Preparation method of core-shell structure nano-rod photocatalyst

A core-shell structure, photocatalyst technology, applied in the field of chemistry, can solve the problems of expensive equipment, uncontrollable nanoshell thickness, and many nanoshell defects, and achieves improved photocatalytic activity, improved photocatalytic activity, and surface coating. tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Add 1mmol of Cd 0.9 Zn 0.1 S nanorods were dispersed in a three-necked bottle containing a mixed solution of 18mL ethylene glycol (EG) and 2mL water, preheated to 90°C in an oil bath and kept warm for 30min;

[0045] 2) will be compared with Cd 0.9 Zn 0.1 Tetrabutyl titanate (TBOT) with an S molar ratio of 0.05 was dissolved in 10 mL of ethylene glycol (EG) and extracted with a 10 mL syringe, and this solution was added to the obtained Cd at a rate of 0.5 mL / h using a mini syringe pump. 0.9 Zn 0.1 S suspension;

[0046] 3) Centrifuge the above solution, and ultrasonically disperse and wash it with deionized water and absolute ethanol until the upper liquid is clear after centrifugation;

[0047] 4) The solid obtained after the above centrifugation was dried in a vacuum oven at 60°C for 10 hours and then ground to obtain TiO 2 @Cd 0.9 Zn 0.1 S core-shell structure nanorod photocatalyst.

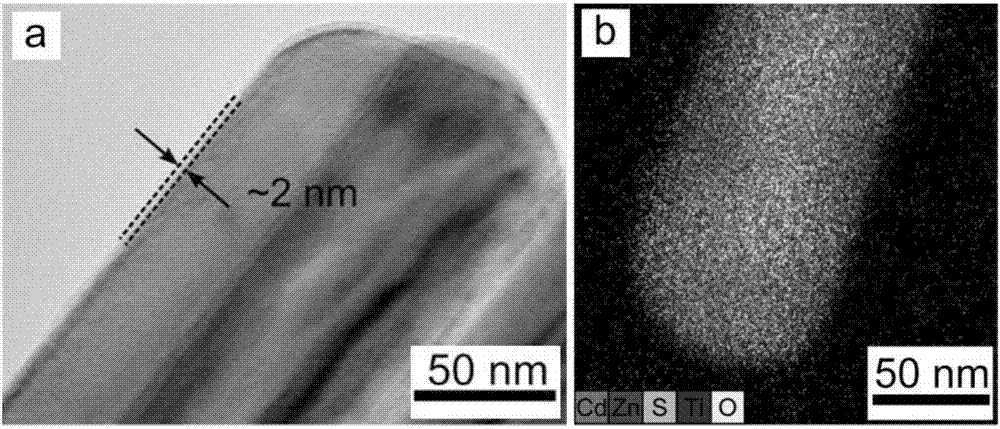

[0048] figure 1 a shows the TiO obtained in Example 1 2 @Cd 0.9 Zn ...

Embodiment 2

[0050] 1) Add 1mmol of Cd 0.9 Zn 0.1 S nanorods were dispersed in a three-necked bottle containing a mixed solution of 18mL ethylene glycol (EG) and 2mL water, preheated to 90°C in an oil bath and kept warm for 30min;

[0051] 2) will be compared with Cd 0.9 Zn 0.1 Tetrabutyl titanate (TBOT) with an S molar ratio of 0.1 was dissolved in 10 mL of ethylene glycol (EG) and extracted with a 10 mL syringe, and this solution was added to the obtained Cd at a rate of 0.5 mL / h using a mini-syringe pump. 0.9 Zn 0.1 S suspension;

[0052] 3) Centrifuge the above solution, and ultrasonically disperse and wash it with deionized water and absolute ethanol until the upper liquid is clear after centrifugation;

[0053] 4) The solid obtained after the above centrifugation was dried in a vacuum oven at 60°C for 10 hours and then ground to obtain TiO 2 @Cd 0.9 Zn 0.1 S core-shell structure nanorod photocatalyst.

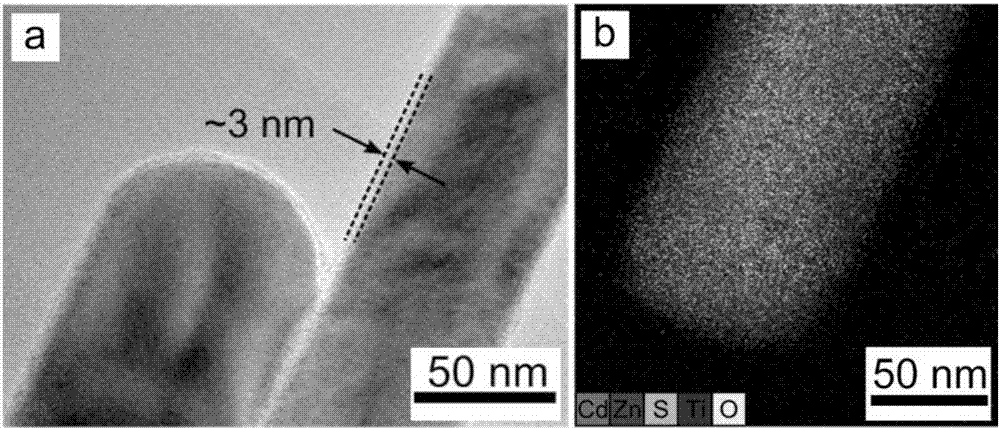

[0054] figure 2 a shows the TiO obtained in Example 2 2 @Cd 0.9 Zn ...

Embodiment 3

[0056] 1) Add 1mmol of Cd 0.9 Zn 0.1 S nanorods were dispersed in a three-necked bottle containing a mixed solution of 18mL ethylene glycol (EG) and 2mL water, preheated to 90°C in an oil bath and kept warm for 30min;

[0057] 2) will be compared with Cd 0.9 Zn 0.1 Tetrabutyl titanate (TBOT) with an S molar ratio of 0.25 was dissolved in 10 mL of ethylene glycol (EG) and extracted with a 10 mL syringe, and this solution was added to the obtained Cd at a rate of 0.5 mL / h using a mini-syringe pump. 0.9 Zn 0.1 S suspension;

[0058] 3) Centrifuge the above solution, and ultrasonically disperse and wash it with deionized water and absolute ethanol until the upper liquid is clear after centrifugation;

[0059] 4) The solid obtained after the above centrifugation was dried in a vacuum oven at 60°C for 10 hours and then ground to obtain TiO 2 @Cd 0.9 Zn 0.1 S core-shell structure nanorod photocatalyst.

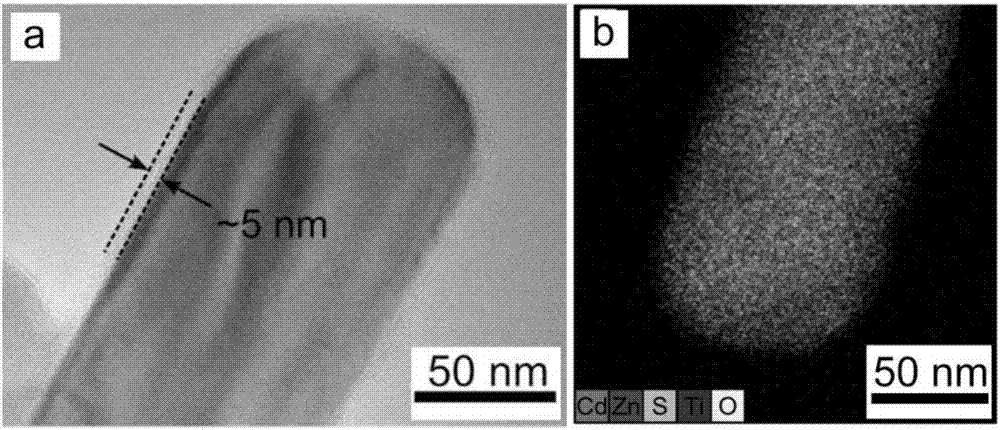

[0060] image 3 a shows the TiO obtained in Example 3 2 @Cd 0.9 Zn 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com