A water-phase electrodeposition device and its application to the method for preparing uranium targets on the front and back sides of a tantalum sheet

An electrodeposition device and electrodeposition technology are applied in the field of electrodeposition technology, and can solve the problems of inability to quantify the thickness of a uranium layer, easy peeling of a uranium target uranium layer, cumbersome experimental operations, and the like, achieving a concise structure, environmental friendliness, and high deposition efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

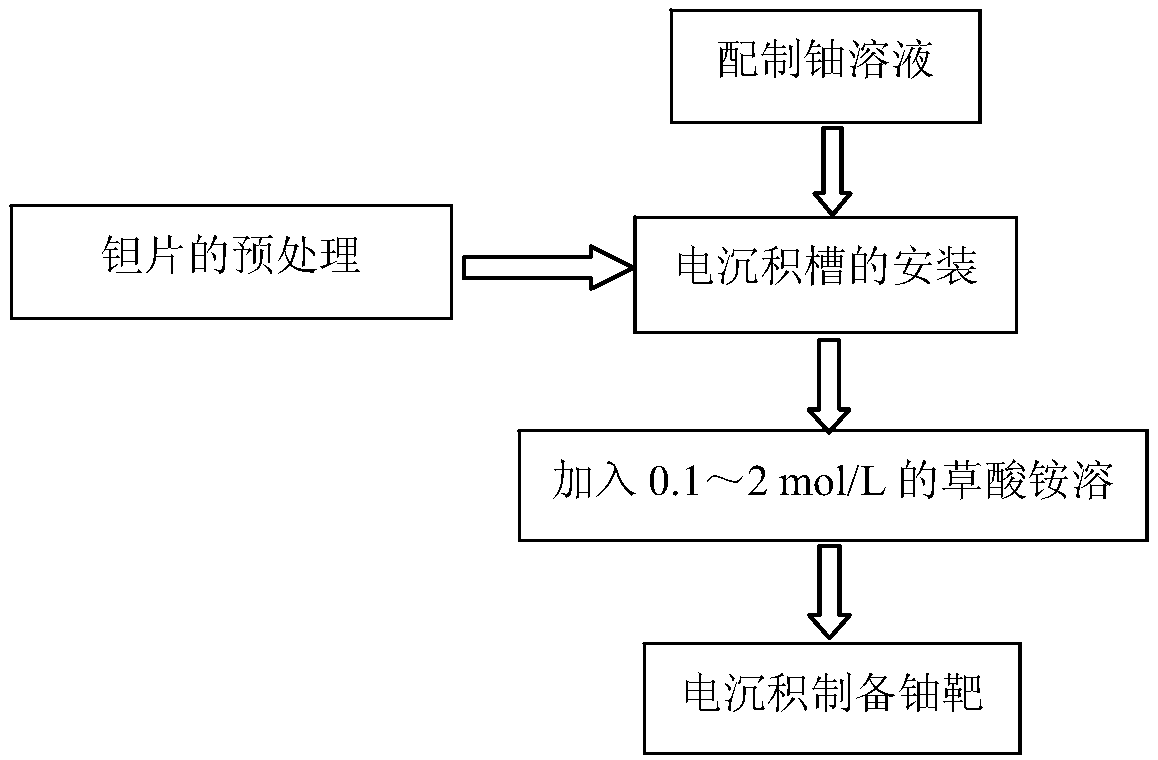

Method used

Image

Examples

Embodiment 1

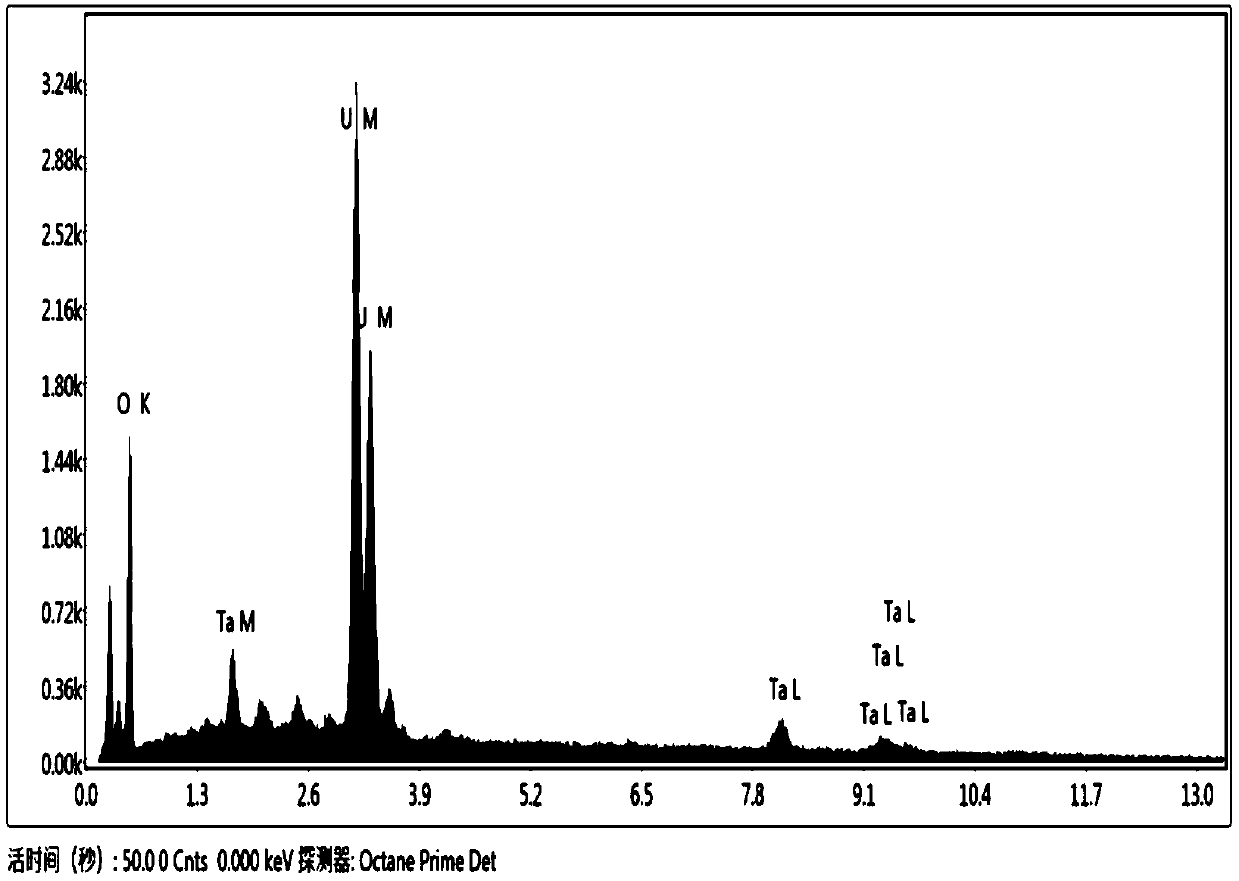

[0039] 1, 238 U solution is prepared by dissolving uranium material (such as analytically pure uranyl nitrate) 238 U solution, heated to dissolve with concentrated nitric acid and continued to heat and evaporate to near dryness, destroyed the organic matter in it with concentrated nitric acid and hydrogen peroxide, and evaporated to dryness, and used 1mol / L HNO 3 Dissolved and adjusted to a volume of 50g / L 238 U solution.

[0040] 235 U solution is prepared by dissolving uranium material 235 U solution (concentration is 50g / L, its uranium abundance is measured by thermal ionization mass spectrometer).

[0041] Choose a uranium solution as needed.

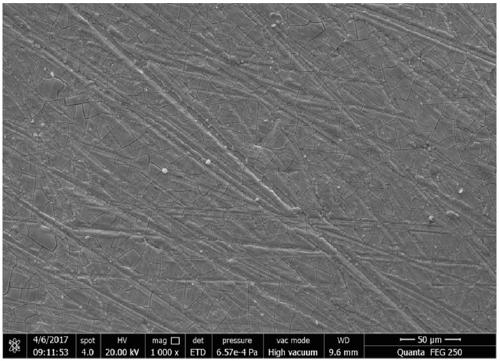

[0042] 2. Tantalum sheet pretreatment process: use 400# metallographic sandpaper for roughening treatment, 800# metallographic sandpaper for grinding and polishing, heat and soak with 1-10% sodium hydroxide for 10-15min, wash with deionized water, Finally, it was cleaned with acetone and loaded into an electrodeposition appara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com