Heat dissipation coating based on graphene and preparation method thereof

A technology of heat-dissipating coatings and graphene, applied in anti-corrosion coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc., can solve the problem of low radiation heat dissipation, improve thermal conductivity and thermal radiation rate, and solve the problem of radiation The effect of low heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

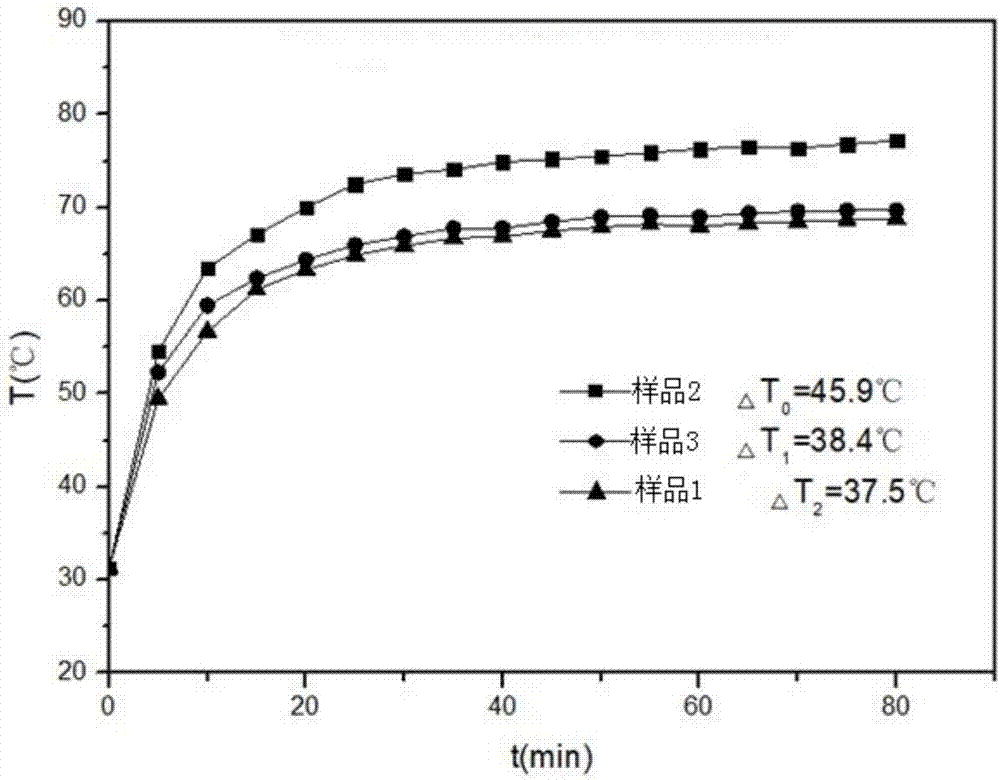

Image

Examples

Embodiment 1

[0042] Embodiment 1: the heat-dissipating coating based on graphene powder provided by the present embodiment is mainly composed of A component and B, and the mass ratio of A component and B component is 8:1;

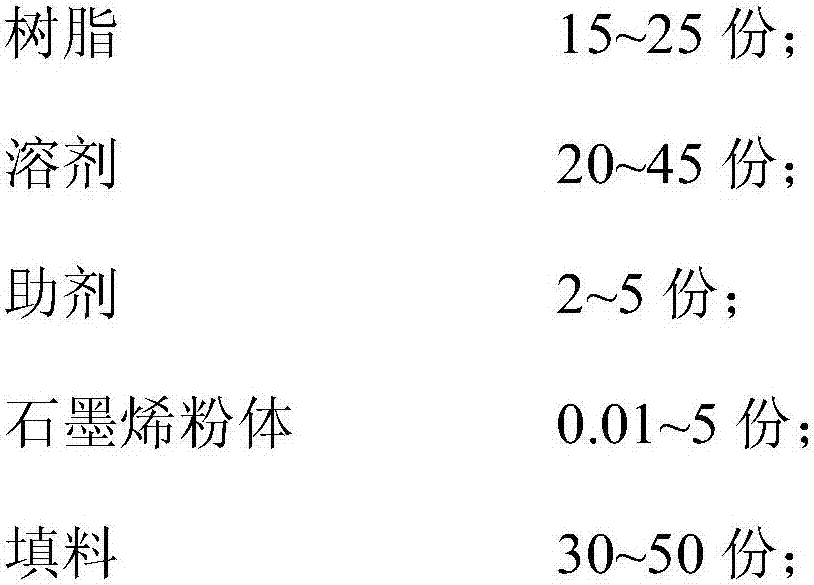

[0043] In parts by mass, component A includes the following components:

[0044]

[0045] Among them, the additives include anti-settling agents and thickeners, and the fillers are silicon carbide, zinc powder and talcum powder;

[0046] Component B includes solvent, accelerator and curing agent, and the mass ratio of solvent, accelerator and curing agent is 10:1:33.

[0047] The preparation method of above-mentioned heat dissipation coating based on graphene is as follows:

[0048] (1) According to the ratio of component A, pour the resin, solvent and dispersant into the container, stir and disperse at a speed of 1000rpm for 30min to obtain a resin solution;

[0049] (2) add graphene powder in resin solution and carry out stirring dispersion 60min according to rot...

Embodiment 2

[0053] Embodiment 2: The heat dissipation coating based on graphene powder provided by this embodiment is mainly composed of A component and B, and the mass ratio of A component and B component is 8:1;

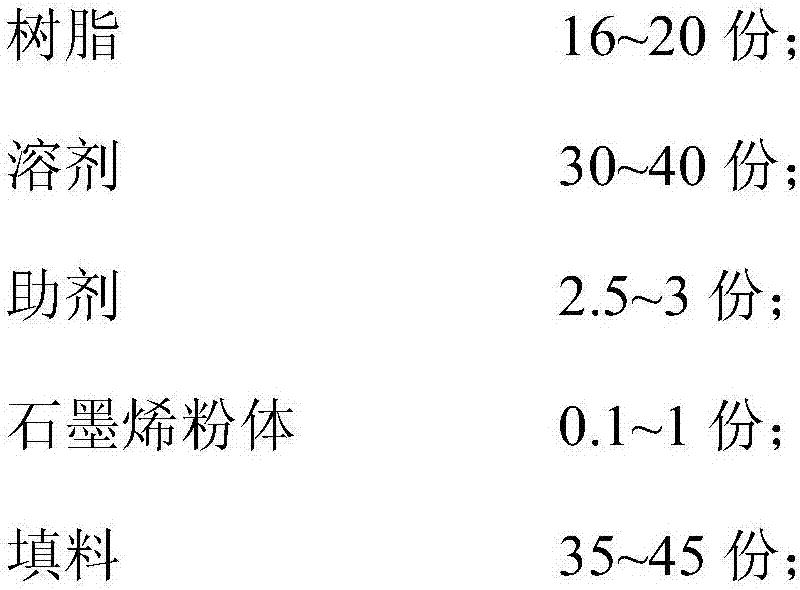

[0054] In parts by mass, component A includes the following components:

[0055]

[0056] Among them, the additives include anti-sedimentation agents and thickeners;

[0057] Component B includes solvent, accelerator and curing agent, and the mass ratio of solvent, accelerator and curing agent is 10:1:33.

[0058]The preparation method of above-mentioned heat dissipation coating based on graphene is as follows:

[0059] (1) According to the ratio of component A, pour the resin, solvent and dispersant into the container, stir and disperse at a speed of 1000rpm for 30min to obtain a resin solution;

[0060] (2) add graphene powder in resin solution and carry out stirring dispersion 60min according to rotating speed 1500rpm, obtain graphene resin dispersion liquid;

[0061]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com