Phosphorus slag-based repairing material for lead polluted soil

A technology for remediating materials and polluted soil, which is applied in the restoration of polluted soil, soil conditioning materials, organic fertilizers, etc., can solve problems such as limited resources, and achieve the effects of low energy consumption, obvious effect and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

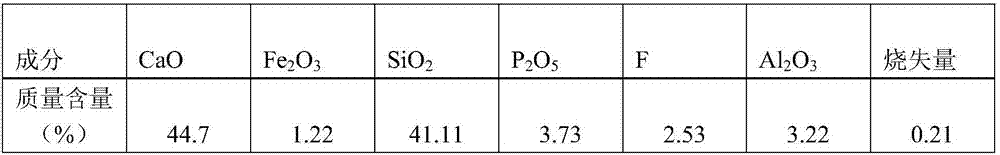

[0022] The ratio of phosphorus slag-based repair materials: phosphorus slag is 70%, boiling slag is 16%, petroleum coke desulfurization ash is 3%, cement kiln dust is 9%, admixture 2.0% (the admixture is composed of potassium laurate 15% , sodium dodecylbenzene sulfonate 23%, sodium lauryl sulfate 36%, sodium lignosulfonate 26% compounded), and then stirred for 30-45 minutes to mix evenly into a repair material.

[0023] The optimal water content of a lead-contaminated soil is 16.7%, and the indoor compaction experiment determined that the minimum content of the contaminated soil remediation material is 5.4%. Use a rotary tiller to till the bottom layer of the contaminated soil at a specified depth, adjust the moisture content of the contaminated soil to the optimum moisture content of 20.7%; then calculate the total amount of phosphorus slag-based restoration materials added based on 7.4% of the dry weight of the contaminated soil, and spray the restoration materials evenly I...

Embodiment 2

[0028] The ratio of phosphorus slag-based repair materials: phosphorus slag is 77%, boiling slag is 9%, petroleum coke desulfurization ash is 10%, cement kiln dust is 2.5%, admixture 1.5% (the admixture is composed of potassium laurate 15% , sodium dodecylbenzene sulfonate 23%, sodium lauryl sulfate 36%, sodium lignosulfonate 26%.), and then stirred for 30-45 minutes to mix evenly into a repair material.

[0029] The optimum moisture content of a lead-contaminated soil is 18.1%, and the minimum content of the remediation material for the contaminated soil is determined to be 7.3% by indoor compaction experiments. Use a rotary tiller to till the bottom layer of the contaminated soil at a specified depth, adjust the moisture content of the contaminated soil to the optimum moisture content of 22.1%; then calculate the total amount of phosphorus slag-based restoration materials added according to 9.3% of the dry weight of the contaminated soil, and spray the restoration materials e...

Embodiment 3

[0034] The ratio of phosphorus slag-based repair materials: 83% of phosphorus slag, 8% of boiling slag, 6% of petroleum coke desulfurization ash, 2% of cement kiln dust, 1.0% of admixture (the admixture is composed of 15% potassium laurate , sodium dodecylbenzene sulfonate 23%, sodium lauryl sulfate 36%, sodium lignosulfonate 26%.), and then stirred for 30-45 minutes to mix evenly into a repair material.

[0035] The optimal moisture content of a lead-contaminated soil is 19.6%, and the minimum content of the remediation material for the contaminated soil is determined to be 9.7% by indoor compaction experiments. Use a rotary tiller to till the bottom layer of the polluted soil to a specified depth, adjust the moisture content of the polluted soil to the optimum moisture content of 23.6%; then calculate the total amount of phosphorus slag-based restoration materials added according to 11.7% of the dry weight of the polluted soil, and spray the restoration materials evenly In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com