3D printed composite scaffold as well as preparation method and application thereof

A 3D printing and binary composite technology, applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve the problems of affecting osteogenic performance, hindering host osseointegration, lack of promotion of bone tissue regeneration, etc., to improve the degradation rate, Improve hydrophilic performance and good in vitro biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

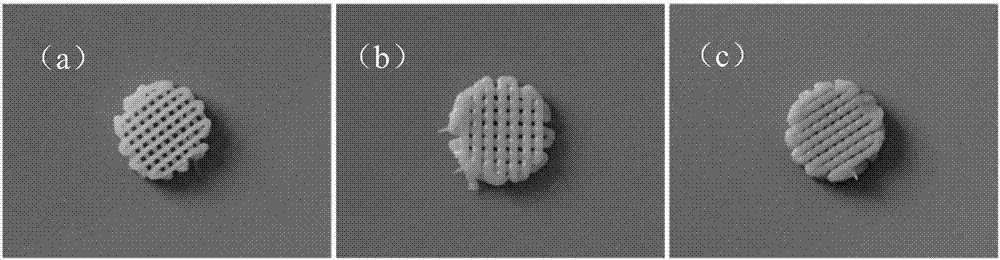

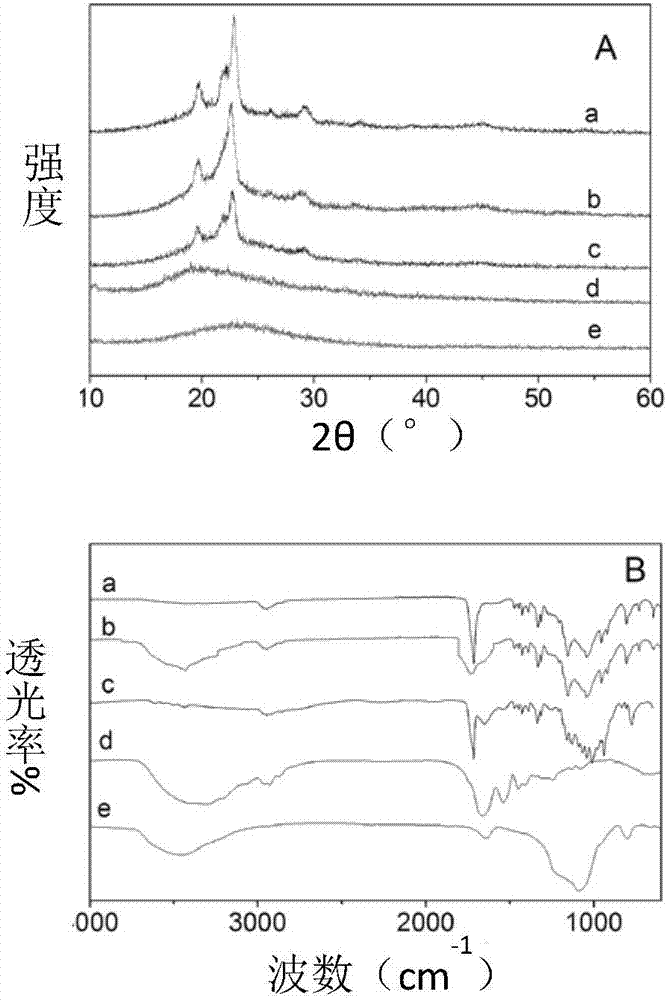

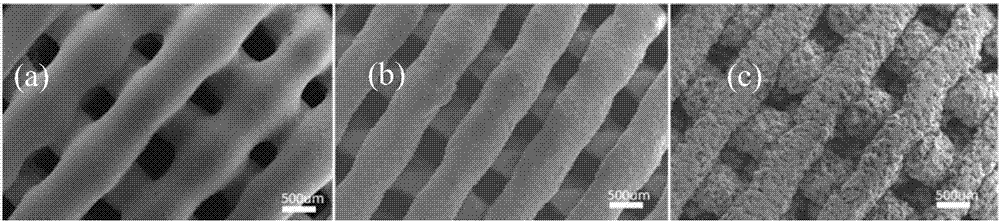

[0083] Example 1 Preparation of Mesoporous Magnesium Silicate / Polybutylene Succinate Binary Composite Scaffold (S2)

[0084] (1) Preparation of mesoporous magnesium silicate (m-MS)

[0085] The m-MS of this embodiment is prepared by the following method:

[0086]Put a mixed solution of 30mL deionized water and 120mL 2.0M dilute hydrochloric acid in a 50°C water bath. Then, accurately weigh 4.0 g of P123, add it into the above mixed solution, and stir for 30 minutes until clear. Subsequently, 4.8 g of magnesium nitrate hexahydrate and 8.5 g of ethyl orthosilicate were successively weighed and added to the above clear solution, and stirred for 5 hours. After standing still, filter with suction, wash with deionized water, and filter with suction again. After repeating 3 times, place in a 60°C electric blast drying oven to obtain a white powder. The powder was put into a stainless steel mold, and a disc sample (Φ12×2mm) was prepared under a pressure of 2MPa using a tablet press...

Embodiment 2

[0089] Example 2 Preparation of Mesoporous Magnesium Silicate / Polybutylene Succinate / Gliadin Ternary Composite Scaffold (S3)

[0090] (1) Preparation of mesoporous magnesium silicate (m-MS)

[0091] The m-MS of this embodiment is prepared by the following method:

[0092] Put a mixed solution of 30mL deionized water and 120mL 2.0M dilute hydrochloric acid in a 50°C water bath. Then, accurately weigh 4.0 g of P123, add it into the above mixed solution, and stir for 30 minutes until clear. Subsequently, 4.8 g of magnesium nitrate hexahydrate and 8.5 g of ethyl orthosilicate were successively weighed and added to the above clear solution, and stirred for 5 hours. After standing still, filter with suction, wash with deionized water, and filter with suction again. After repeating 3 times, place in a 60°C electric blast drying oven to obtain a white powder. The powder was put into a stainless steel mold, and a disc sample (Φ12×2mm) was prepared under a pressure of 2MPa using a ta...

Embodiment 3

[0095] Example 3 Preparation of Mesoporous Magnesium Silicate / Polybutylene Succinate Binary Composite Scaffold (S4)

[0096] (1) Preparation of mesoporous magnesium silicate (m-MS)

[0097] The m-MS of this embodiment is prepared by the following method:

[0098] Put a mixed solution of 30mL deionized water and 120mL 2.0M dilute hydrochloric acid in a 50°C water bath. Then, accurately weigh 4.0 g of P123, add it into the above mixed solution, and stir for 30 minutes until clear. Subsequently, 4.8 g of magnesium nitrate hexahydrate and 8.5 g of ethyl orthosilicate were successively weighed and added to the above clear solution, and stirred for 5 hours. After standing still, filter with suction, wash with deionized water, and filter with suction again. After repeating 3 times, place in a 60°C electric blast drying oven to obtain a white powder. The powder was put into a stainless steel mold, and a disc sample (Φ12×2mm) was prepared under a pressure of 2MPa using a tablet pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com