Special coated controlled-release insecticide for peanuts and preparation method thereof

A special package and insecticide technology, applied in the direction of insecticides, botany equipment and methods, biocides, etc., can solve the problems affecting the quality and safety of peanuts, low effective utilization rate of pesticides, short duration of drug effects, etc. , to achieve the effect of preventing non-point source pollution, reducing the amount of pesticides, and having a good market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

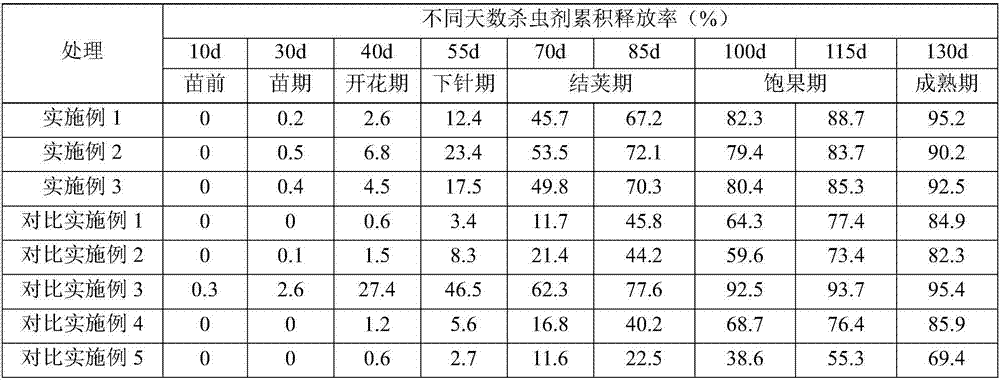

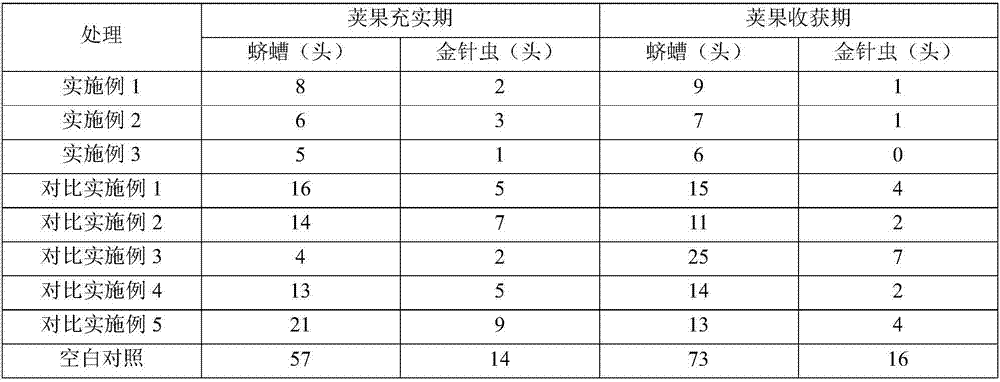

Embodiment 1

[0031] A special coating controlled-release insecticide for peanuts is characterized in that it contains a three-layer structure, wherein

[0032] The raw material composition of the inner layer is 0.1 parts of phoxim, 1 part of imidacloprid, 1.5 parts of chlorpyrifos, 5 parts of chlorantraniliprole, 20 parts of wheat bran, 90 parts of humic acid, and 20 parts of adhesive;

[0033] The raw material composition of the middle layer is 0.5 parts of phoxim, 1 part of imidacloprid, 5 parts of chlorpyrifos, 2.5 parts of chlorantraniliprole, 90 parts of humic acid, and 20 parts of urea-formaldehyde powder;

[0034] The raw materials of the outer layer consist of 60 parts of urea-formaldehyde powder and 30 parts of fermented excrement of livestock and poultry;

[0035] The livestock and poultry fermented manure is obtained through the following steps:

[0036] According to the weight ratio, mix 2-5 parts of chicken manure, 2-5 parts of sheep manure, and 2-5 parts of cow manure to obt...

Embodiment 2

[0043] A special coating controlled-release insecticide for peanuts is characterized in that it contains a three-layer structure, wherein

[0044] The raw material composition of the inner layer is 0.3 parts of phoxim, 0.5 parts of imidacloprid, 3.5 parts of chlorpyrifos, 2.5 parts of chlorantraniliprole, 40 parts of wheat bran, 40 parts of humic acid, and 50 parts of adhesive;

[0045]The raw material composition of the middle layer is 0.2 parts of phoxim, 2 parts of imidacloprid, 2.5 parts of chlorpyrifos, 5 parts of chlorantraniliprole, 40 parts of humic acid, and 30 parts of urea-formaldehyde powder;

[0046] The raw materials of the outer layer consist of 40 parts of urea-formaldehyde powder and 40 parts of fermented excrement of livestock and poultry;

[0047] The livestock and poultry fermented manure is obtained through the following steps:

[0048] According to the weight ratio, mix 2-5 parts of chicken manure, 2-5 parts of sheep manure, and 2-5 parts of cow manure t...

Embodiment 3

[0055] A special coating controlled-release insecticide for peanuts is characterized in that it contains a three-layer structure, wherein

[0056] The raw material composition of the inner layer is 0.2 parts of phoxim, 0.7 parts of imidacloprid, 2.5 parts of chlorpyrifos, 3.5 parts of chlorantraniliprole, 30 parts of wheat bran, 65 parts of humic acid, and 30 parts of adhesive;

[0057] The raw material composition of the middle layer is 0.4 parts of phoxim, 1.5 parts of imidacloprid, 4 parts of chlorpyrifos, 3.5 parts of chlorantraniliprole, 70 parts of humic acid, and 25 parts of urea-formaldehyde powder;

[0058] The raw materials of the outer layer consist of 50 parts of urea-formaldehyde powder and 35 parts of fermented excrement of livestock and poultry;

[0059] The livestock and poultry fermented manure is obtained through the following steps:

[0060] According to the weight ratio, mix 2-5 parts of chicken manure, 2-5 parts of sheep manure, and 2-5 parts of cow manur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com