Highly-enriched laundry sheet and preparation method thereof

A laundry tablet and high-concentration technology, applied in the field of daily chemical products, can solve the problems of wasted transportation cost, bulky, and occupying space of packaging materials, and achieves the effect of being beneficial to storage and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A highly concentrated laundry tablet, comprising the following components by weight: 40 parts of sodium α-olefin sulfonate, 20 parts of fatty alcohol polyoxyethylene ether, 8 parts of polyvinyl alcohol, 3 parts of glycerin, magnesium stearate 5 parts, 0.5 part of disodium EDTA, 0.01 part of triclocarban, 0.001 part of essence.

[0019] The preparation method of the above-mentioned highly concentrated laundry tablet comprises the following steps: step 1, mixing polyvinyl alcohol and glycerin, dissolving them together in 60 parts of water, and stirring to obtain composition 1; step 2, mixing magnesium stearate, EDTA After sodium, disodium EDTA and essence are evenly mixed, add sodium α-olefin sulfonate and fatty alcohol polyoxyethylene ether to obtain composition 2; step 3, spray composition 1 into composition 2, and continuously stir to obtain composition 2 Three; step 4, the composition three is pressed through a tablet press to obtain a semi-finished product, wherein t...

Embodiment 2

[0021] A highly concentrated laundry tablet, comprising the following components by weight: 40 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 5 parts of ester quaternary ammonium salt, 5 parts of cocamidopropyl betaine, and 10 parts of ethanol , 1 part of sodium polyacrylate, 3 parts of polyvinyl alcohol, 3 parts of diatomaceous earth, 5 parts of zeolite powder, 0.01 part of essence, 0.1 part of protease, and 0.1 part of lipase.

[0022] The preparation method of the above-mentioned highly concentrated laundry tablet includes the following steps: Step 1, after dispersing polyvinyl alcohol and sodium polyacrylate in ethanol, add 60 parts of water together and stir to obtain composition 1; Step 2, mix diatomaceous earth, zeolite After the powder, essence, protease and lipase are evenly mixed, add fatty alcohol polyoxyethylene ether sodium sulfate, ester quaternary ammonium salt, and cocamidopropyl betaine to obtain composition 2; step 3, spray strong composition 1 t...

Embodiment 3

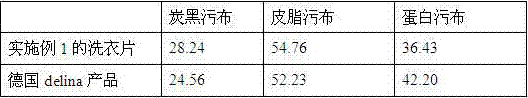

[0024] Take the laundry tablet of Example 1 and the German denila super-concentrated laundry tablet of the same weight, wash protein stained cloth, carbon black stained cloth, and sebum stained cloth under the same conditions, compare the decontamination effect, and compare it to different stains decontamination ability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com