Inclined wire papermaking apparatus

A technology of papermaking equipment and inclined wire, which is applied in the direction of papermaking, papermaking machines, textiles and papermaking, etc. It can solve the problems of poor paper evenness, poor precision, large mesh deformation, etc., and achieves the effect of good wear resistance and guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

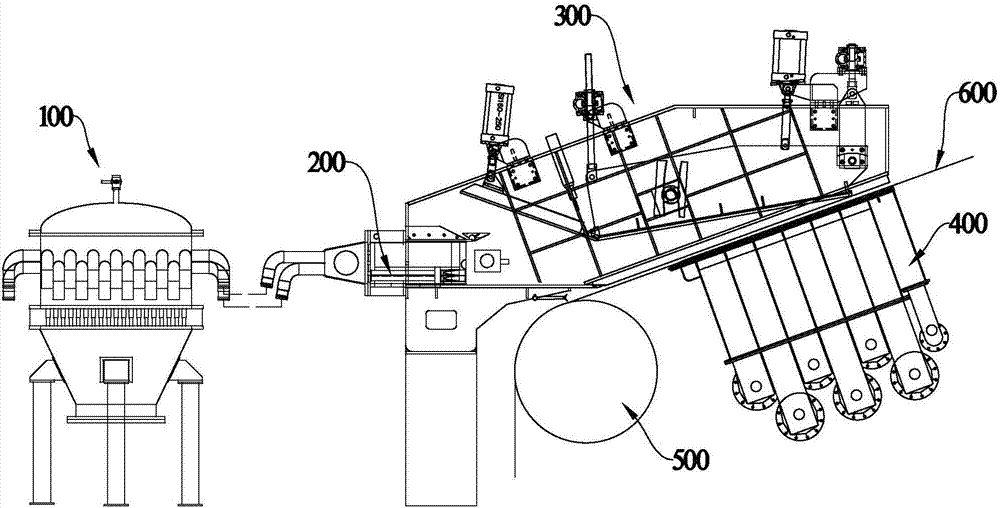

[0046] Such as Figures 1 to 16 As shown, an embodiment of the present invention includes an isobaric slurry tank 100 , a stainless steel slurry distributor 200 , an inclined wire headbox 300 , a dewatering box 400 , a breast roll 500 and a forming wire 600 . details as follows:

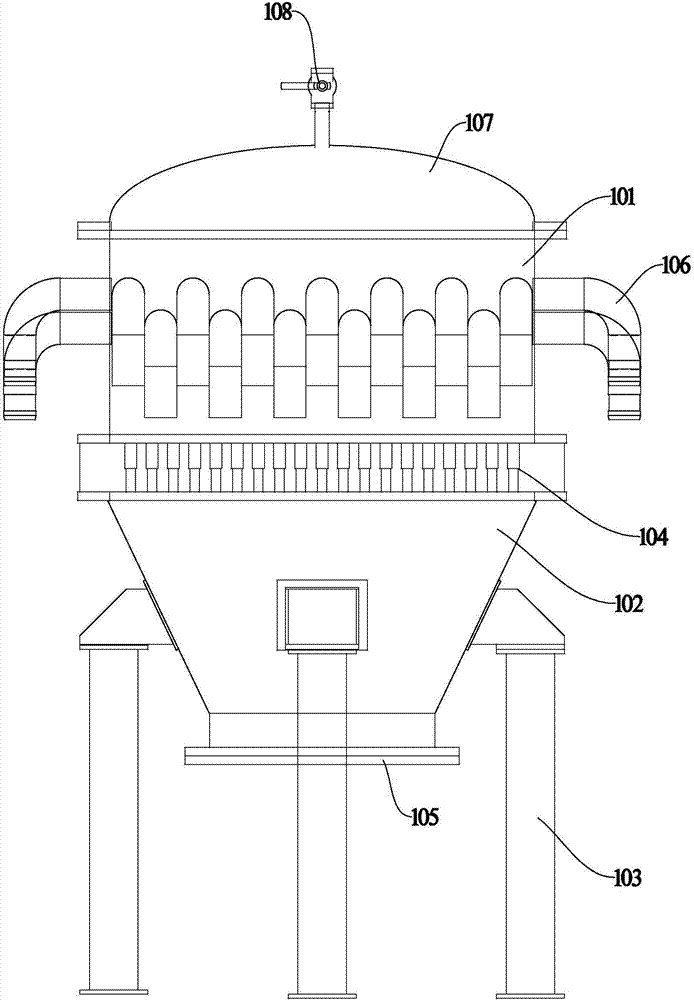

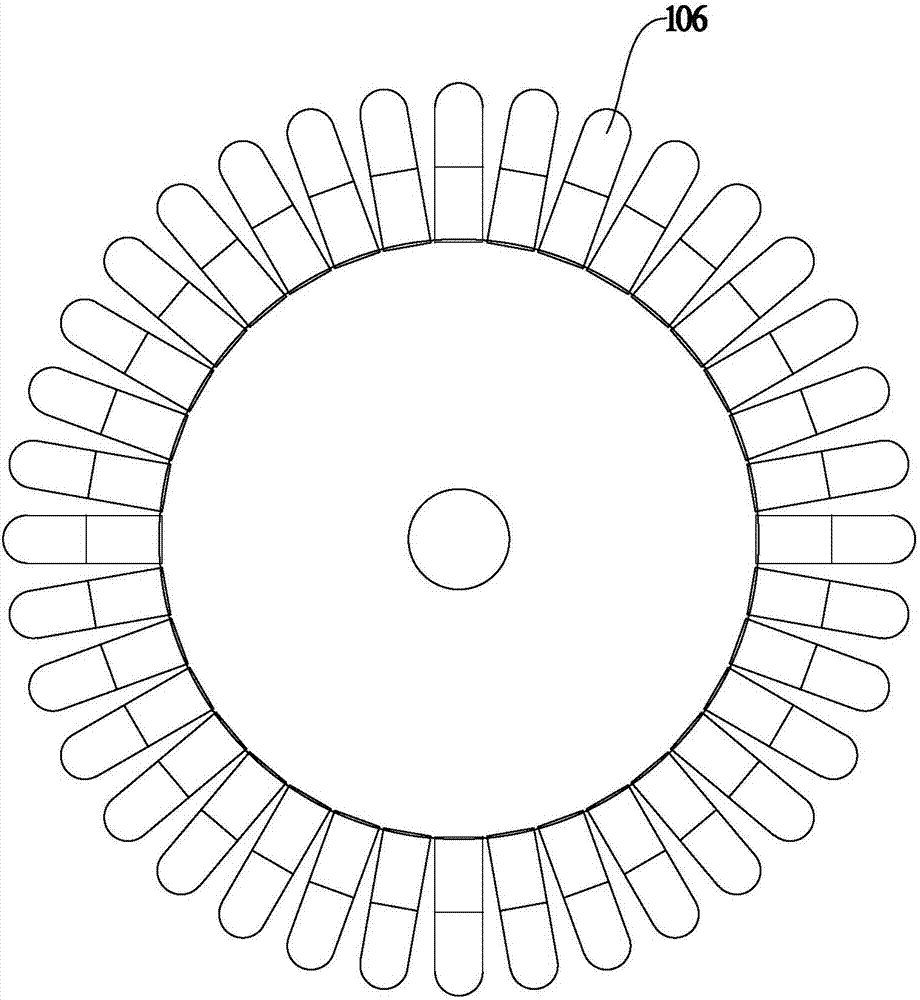

[0047] The isobaric slurry tank 100 includes an upper tank body 101, a lower tank body 102, legs 103 and an orifice plate 104, the orifice plate 104 is arranged between the upper tank body 101 and the lower tank body 102, and the legs 103 support the upper tank body 101 and the lower tank body 102, the lower end of the lower tank body 102 is provided with a slurry inlet 105, and a plurality of slurry outlet joints 106 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com