Preparation method of catalyst with modified binderless ZSM-11 molecular sieves and application

A ZSM-11, binder-free technology, applied to molecular sieve catalysts, including molecular sieve catalysts, catalysts, etc., can solve the problems of strength reduction, acid content reduction, etc., and achieve the effect of improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

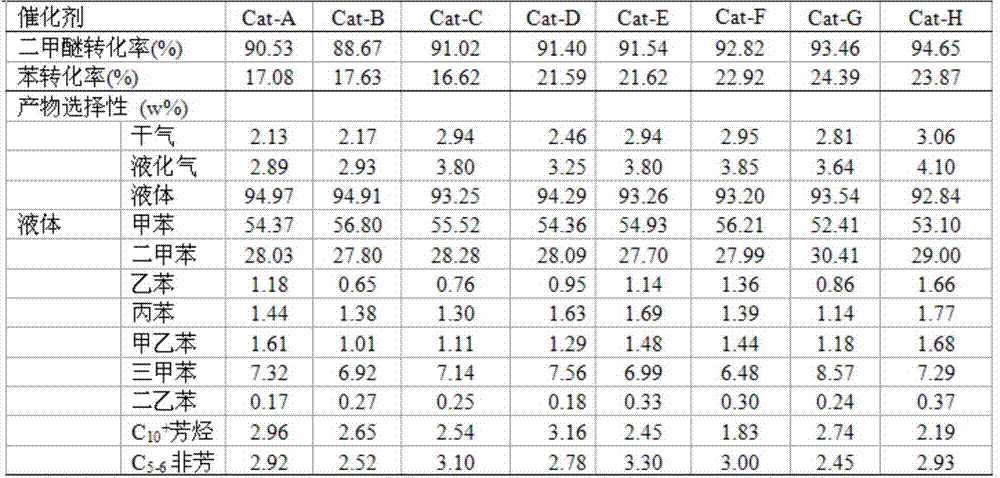

Embodiment 1

[0027] Binder-free product B in Comparative Example 1 was washed with distilled water, dried, calcined at 550°C for 4 hours, then exchanged with 0.8mol / L ammonium nitrate solution for 3 times at 80°C, washed twice with water, dried at 120°C, and calcined at 540°C 3h, get H-type molecular sieve, and then routinely impregnate and load rare earth and aluminum, use lanthanum nitrate and aluminum nitrate solution, dry at 85°C for 2h, and roast at 550°C for 4h, the loading capacity of the obtained catalyst La and Al is 2.5wt% and 4.0wt%, followed by steam treatment at 550°C for 2h, the obtained catalyst is designated as Cat-D.

Embodiment 2

[0029] Binder-free product B in Comparative Example 1 was washed with distilled water, dried, and roasted at 550°C for 4 hours, then exchanged with 0.6mol / L ammonium nitrate solution at 70°C for 3 times, washed twice with water, dried at 120°C, and dried at 500°C. Calcined at ℃ for 5 hours to obtain H-type molecular sieves, and then routinely impregnated and supported rare earth and aluminum, using lanthanum nitrate and aluminum nitrate solutions, dried at 90℃ for 1.5h, and calcined at 500℃ for 5h, the loading capacity of the obtained catalysts La and Al were 0.3 wt% and 1.2wt%, followed by steam treatment at 580°C for 3h, the obtained catalyst is designated as Cat-E.

Embodiment 3

[0031] Binder-free product B in Comparative Example 1 was washed with distilled water, dried, and roasted at 550°C for 4 hours, then exchanged three times with 0.7mol / L ammonium nitrate solution at 60°C, washed twice with water, dried at 120°C, and dried at 550°C. Calcined at ℃ for 4 hours to obtain H-type molecular sieves, and then routinely impregnated and supported rare earth and aluminum, using cerium nitrate and aluminum phosphate solutions, dried at 95℃ for 3 hours, and calcined at 580℃ for 5 hours, the loading capacity of the obtained catalysts Ce and Al were 5.3wt % and 9.2wt%, followed by steam treatment at 630°C for 7h, the resulting catalyst is designated as Cat-F.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com