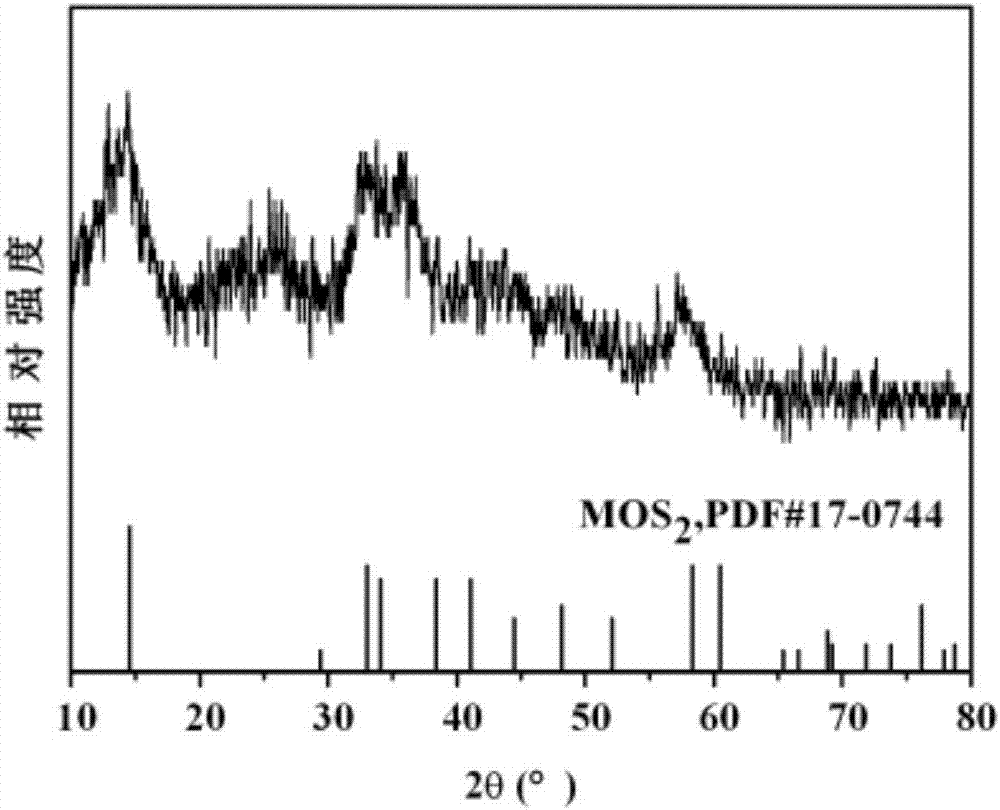

Molybdenum disulfide-graphene aerogel electrode material preparation method

A graphene airgel and electrode material technology, applied in graphene, battery electrodes, secondary batteries, etc., can solve the problems of difficult process control, high production cost, complicated preparation process, etc., and achieve good electrical conductivity and thermal conductivity The effect of high efficiency, simple and environmentally friendly preparation method, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

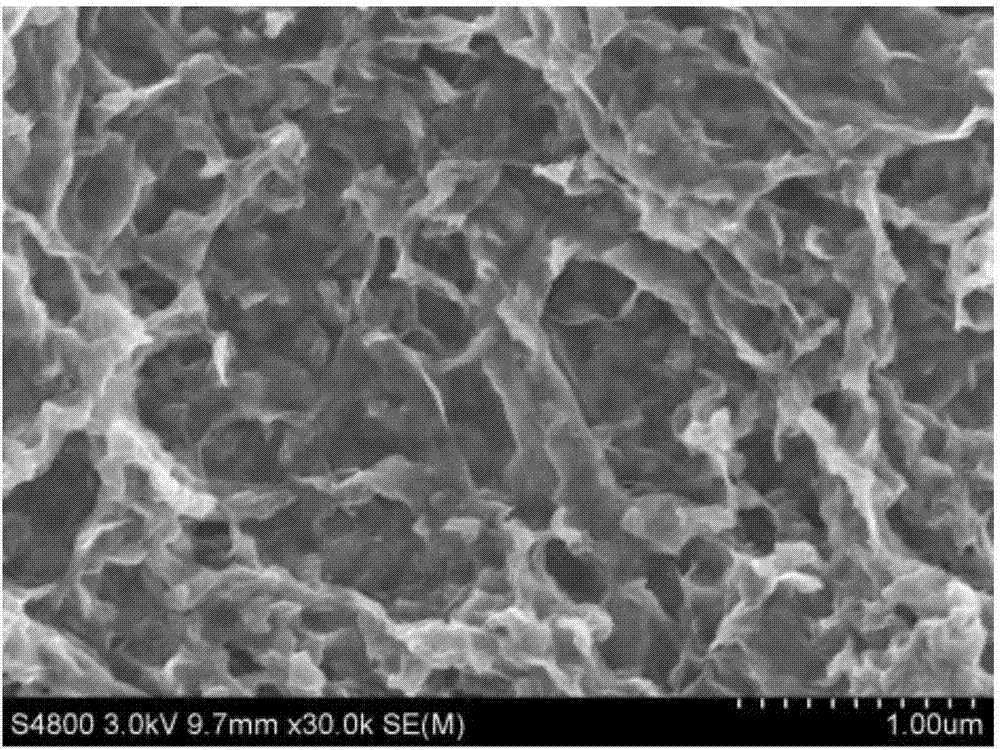

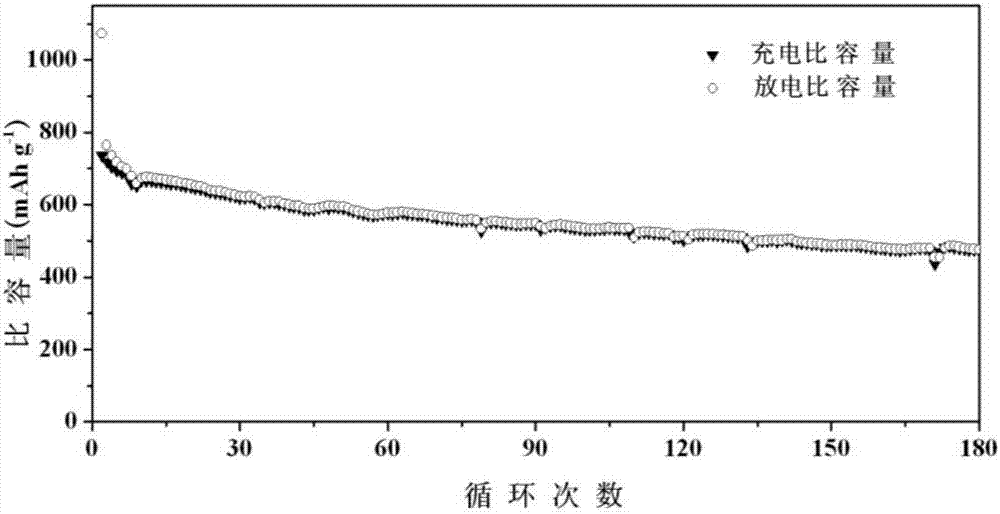

Embodiment 1

[0033] Add 2mmol of molybdenum trioxide and 10mg of graphene oxide into 300mL of distilled water, disperse for 12h and make it uniform under the conditions of ultrasonic power of 300W and ultrasonic temperature of 25°C to obtain an intermediate solution; then add 1mmol of thiourea to the intermediate solution Stir for 30 minutes at a rotation speed of 700r / min until evenly mixed to obtain a mixed solution; transfer the mixed solution to a polytetrafluoroethylene hydrothermal lining and put it into an oven with a filling ratio of 60%, and conduct a hydrothermal reaction at a temperature of 180°C for 24 hours After the reaction was completed, it was naturally cooled to room temperature, centrifuged and washed three times with deionized water and absolute ethanol, and the precipitate was separated. The separated precipitate was taken out and freeze-dried under vacuum conditions. The freezing temperature was -40 ° C, and the freezing time was After 24 hours, the molybdenum disulfid...

Embodiment 2

[0035] Add 3mmol of molybdenum trioxide and 20mg of graphene oxide into 300mL of distilled water, ultrasonically disperse for 12h under the conditions of ultrasonic power of 300W and ultrasonic temperature of 25°C, and make it uniform to obtain an intermediate liquid; then add 2mmol thiourea was stirred at a speed of 700r / min for 30min until uniformly mixed to obtain a mixed solution; the mixed solution was transferred to a polytetrafluoroethylene hydrothermal lining and placed in an oven with a filling ratio of 60%, and the water was heated at a temperature of 180°C Heat the reaction for 24 hours, cool down to room temperature naturally after the reaction, centrifuge and wash 3 times with deionized water and absolute ethanol, separate the precipitate, take out the separated precipitate and freeze-dry under vacuum conditions, the freezing temperature is -40 ° C, The freezing time is 24 hours, and the molybdenum disulfide / graphene airgel electrode material is obtained.

Embodiment 3

[0037] Add 6mmol of molybdenum trioxide and 30mg of graphene oxide into 300mL of distilled water, ultrasonically disperse for 12 hours under the conditions of ultrasonic power of 300W and ultrasonic temperature of 25°C and make it uniform to obtain an intermediate solution; then add 2mmol to the intermediate solution Thiourea, stirred at 700r / min for 30 minutes until uniformly mixed to obtain a mixed solution; transferred the mixed solution to a polytetrafluoroethylene hydrothermal lining and put it into an oven with a filling ratio of 60%. Heat the reaction for 18 hours, cool to room temperature naturally after the reaction, centrifuge and wash 3 times with deionized water and absolute ethanol, separate the precipitate, take out the separated precipitate and freeze-dry under vacuum conditions, the freezing temperature is -40 ° C, The freezing time is 24 hours, and the molybdenum disulfide / graphene airgel electrode material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com