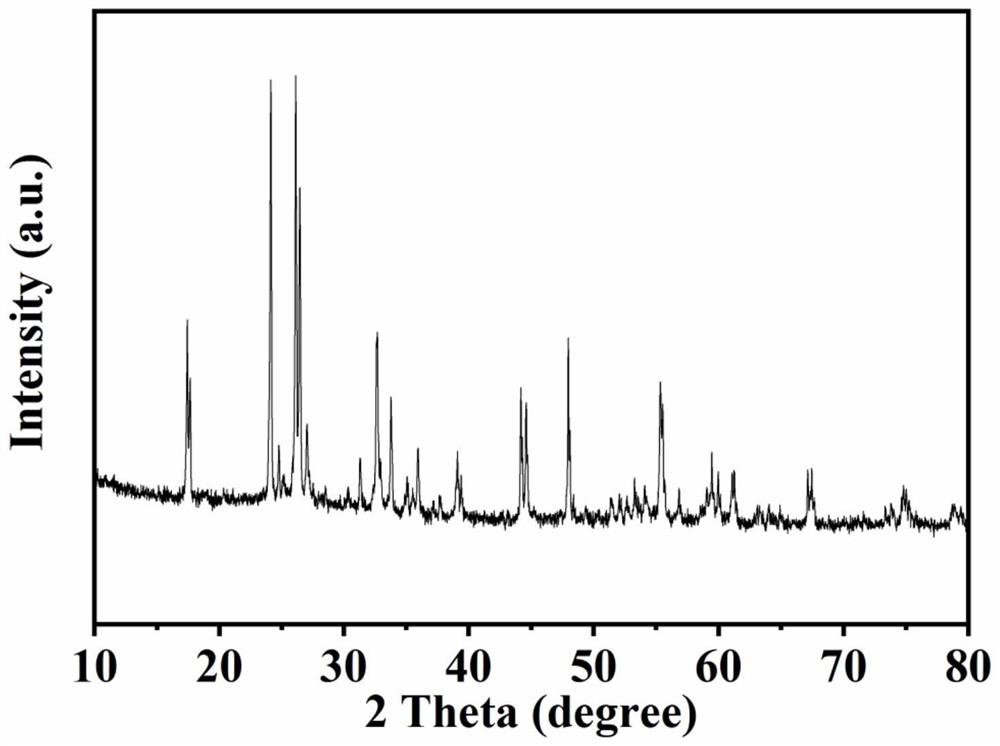

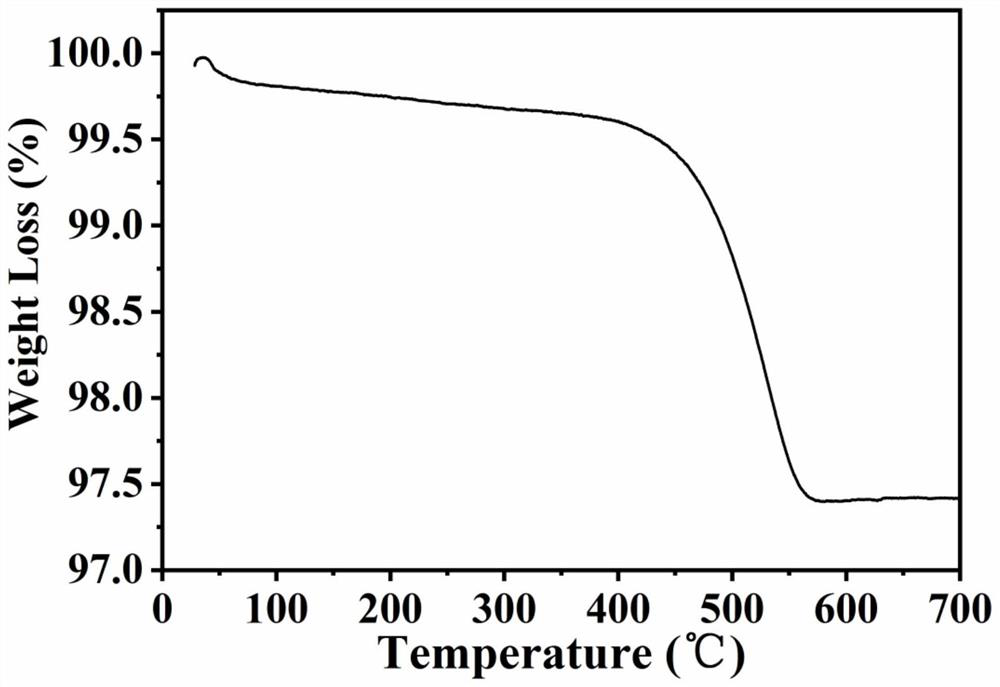

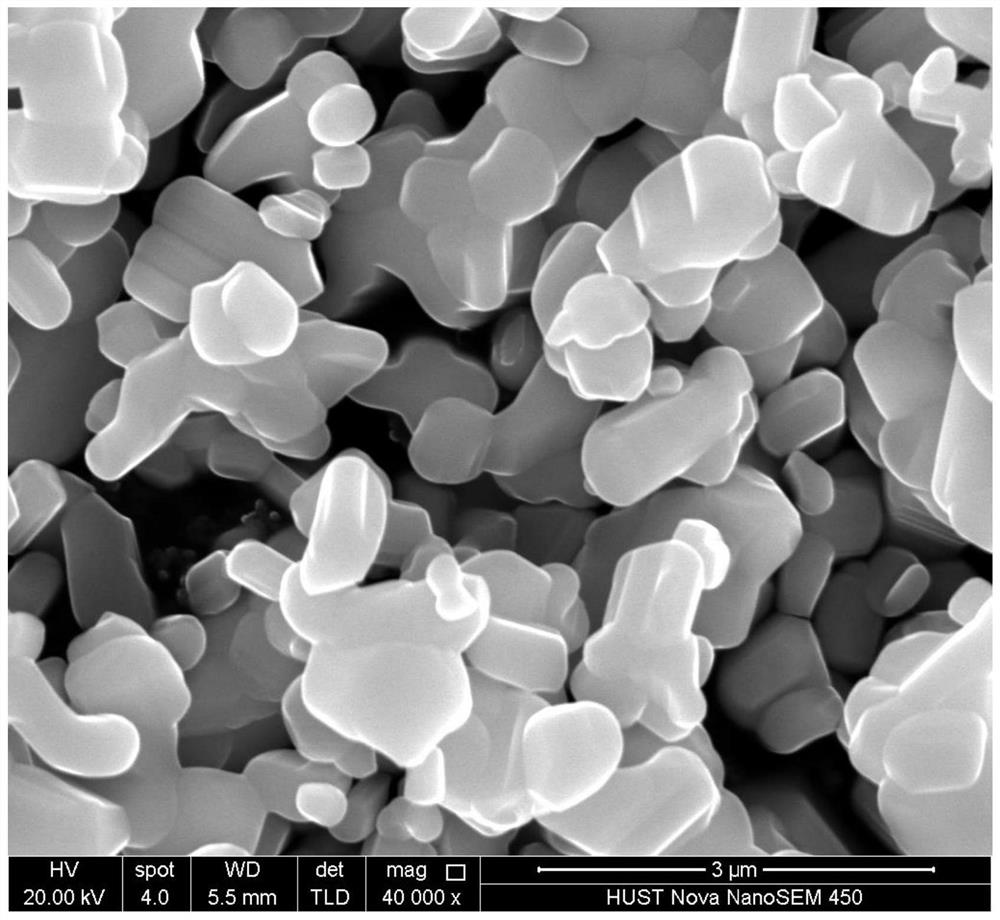

In-situ carbon-coated titanium niobate composite material, and preparation method and application thereof

A composite material, carbon coating technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problem of shortening the migration distance of carriers inside the primary particle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An in-situ carbon-coated titanium niobate composite material is prepared by the following method:

[0036] (1) Weigh 2.11g Nb(OC 2 h 5 ) 5 Dissolve in 40mL absolute ethanol, stir well, then weigh 1.13g Ti(OC 4 h 9 ) 4 Add to the above solution and stir vigorously for 1 hour to obtain a mixed solution;

[0037] (2) Then add 0.1 g of ascorbic acid and stir rapidly for 2 hours, and vacuum-dry the obtained suspension at 150° C. for 12 hours to obtain a powder mixture;

[0038] (3) Place the obtained powder mixture in a tube furnace, feed nitrogen gas, raise the temperature at 5°C / min to 500°C and keep it warm for 10 hours, then naturally cool down to normal temperature to obtain the first product;

[0039] (4) Place the primary product in a muffle furnace, raise the temperature at 5°C / min to 350°C for 1 hour in an air atmosphere, and then cool down naturally to room temperature to obtain the target product TiNb 2 o7 @C.

Embodiment 2

[0041] An in-situ carbon-coated titanium niobate composite material is prepared by the following method:

[0042] (1) Weigh 5.4g NbCl 5 Dissolve in 80mL absolute ethanol, stir well, then weigh 2.84g Ti(OC 3 h 7 ) 4 Add to the above solution and stir vigorously for 2 hours to obtain a mixed solution;

[0043] (2) Add 0.4 g of sucrose and stir rapidly for 3 hours, and freeze-dry the obtained suspension for 24 hours to obtain a powder mixture;

[0044] (3) Put the powder mixture in a tube furnace, feed nitrogen gas, raise the temperature at 5°C / min to 800°C and keep it warm for 5 hours, then cool down to normal temperature naturally to obtain the first product;

[0045] (4) Put the primary product in a muffle furnace, under a pure oxygen atmosphere, heat up to 400°C at 3°C / min and keep it for 0.5 hours, then cool down naturally to room temperature to obtain the target product TiNb 2 o 7 @C.

Embodiment 3

[0047] An in-situ carbon-coated titanium niobate composite material is prepared by the following method:

[0048] (1) Weigh 7.986g TiO 2 Disperse in 1000mL water, stir well, then weigh 318.972g Nb 2 o 5 Add to the above mixture and stir vigorously for 1 hour to obtain the target mixture;

[0049] (2) Add 31.897g of glucose and stir rapidly for 2 hours, and the obtained suspension is spray-dried to obtain a powder mixture;

[0050] (3) Place the obtained powder mixture in a tube furnace, feed nitrogen gas, raise the temperature at 10°C / min to 1300°C and keep it warm for 10 hours, then cool down to normal temperature naturally to obtain the first product;

[0051] (4) Place the primary product in a muffle furnace, raise the temperature at 20°C / min to 500°C for 0.2 hours in an air atmosphere, and cool down naturally to room temperature to obtain the target product TiNb 24 o 62 @C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com