Modified polylactic acid preparation method and modified polylactic acid preparation device

A preparation device and technology of polylactic acid, applied in the field of preparation method of modified polylactic acid and its preparation device, can solve the problem of poor flexibility and impact resistance of polylactic acid, insignificant toughening effect of polylactic acid, and insufficient fluency of the preparation process and other problems, to achieve the effect of increasing hydrophilicity, increasing sustained release effect, and increasing fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

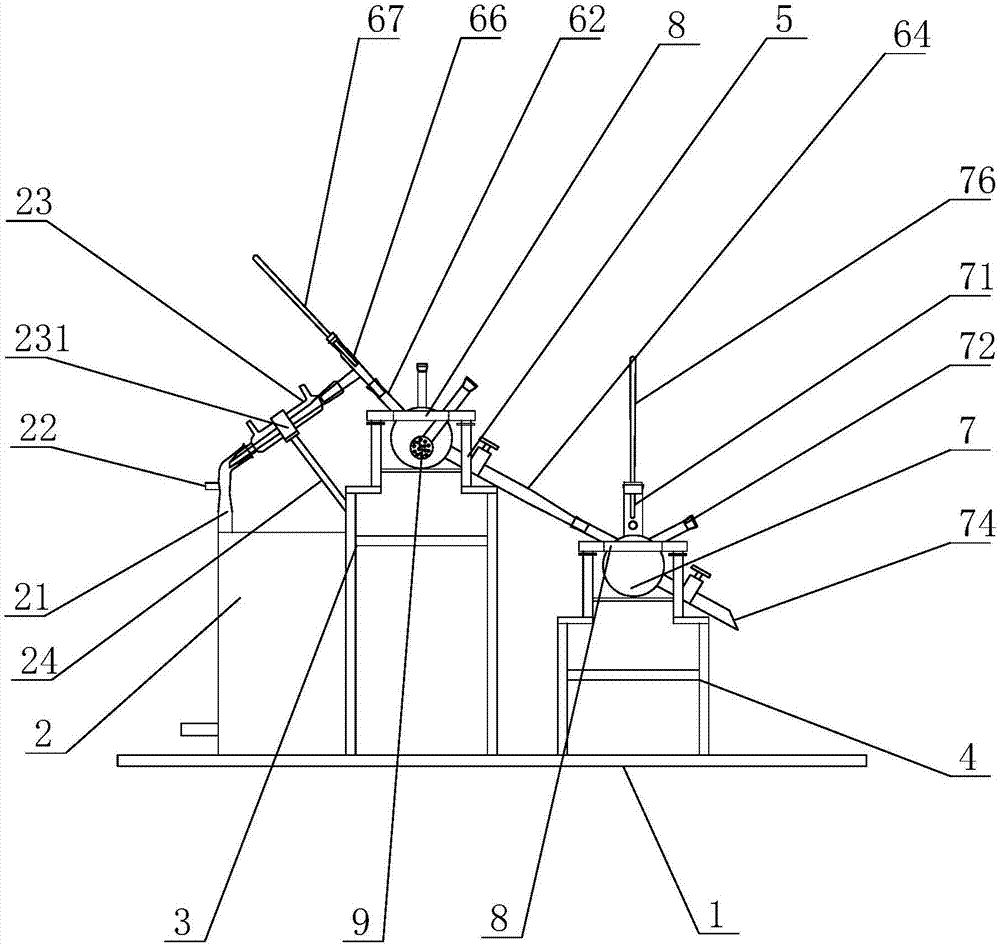

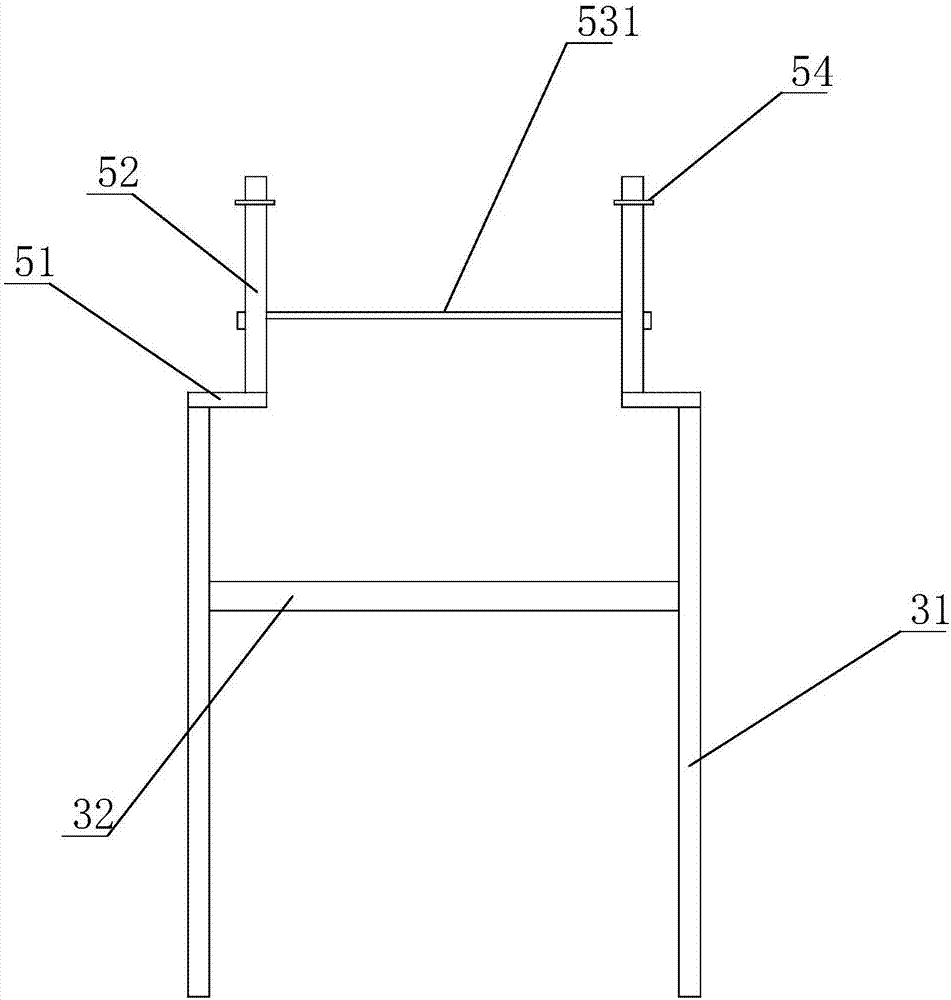

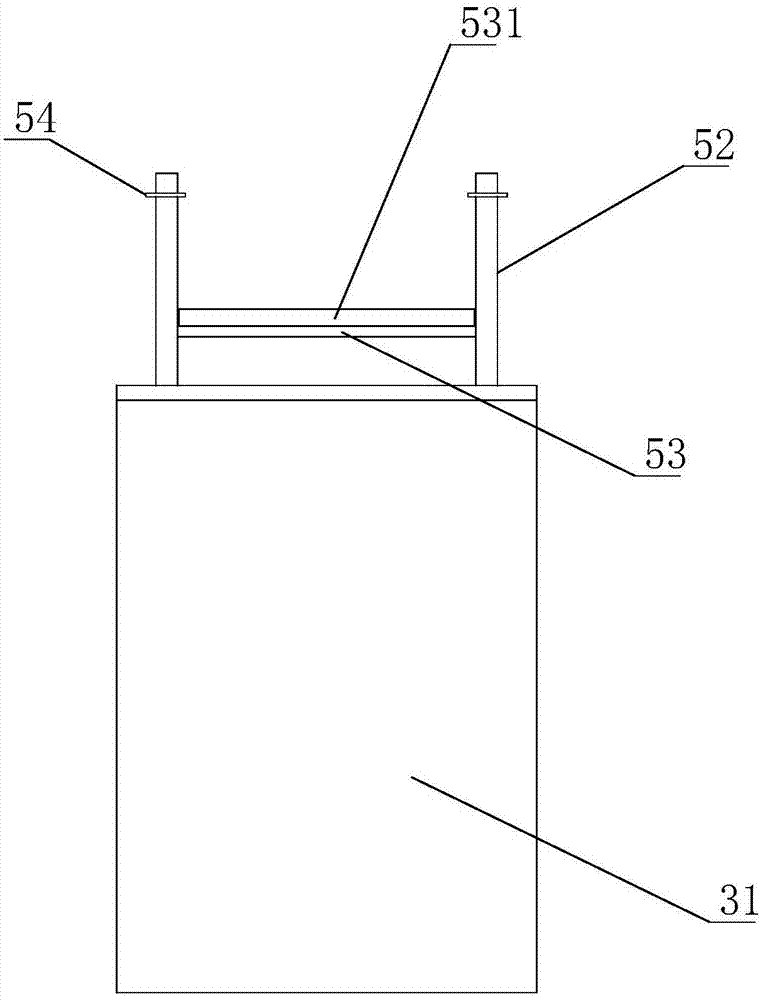

Image

Examples

Embodiment 1

[0045] Embodiment 1: the preparation method of modified polylactic acid,

[0046] Step 1: Take an appropriate amount of L-lactic acid and put it in container I. After vacuumizing container I, distill at 25°C for 1 hour, then put molecular sieves into container I for later use. , adding molecular sieves to purify the L-lactic acid.

[0047] Step 2: Add the dehydrated L-lactic acid and 1,4-butanediol to container II in sequence, the mass ratio of L-lactic acid and 1,4-butanediol is n L-乳酸 :n 1,4-丁二醇 =40:1, the container II is heated to 70°C, and then stannous chloride is added, the mass ratio of L-lactic acid to 1,4-butanediol is n L-乳酸 :n 氯化亚锡 =100:1 Heating to 110°C for 30 minutes, using stannous chloride as a catalyst, and polymerizing L-lactic acid under the action of 1,4-butanediol.

[0048] Step 3: Vacuumize the container II, and then gradually increase the temperature in the container II at a heating rate of 7°C / 30min until the temperature reaches 160°C, continue the ...

Embodiment 2

[0056] Embodiment 2: the preparation method of modified polylactic acid,

[0057] Step 1: Take an appropriate amount of L-lactic acid and place it in container I, vacuumize container I, distill at 30°C for 1 hour, and then put molecular sieves into container I for later use;

[0058] Step 2: Pass N into container II 2 , and continue for a period of time to get rid of the original gas in the container 1;

[0059] Step 3: Add L-lactic acid and 1,4-butanediol after water removal to container II in sequence, the mass ratio of L-lactic acid and 1,4-butanediol is n L-乳酸 :n 1,4-丁二醇 =60:1, heat the container II to 75°C, then add stannous chloride, the mass ratio of L-lactic acid to 1,4-butanediol is n L-乳酸 :n 氯化亚锡 =150:1 heated to 120°C for 45 minutes;

[0060] Step 4: Vacuumize the container II, then gradually increase the temperature in the container II at a heating rate of 8°C / 30min until the temperature reaches 170°C, continue the reaction for 8h, stop heating, remove the vac...

Embodiment 3

[0068] Embodiment 3: the preparation method of modified polylactic acid,

[0069] Step 1: Take an appropriate amount of L-lactic acid and place it in container I, vacuumize container I, distill at 40°C for 1 hour, and then put molecular sieves into container I for later use;

[0070] Step 2: Add the dehydrated L-lactic acid and 1,4-butanediol to container II in sequence, the mass ratio of L-lactic acid and 1,4-butanediol is n L-乳酸 :n 1,4-丁二醇 =80:1, the container II is heated to 80°C, and then stannous chloride is added, the mass ratio of L-lactic acid to 1,4-butanediol is n L-乳酸 :n 氯化亚锡 =250:1 heated to 130°C for 70 minutes;

[0071] Step 3: Vacuumize container II, then gradually increase the temperature in container II at a heating rate of 10°C / 30min until the temperature reaches 180°C, continue the reaction for 15 hours, stop heating, remove the vacuum, and obtain product A;

[0072] Step 4: Add an appropriate amount of the product A synthesized in step 4 into the three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com