A kind of beneficiation method of high calcium carbonate type fluorite

A beneficiation method and calcium carbonate technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of unsatisfactory high-quality fluorite concentrate, low quality, high calcium carbonate content, etc., and achieve improved flotation Effect, guaranteed recovery rate, effect of highlighting substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

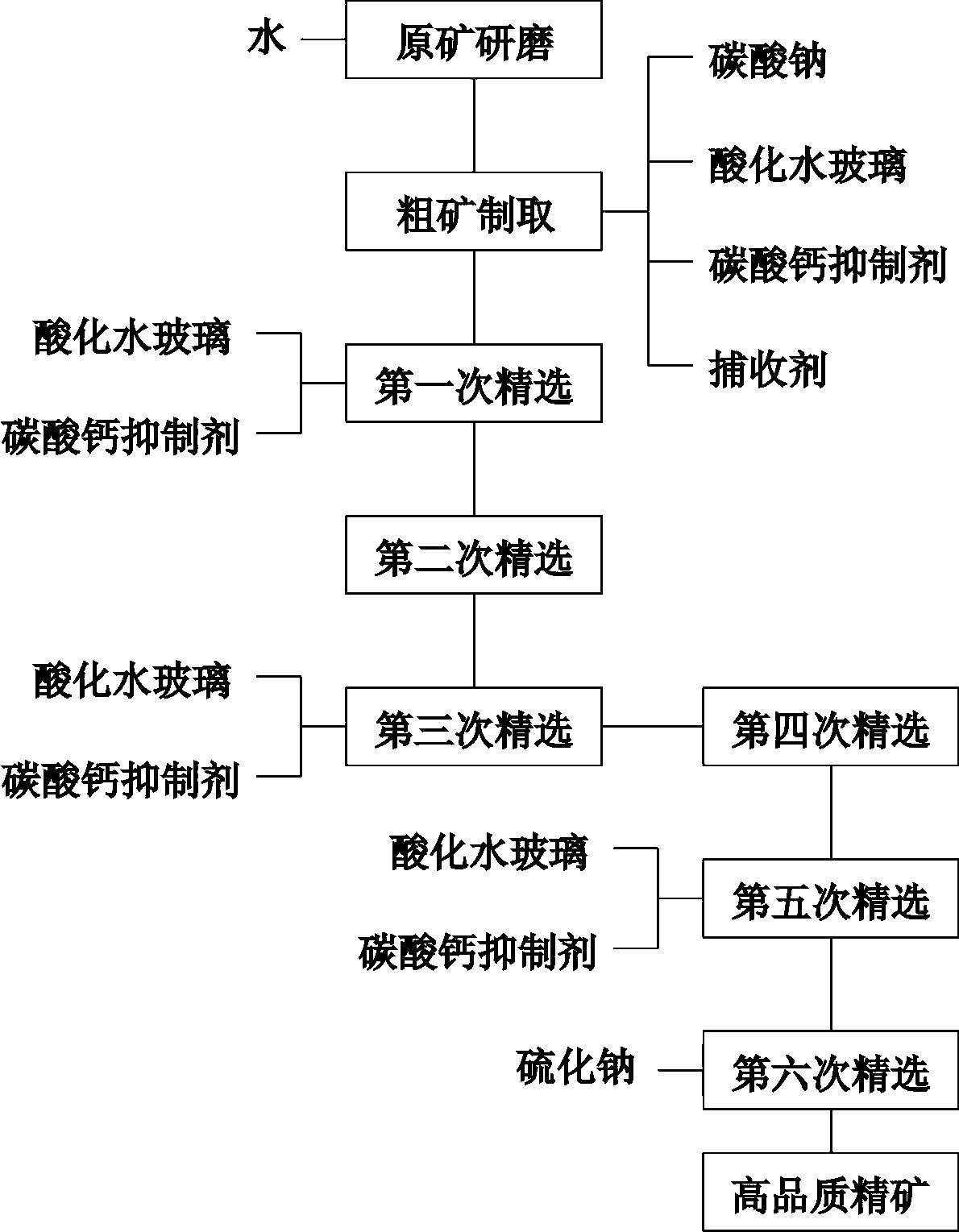

[0022] A kind of beneficiation method of high calcium carbonate type fluorite, comprises the following steps:

[0023] S1. Raw material grinding: Grind the raw ore high calcium carbonate fluorite with a grinder until the particle size is less than 0.074mm, accounting for 55%. During the grinding process, the raw ore is washed with water, and the flow rate of the washing water is kept at 120ml / s to obtain the ore pulp. Take out the impurities in the high calcium carbonate type fluorite raw ore to reduce the impact on ore dressing;

[0024] S2, production of coarse ore concentrate: Put the ore slurry obtained in step S1 into the flotation machine, turn on the flotation machine, and then add sodium carbonate, acidified water glass, calcium carbonate inhibitor and collector in sequence, adding The material interval time is 1min, and the flotation is 6.5min to obtain fluorite coarse concentrate;

[0025] S3, five times of beneficiation process: the fluorite coarse concentrate obta...

Embodiment 2

[0029] A kind of beneficiation method of high calcium carbonate type fluorite, comprises the following steps:

[0030] S1. Raw material grinding: Grind the raw ore high calcium carbonate fluorite with a grinder to a particle size below 0.074mm, accounting for 67%. During the grinding process, the raw ore is washed with water, and the flow rate of the washing water is kept at 135ml / s to obtain the ore pulp. Take out the impurities in the high calcium carbonate type fluorite raw ore to reduce the impact on ore dressing;

[0031] S2, production of coarse ore concentrate: Put the ore slurry obtained in step S1 into the flotation machine, turn on the flotation machine, and then add sodium carbonate, acidified water glass, calcium carbonate inhibitor and collector in sequence, adding The material interval time is 1.5min, and the flotation is 7min to obtain fluorite coarse concentrate;

[0032] S3, five times of beneficiation process: the fluorite coarse concentrate obtained in step...

Embodiment 3

[0036] A kind of beneficiation method of high calcium carbonate type fluorite, comprises the following steps:

[0037]S1. Raw material grinding: Grind the raw ore high calcium carbonate fluorite with a grinder until the particle size is below 0.074mm, accounting for 78%. During the grinding process, the raw ore is washed with water, and the flow rate of the washing water is kept at 150ml / s to obtain the ore pulp. Take out the impurities in the high calcium carbonate type fluorite raw ore to reduce the impact on ore dressing;

[0038] S2, production of coarse ore concentrate: Put the ore slurry obtained in step S1 into the flotation machine, turn on the flotation machine, and then add sodium carbonate, acidified water glass, calcium carbonate inhibitor and collector in sequence, adding The material interval time is 2 minutes, and the flotation is 7.5 minutes to obtain fluorite coarse concentrate;

[0039] S3, five times of beneficiation process: the fluorite coarse concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com