Stable thermally reversible discoloration core-shell polymer emulsion with hysteresis effect and preparation method thereof

A technology of polymer emulsion and hysteresis effect, applied in the field of emulsion polymerization, can solve the problems of loss of discoloration ability, poor reversibility and stability, application limitations, etc., and achieve broad application range, good thermal stability and storage stability, and raw material utilization high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

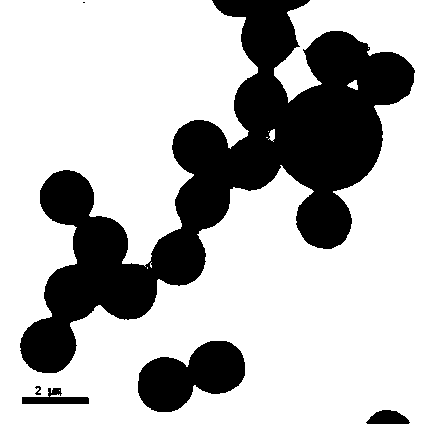

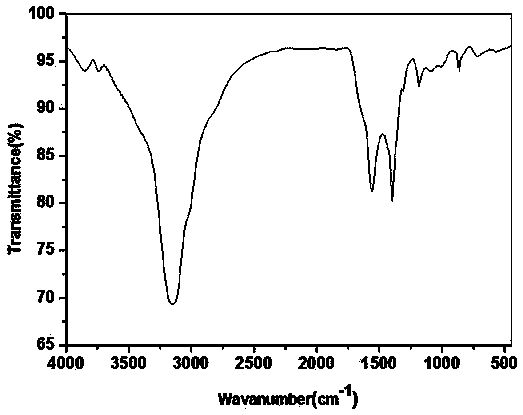

[0032] The stable thermally reversible discoloration core-shell polymer emulsion with hysteresis effect of the present embodiment is a mixture of crystal violet lactone, bisphenol A and capric triglyceride as the core, and the capric glycerin The triester is the reaction medium that determines the temperature at which the color reaction and hysteresis effect of crystal violet lactone and bisphenol A occur. The core-shell structure polymer with maleic anhydride, styrene and methyl methacrylate as the shell is water-based In the emulsion, the inner core is dispersed in the aqueous emulsion of the core-shell structure polymer by an emulsifier, and the mass ratio of crystal violet lactone, bisphenol A and capric triglyceride is 1:2:40.

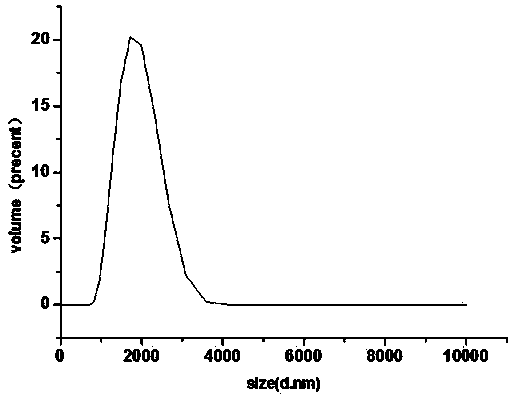

[0033] The solid content of the core-shell polymer emulsion described in this example is 30%, the particle size distribution range is 825-3580nm, and the average particle size is 1852nm, see figure 2 .

[0034] The preparation method of the stab...

Embodiment 2

[0048] The stable thermally reversible discoloration core-shell polymer emulsion with hysteresis effect of this embodiment is based on dienyl halo-2-benzo[C]furanone, stearic acid terephthalic acid and The mixture of capric triglycerides is the inner core, and the capric triglycerides determine the color reaction and hysteresis effect of dienyl halo-2-benzo[C]furanone and stearic acid terephthalic acid The temperature of the reaction medium, the polymer of maleic anhydride, styrene and methyl methacrylate is the core-shell structure polymer aqueous emulsion of the shell, and the inner core is dispersed in the core-shell structure polymer water-based emulsion by an emulsifier. In the emulsion, the mass ratio of the dienyl halo-2-benzo[C]furanone, stearic acid terephthalic acid and capric triglyceride is 1:1:1.

[0049] The core-shell polymer emulsion described in this example has a solid content of 20%, a particle size distribution range of 825-3580 nm, and an average particle ...

Embodiment 3

[0062] The stable thermally reversible discoloration core-shell polymer emulsion with hysteresis effect of this embodiment is based on a mixture of thermosensitive green, α-naphthol and ethyl caprate as the core, and the ethyl caprate It is the reaction medium that determines the temperature of thermosensitive green and α-naphthol color reaction and hysteresis effect. It is a core-shell polymer aqueous emulsion with a polymer of maleic anhydride, styrene and methyl methacrylate as the shell. The inner core is dispersed in the aqueous emulsion of the core-shell structure polymer by an emulsifier, and the mass ratio of the thermosensitive green, α-naphthol and ethyl caprate is 1:4:50.

[0063] The core-shell polymer emulsion described in this example has a solid content of 50%, a particle size distribution range of 825-3580 nm, and an average particle size of 1852 nm.

[0064] The preparation method of the stable thermally reversible discoloration core-shell polymer emulsion wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com