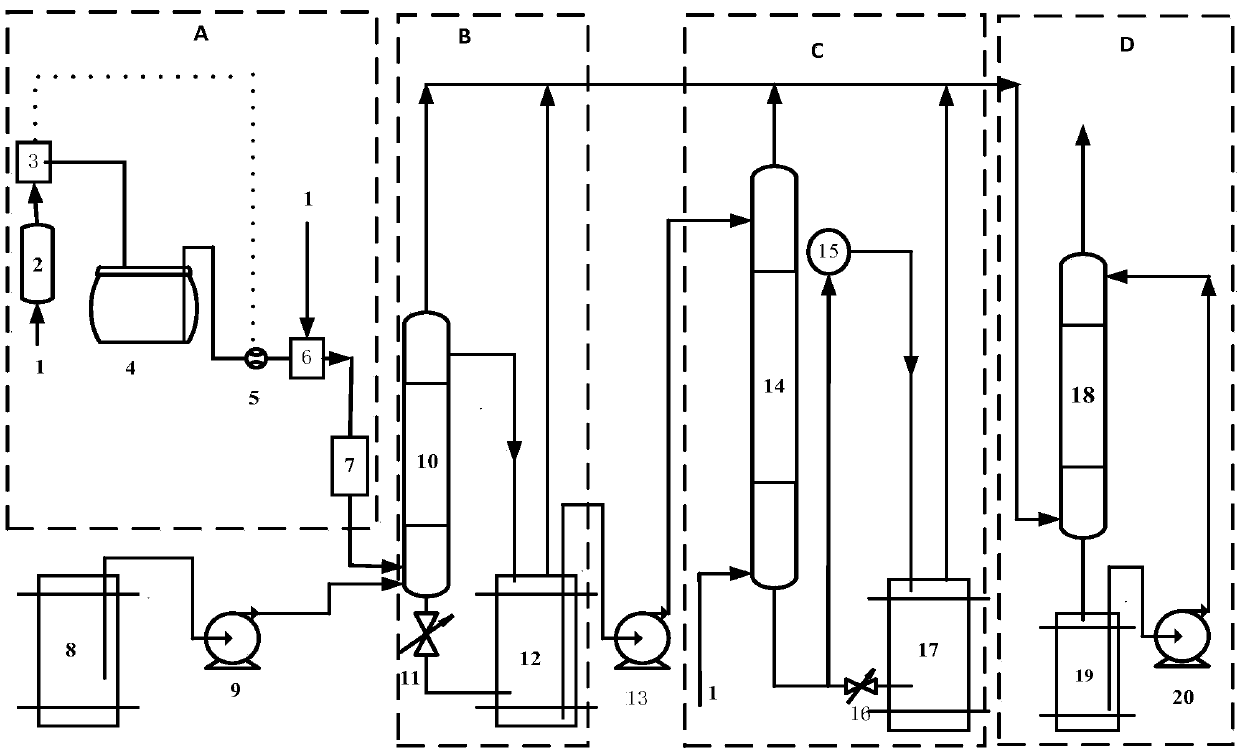

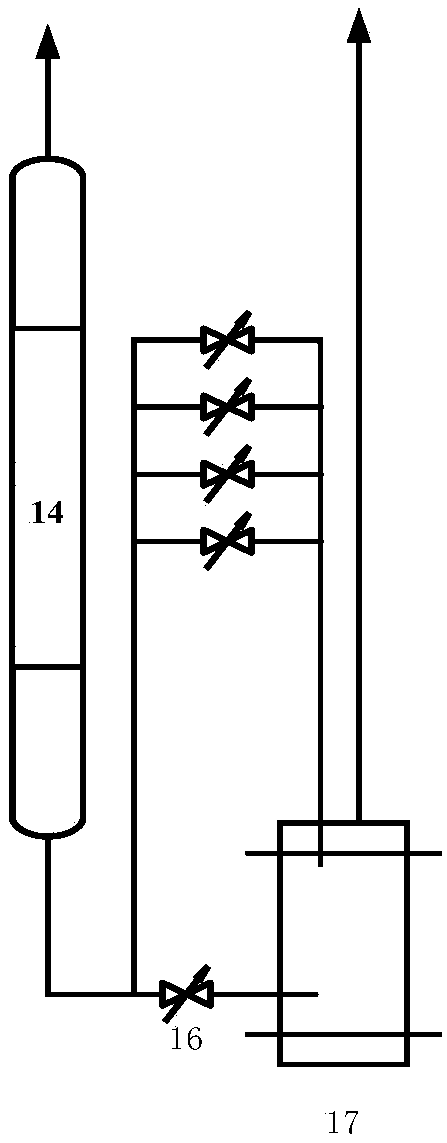

[0036] The entire integrated system is as shown above, and its specific parameters are: the height of the oxidation column is 2000mm, the diameter is 120mm, the filler is Raschig ring (stainless steel material), the particle size is Ф8mm; the height of the degassing column is 4000mm, the diameter is 120mm, the filler Pall ring (stainless steel material) is used, the particle size is Ф8mm; the height of the washing column is 3000mm, the diameter is 150mm, the number is 1, the washing liquid is dilute nitric acid solution; the compressed air pressure is 0.2MPa.

[0037] Based on the established seasoning system, the simulated feed liquid price adjustment experiment was carried out to simulate the replacement of Pu(III) by Fe(II) in the Pu(III) feed liquid, and the feasibility study has been carried out.

[0038] Fe(II) simulated liquid composition: Fe(II) concentration 2g / L, hydrazine concentration 0.1mol / L, hydroxylamine concentration 0.1mol / L, nitric acid concentration 1.5mol / L...

Embodiment 2

[0045] The specific operation is the same as in Example 1, except that the specific parameters are as follows: the height of the oxidation column is 1300mm, the diameter is 60mm, the packing adopts Pall rings (stainless steel material), and the particle size is Ф6mm; 100mm, Raschig ring (stainless steel material) is used as filler, the particle size is Ф10mm; the height of scrubbing column is 2300mm, the diameter is 110mm, the quantity is 1, the washing liquid is dilute nitric acid solution; the compressed air pressure is 1MPa.

[0046] Based on the established seasoning system, the price adjustment experiment of OF simulated feed liquid was carried out, and Fe(II) was used to replace Pu(III) in simulated Pu(III) feed liquid. The feasibility study has been carried out.

[0047] Fe(II) simulated liquid composition: Fe(II) concentration 10g / L, hydrazine concentration 0.4mol / L, hydroxylamine concentration 0.6mol / L, nitric acid concentration 1mol / L, 60L in total.

[0048] Operatin...

Embodiment 3

[0054] The entire integrated system is as shown above, and its specific parameters are: the height of the oxidation column is 1580mm, the diameter is 120mm, the filler is Raschig ring (stainless steel material), the particle size is Ф8mm; the height of the degassing column is 4000mm, the diameter is 150mm, the filler Pall ring (stainless steel material) is used, the particle size is Ф10mm; the height of the washing column is 3000mm, the diameter is 150mm, the number is 1, the washing liquid is dilute nitric acid solution; the compressed air pressure is 0.2MPa.

[0055] Based on the established seasoning system, the simulated feed liquid price adjustment experiment was carried out to simulate the replacement of Pu(III) by Fe(II) in the Pu(III) feed liquid, and the feasibility study has been carried out.

[0056] Fe(II) simulated liquid composition: Fe(II) concentration 3g / L, hydrazine concentration 0.1mol / L, hydroxylamine concentration 0.1mol / L, nitric acid concentration 2.0mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com