Advanced oxidation equipment and sewage treatment system

A sewage treatment system, advanced oxidation technology, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, anaerobic digestion treatment, etc. To achieve the effect of strong anti-pollution ability, low operating cost and long anode life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described below in conjunction with the accompanying drawings and specific implementation.

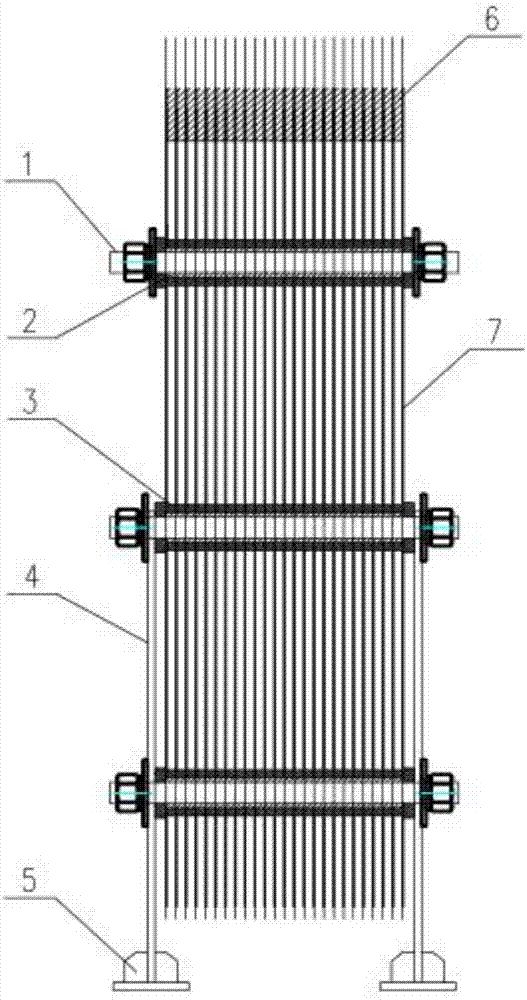

[0027] Such as figure 1 As shown, an advanced oxidation equipment includes a pull rod 1, an insulating sleeve 2, an insulating gasket 3, a first connector 4, a fixed bottom corner 5, a power connector 6, and an electrode plate 7, wherein the pull rod 1 is used for fixed connection The electrode plate, the insulating sleeve 2 is used to set the pull rod 1, the insulating electrode plate 7 is used to prevent short circuit, the insulating gasket 3 is used to limit the distance between the electrode plates, and is installed on the insulating sleeve 2, and the connecting piece 6 is used for the support device, and the pull rod 1 Connection and fixation, fixed bottom angle 5, welded on the first connecting piece 4, so that the device can be fixed and placed stably, the power supply connecting piece 6, welded between the electrode plates of the same polari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com