Preparation process of low-sodium corundum

A preparation process, corundum technology, applied in the field of low-sodium corundum preparation process, can solve problems such as low efficiency, heavy environmental pollution, time-consuming and labor-intensive, etc., and achieve the effects of improving production efficiency, eliminating pollution, and increasing melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

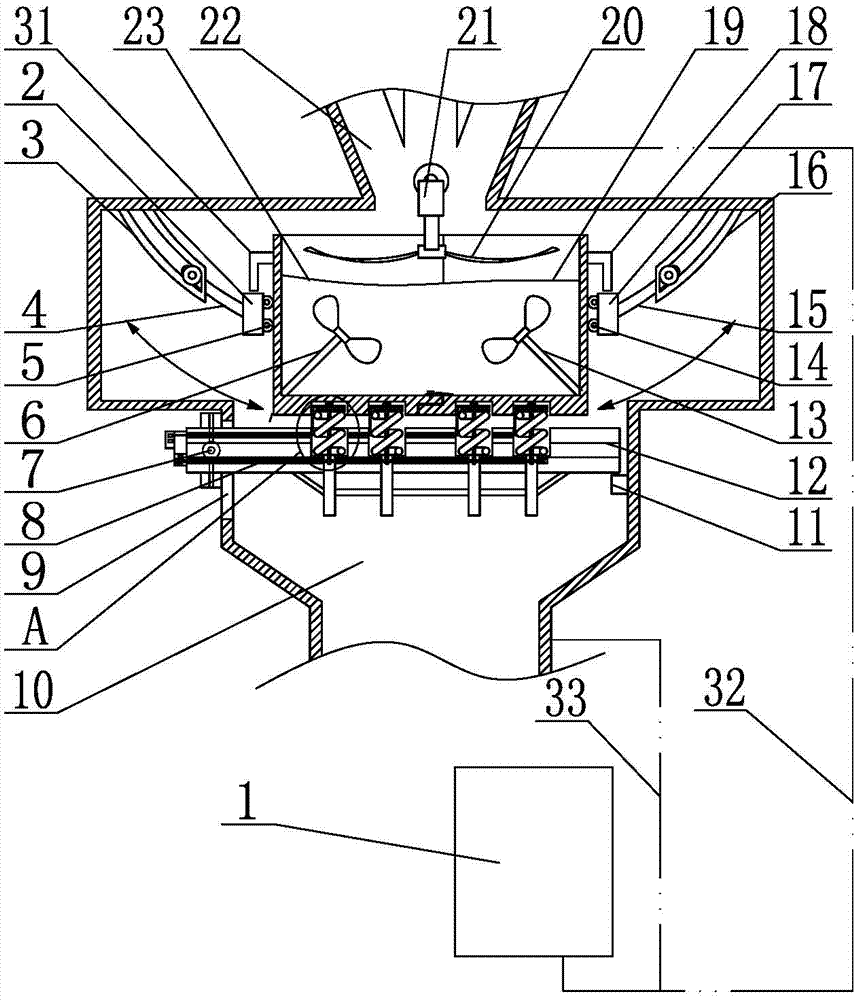

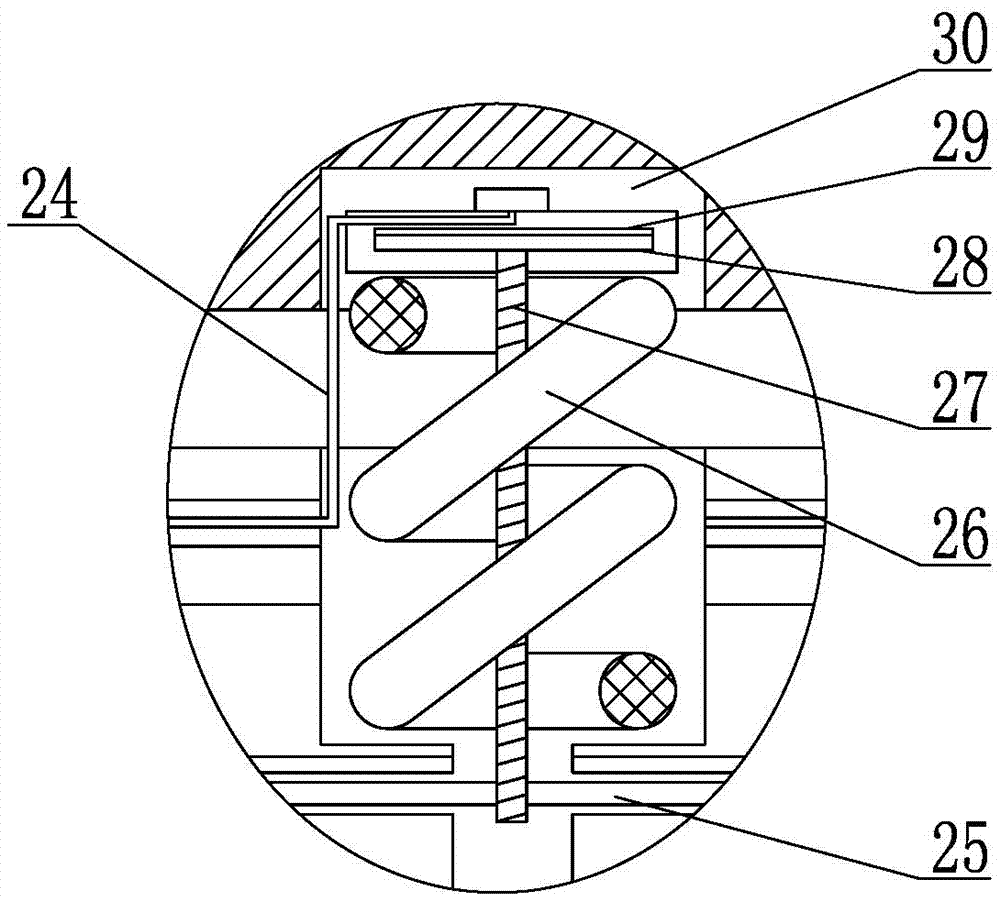

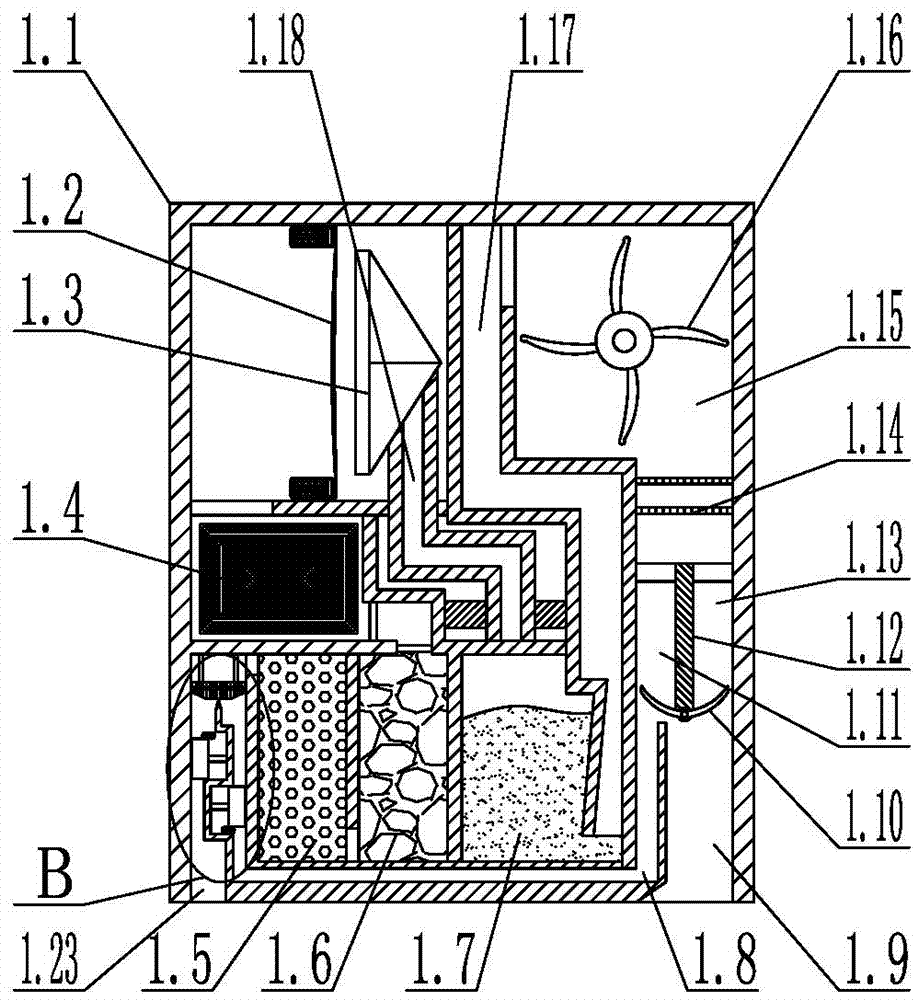

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0053] A preparation process of low-sodium corundum, the required raw materials include the following components in terms of mass:

[0054] Industrial alumina 100-105 parts,

[0055] 5-10 parts of acetic acid or boric acid,

[0056] 10-15 parts of ammonium chloride,

[0057] Aluminum oxide 2-10 parts.

[0058] Concrete embodiment sees the following table:

[0059]

[0060] The chemical composition of described industrial aluminum oxide is as follows:

[0061] Silicon oxide 0.01-0.02%,

[0062] Iron oxide 0.015-0.025%,

[0063] Potassium oxide 0.015-0.02%,

[0064] Sodium oxide 0.1-0.2%,

[0065] Aluminum Oxide 98-99%,

[0066] The rest is water.

[0067] The preparation technology of low-sodium corundum comprises the following steps:

[0068] (1) Weigh all the raw materials according to the ratio and add them to the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com