Method and device for extracting lithium from salt lake brine with high magnesium-lithium ratio

A technology of salt lake brine and high ratio of magnesium to lithium, applied in lithium halide and other directions, can solve the problems of consumption of fresh water, low quality of lithium carbonate products, and large dissolution loss of adsorbents, and achieve the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

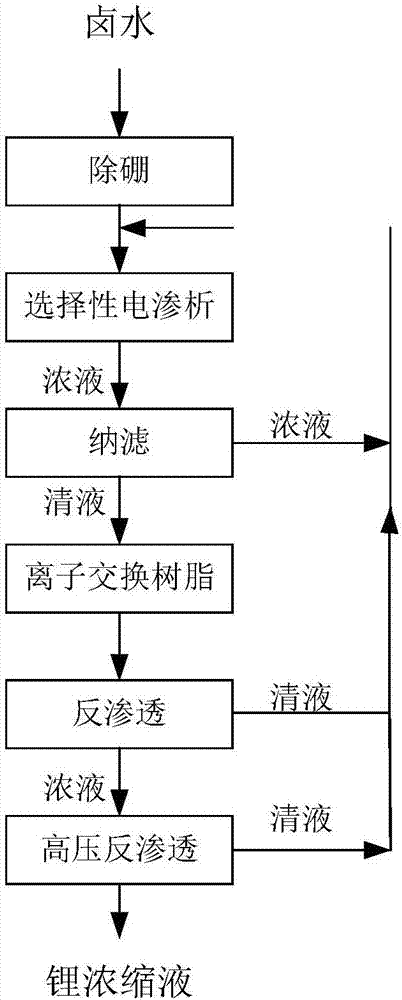

[0066] (1) After the brine is concentrated by natural evaporation, the Mg 2+ The concentration is 123.4g / L, Li + The concentration is 2.40g / L, Na + The concentration is 2.20g / L, B + The concentration is 1.60g / L, SO 4 2- The concentration is 32.6g / L, and the COD is 187.7mg / L. After adding sulfuric acid to acidify, boron is extracted to obtain boron-removing brine. B in the brine + The concentration is 50mg / L;

[0067] (2) Mix the boron-removing brine with the concentrated water produced by the nanofiltration process in the later stage, and then enter the fresh water side of the electrodialysis equipment with ion selection function, and mix the pure water with the clear liquid produced by the reverse osmosis and high-pressure reverse osmosis process As the starting solution of concentrated water, under the action of electric field force, monovalent ions pass through the ion selective membrane from the fresh water side to the concentrated water side, while most of the divale...

Embodiment 2

[0073] (1) After the brine is concentrated by natural evaporation, the Mg 2+ The concentration is 112.5g / L, Li + The concentration is 3.0g / L, Na + The concentration is 2.8g / L, B + The concentration is 2.0g / L, SO 4 2- The concentration is 28.4g / L, and the COD is 189.9mg / L. After adding sulfuric acid to acidify, boron is extracted to obtain boron-removing brine. B in the brine + The concentration is 48mg / L;

[0074] (2) Mix the boron-removing brine with the concentrated water produced by the nanofiltration process in the later stage, and then enter the fresh water side of the electrodialysis equipment with ion selection function, and mix the pure water with the clear liquid produced by the reverse osmosis and high-pressure reverse osmosis process As the starting solution of concentrated water, under the action of electric field force, monovalent ions pass through the ion selective membrane from the fresh water side to the concentrated water side, while most of the divalent ...

Embodiment 3

[0080] (1) After the brine is concentrated by natural evaporation, the Mg 2+ The concentration is 132.1g / L, Li+ The concentration is 2.3g / L, Na + The concentration is 2.2g / L, B + The concentration is 2.3g / L, SO 4 2- The concentration is 33.1g / L, and the COD is 190.9mg / L. Add sulfuric acid and acidify to extract boron to obtain boron-removing brine. B in the brine + The concentration is 48mg / L;

[0081] (2) Mix the boron-removing brine with the concentrated water produced by the nanofiltration process in the later stage, and then enter the fresh water side of the electrodialysis equipment with ion selection function, and mix the pure water with the clear liquid produced by the reverse osmosis and high-pressure reverse osmosis process As the starting solution of concentrated water, under the action of electric field force, monovalent ions pass through the ion selective membrane from the fresh water side to the concentrated water side, while most of the divalent ions are trap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com