Preparation method of three-dimensional porous graphene modified LFP powder

A graphene-modified, three-dimensional porous technology, used in electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as low performance at large rates, reduce side reactions, improve diffusion rates, and achieve good electrochemical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

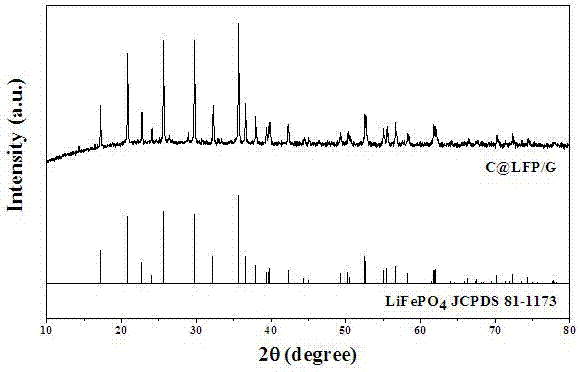

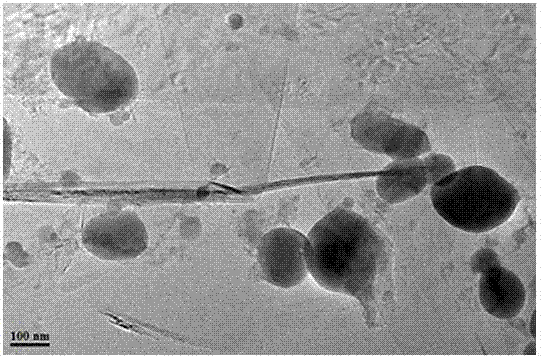

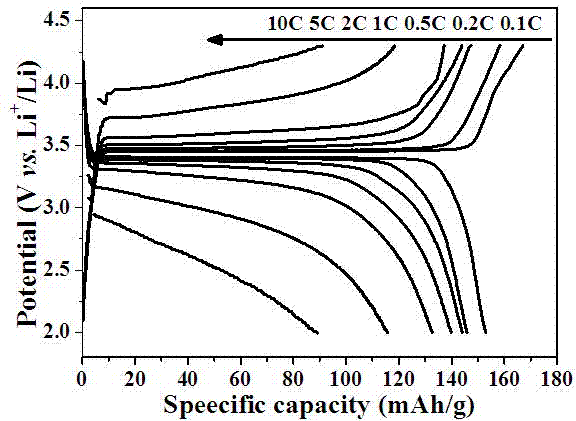

[0033] Example 1: A preparation method of C@LFP / G (1% G), the steps are as follows:

[0034] a. The raw material FeC 2 o 4 2H 2 O, NH 4 h 2 PO 4 、LiCO 3 With acetone according to the ratio of 3.6g: 2.3g: 0.74g: 40g, add 0.63g of glucose, add 0.063g of graphene, perform intermittent high-speed ball milling in a high-energy ball mill, run for 10 minutes every time, intermittently for 30 s, and then reverse For 10 minutes, choose a ceramic ball mill pot, the material ball is Φ 5 mm agate ball, the ball material ratio is 3:10, the control speed is 600 r / min, and the time is 6 hours to form a rheological phase mixture;

[0035] b. volatilize the acetone from the rheological phase mixture obtained in step (a) at 50° C. in a blast drying oven to form a solid precursor;

[0036] c. Put the solid precursor obtained in step (b) into a vacuum drying oven, set the temperature at 80°C, dry it in vacuum for 20 hours, and cool it down to room temperature naturally to obtain a flaky soli...

Embodiment 2

[0043] Example 2: A preparation method of a C@LFP / G (3% G) composite material, the steps are as follows:

[0044] a. The raw material FeC 2 o 4 2H 2 O, NH 4 h 2 PO 4 、LiCO 3 With acetone according to the ratio of 3.6g: 2.3g: 0.74g: 40g, add 0.63g of glucose, 0.19g of graphene in a high-energy ball mill for intermittent high-speed ball milling, every 10 minutes of operation, intermittent 30s, and then reverse 10 min, choose a ceramic ball mill pot, the material ball is Φ 5 mm agate ball, the ball material ratio is 3:10, the control speed is 600 r / min, and the time is 6 h to form a rheological phase mixture;

[0045] b. volatilize the acetone from the rheological phase mixture obtained in step (a) at 50° C. in a blast drying oven to form a solid precursor;

[0046] c. Put the solid precursor obtained in step (b) into a vacuum drying oven, set the temperature at 80°C, dry it in vacuum for 20 hours, and cool it down to room temperature naturally to obtain a flaky solid prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com