Magnesium oxide secondary electron emission film doped with metal and aluminum oxide and preparation method thereof

A secondary electron emission, magnesium oxide technology, applied in metal material coating process, sputtering coating, vacuum evaporation coating and other directions, can solve the problem of restricting the secondary electron emission performance of magnesium oxide composite film and reducing the secondary electron emission Electron emission coefficient and other issues, to achieve the effect of suppressing surface charging effect, improving electron transport characteristics, and reducing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

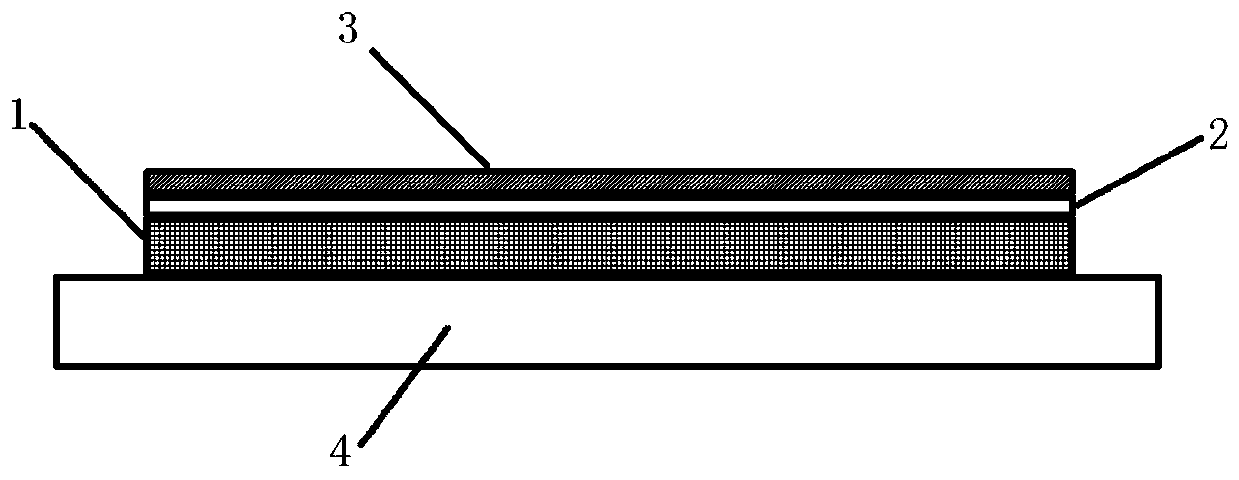

[0031] refer to figure 1 , indicating a secondary electron emission film structure of magnesium oxide doped with gold and aluminum oxide. The secondary electron emission film is composed of three layers of films, that is, the gold-doped magnesium oxide film layer 1 at the bottom layer, the aluminum oxide-doped magnesium oxide film layer 2 at the middle layer and the pure magnesium oxide film layer 3 at the top layer . The three-layer films of the magnesium oxide secondary electron emission film doped with gold and aluminum oxide are successively deposited on the metal substrate 4 by the sputtering method, including the following steps:

[0032]First, a gold-doped magnesium oxide film layer 1 is deposited on a stainless steel substrate 4 by radio frequency sputtering magnesium target and DC sputtering gold target. During the deposition process, the temperature of the stainless steel substrate is kept at 350°C, and Argon and oxygen, the flow ratio of argon to oxygen is 5:1, th...

Embodiment 2

[0034] refer to figure 1 , indicating a secondary electron emission film structure of magnesium oxide doped with gold and aluminum oxide. The secondary electron emission film is composed of three layers of films, that is, the gold-doped magnesium oxide film layer 1 at the bottom layer, the aluminum oxide-doped magnesium oxide film layer 2 at the middle layer and the pure magnesium oxide film layer 3 at the top layer . The three-layer films of the magnesium oxide secondary electron emission film doped with gold and aluminum oxide are successively deposited on the metal substrate 4 by the sputtering method, including the following steps:

[0035] Firstly, a gold-doped magnesium oxide film layer 1 is deposited on a stainless steel substrate 4 by means of radio frequency sputtering magnesium oxide target and direct current sputtering gold target. Introduce argon and oxygen, the flow ratio of argon and oxygen is 15:1, the total pressure in the coating chamber is 0.2Pa, the thickn...

Embodiment 3

[0037] refer to figure 1 , indicating a secondary electron emission film structure of magnesium oxide doped with platinum and aluminum oxide. The secondary electron emission film is composed of three layers, that is, the platinum-doped magnesium oxide film layer 1 in the bottom layer, the aluminum oxide-doped magnesium oxide film layer 2 in the middle layer and the pure magnesium oxide film layer 3 in the top layer . The three-layer films of the magnesium oxide secondary electron emission film doped with platinum and aluminum oxide are successively deposited on the metal substrate 4 by sputtering, including the following steps:

[0038] Firstly, a platinum-doped magnesium oxide film 1 is deposited on a stainless steel substrate 4 by means of radio frequency sputtering magnesium target and direct current sputtering platinum target. During the deposition process, the temperature of the stainless steel substrate is kept at 400°C, Enter argon and oxygen, the flow ratio of argon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com