Fluorgypsum-based passivator for heavy metal contaminated farmland soil and preparation method of fluorgypsum-based passivator

A passivating agent and gypsum-based technology, applied in the restoration of polluted soil, chemical instruments and methods, soil conditioning materials, etc., can solve the problems of low utilization route and utilization rate, difficult environment and utilization, easy access to water bodies, etc. , to achieve the effect of good quality recovery, large decline and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

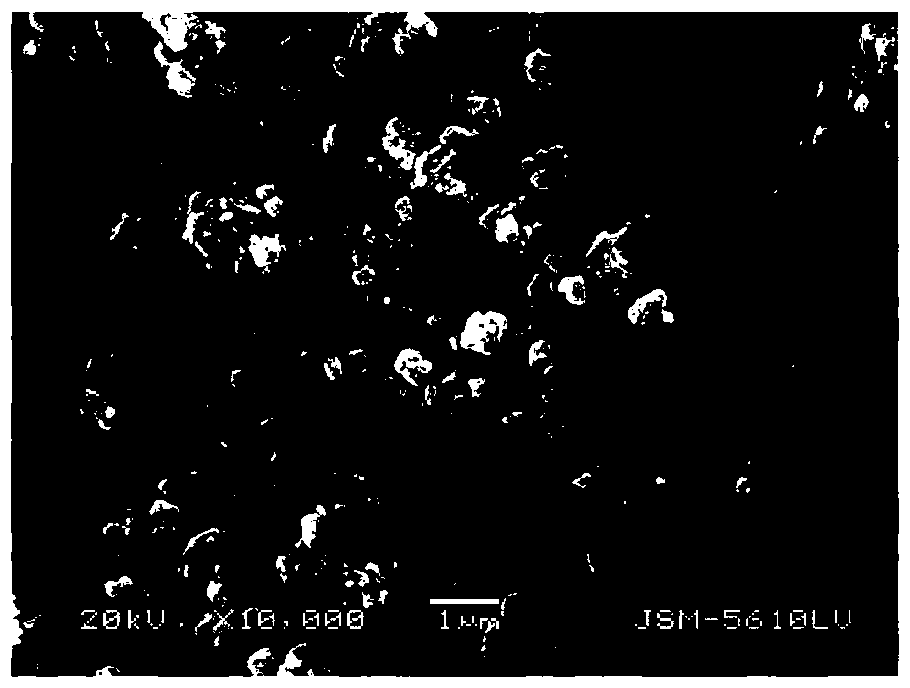

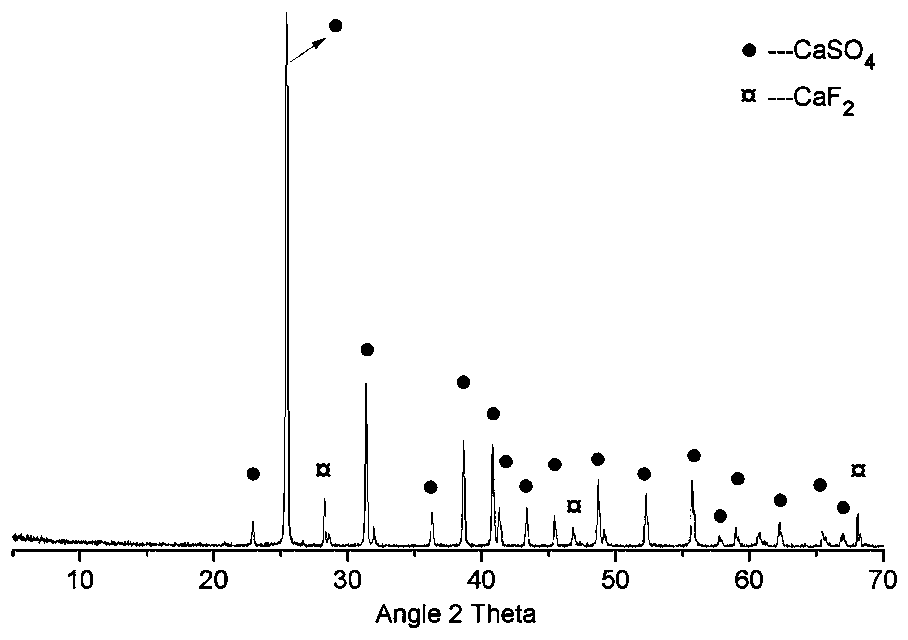

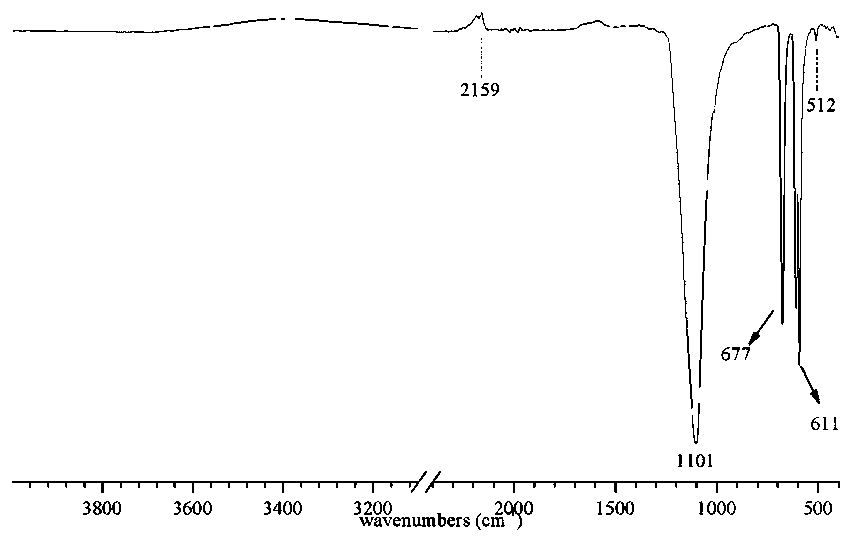

Image

Examples

Embodiment 1

[0024] Fluorogypsum-based passivation agent ratio: based on 30% fluorogypsum, add 24% blast furnace manganese slag, 25% steel slag, 15% phosphorous tailings, 3.0% white mud, mix and stir for 30-45 minutes, after 24 hours of stuffing Add 3% admixture (25% carboxymethyl cellulose, 10% sodium dodecylbenzene sulfonate, 9% lauryl alcohol, 16% acetyl dodecylamine, 40% melamine compound), and then mix the mixture Grind in a ball mill for 40 minutes to prepare a fluorogypsum-based passivator.

[0025] The heavy metal content in the soil of a polluted farmland is shown in the table below. Add 1100kg of passivator per mu to the polluted soil for remediation. Steel slag and white mud are OH under the action of water dissolution. - will dissolve, and the alkalinity of the solution will increase rapidly, which will promote the dissolution of anhydrous calcium sulfate in fluorogypsum, Ca 2+ and SO 4 2- Entering the solution, it also promotes the destruction of the vitreous structure of a...

Embodiment 2

[0029] Fluorogypsum-based passivation agent ratio: based on 50% fluorogypsum, add 16% blast furnace manganese slag, 22% steel slag, 6% phosphorus tailings, 5.0% white mud and mix for 30-45 minutes. Add 1% admixture (15% carboxymethyl cellulose, 8% sodium dodecylbenzene sulfonate, 5% lauryl alcohol, 40% acetyl dodecylamine, 32% melamine compound), and then mix the mixture Grind in a ball mill for 40 minutes to prepare a fluorogypsum-based passivator.

[0030] The heavy metal content of a polluted farmland soil is shown in the following table. 980kg of passivating agent per mu is added to the polluted soil for restoration. Steel slag and white mud are dissolved in water to dissolve OH - will dissolve, and the alkalinity of the solution will increase rapidly, which will promote the dissolution of anhydrous calcium sulfate in fluorogypsum, Ca 2+ and SO 4 2- Entering the solution, it also promotes the destruction of the vitreous structure of a large number of silicon-aluminum mine...

Embodiment 3

[0034] Fluorogypsum-based passivation agent ratio: based on 45% fluorogypsum, add 20% blast furnace manganese slag, 18% steel slag, 10% phosphorous tailings, 4.0% white mud, mix and stir for 30-45 minutes, after 24 hours of stuffing Add 3% admixture (compounded by 20% carboxymethyl cellulose, 7% sodium dodecylbenzene sulfonate, 6% dodecyl alcohol, 33% acetyl dodecylamine, 34% melamine), and then mix The materials were pulverized in a ball mill for 40 minutes to prepare a fluorogypsum-based passivator.

[0035] The heavy metal content in the soil of a polluted farmland is shown in the table below. 850kg of passivating agent per mu is added to the contaminated soil for restoration. Steel slag and white mud are OH under the action of water dissolution. - will dissolve, and the alkalinity of the solution will increase rapidly, which will promote the dissolution of anhydrous calcium sulfate in fluorogypsum, Ca 2+ and SO 4 2- Entering the solution, it also promotes the destructio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com