Catalyst for CO gas-phase coupling synthesis of dimethyl carbonate, preparation method and application of the catalyst

A dimethyl carbonate and catalyst technology, applied in the field of organic synthesis, can solve the problems of catalytic performance to be improved, increased processing cost, short service life, etc., and achieve the effects of long service life, improved catalytic performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

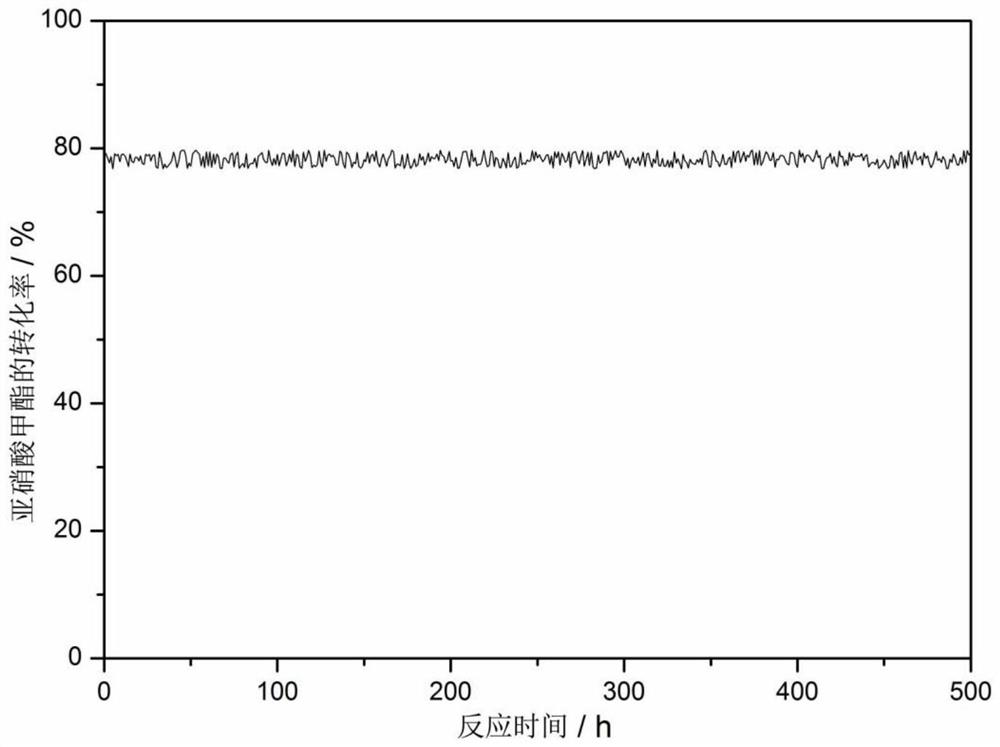

Image

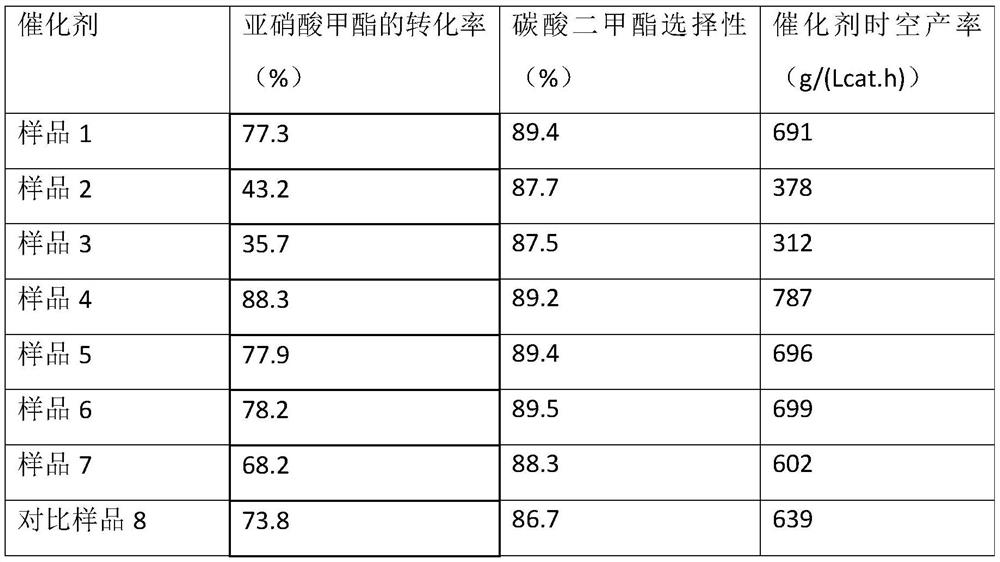

Examples

preparation example Construction

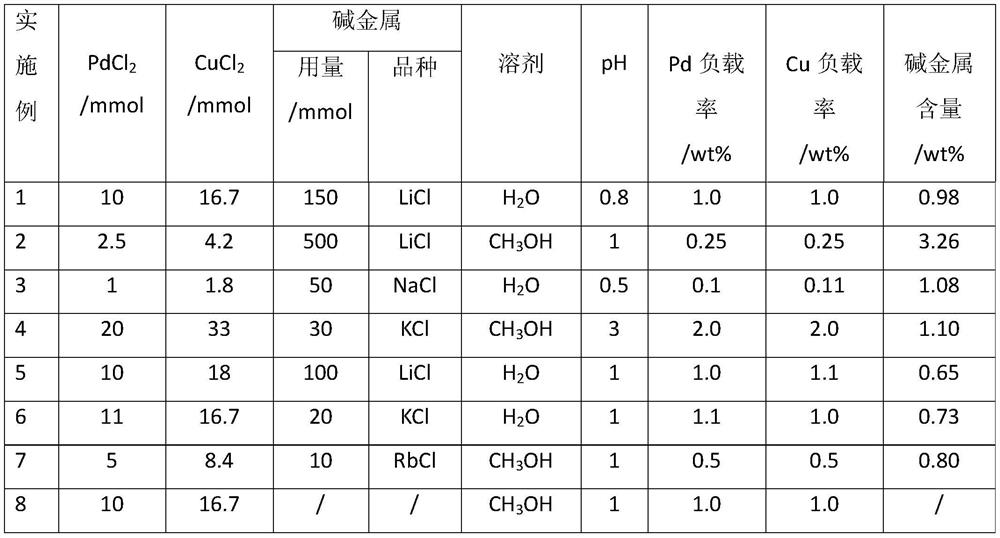

[0031] The preparation method of above-mentioned catalyst, it comprises the following steps:

[0032] 1) PdCl 2 , CuCl 2 , the chloride of the alkali metal element and the solvent are mixed to form a solution, and the solvent is water and / or alcohol, and the chloride of the alkali metal element includes but not limited to lithium chloride, sodium chloride, potassium chloride and rubidium chloride One or more; adding hydrochloric acid to adjust the pH value to 0.5-4;

[0033] 2) Add γ-Al 2 o 3 The carrier is added to the solution in the above steps, dried after immersion at room temperature, and then roasted to obtain the catalyst product; the method of evaporating and drying the solvent is ultrasonic, heating or drying in a drying oven, the roasting temperature is 200 ° C, and the roasting time is more than 2 hours .

[0034] In some embodiments, the PdCl in the step 1) 2 The concentration is 10-500mmol / L, CuCl 2The concentration is 15-800mmol / L, and the concentration o...

Embodiment 1

[0042] 10mmolPdCl 2 , 16.7mmolCuCl 2 , 150mmol lithium chloride, and 100g water were mixed to form a solution, and hydrochloric acid was added to adjust the pH to 0.8. 100g carrier γ-Al 2 o 3 Balls (γ-Al in spherical form 2 o 3 Carrier) was added to the above solution, immersed at room temperature for 48 hours, evaporated and dried in a drying oven at 120°C, and then calcined at 200°C for 10 hours. Catalyst sample No. 1 was obtained, wherein the loading rate of Pd was 1.0wt%, and the loading rate of Cu was 1.0wt%.

Embodiment 2

[0044] 2.5mmolPdCl 2 , 4.2 mmol CuCl 2 , 500mmol lithium chloride, and 100g methanol were mixed to form a solution, and hydrochloric acid was added to adjust the pH to 1. 100g carrier γ-Al 2 o 3 Add the balls into the above solution, soak at room temperature for 48 hours, evaporate and dry in a drying oven at 120°C, and then bake at 200°C for 10 hours. Catalyst sample No. 2 was obtained, wherein the loading rate of Pd was 0.25wt%, and the loading rate of Cu was 0.25wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com