Preparation method of anti-clogging bacteriostatic charged nanofiltration membrane

A nanofiltration membrane and anti-clogging technology, applied in the field of ultrafiltration, can solve the problems of reducing membrane flux, membrane fouling, and inorganic matter clogging membrane pores, etc., and achieve the effects of strengthening membrane pore strength, improving fouling resistance, and excellent adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

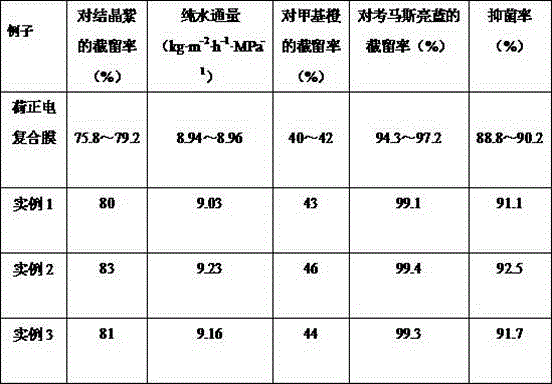

Examples

example 1

[0016] First weigh 10g of silver nitrate and 60mL of deionized water and place them in a 500mL three-necked flask. After stirring and mixing for 10 minutes, add 25mL of 10% ammonia solution by mass fraction to the three-necked flask dropwise, and control the dropping rate at 1mL / min. After completion, stir and mix at room temperature for 10 minutes to prepare a silver ammonia solution; add polyvinyl alcohol to a mass fraction of 8% sodium hydroxide solution at a mass ratio of 1:8, stir and mix and place in an Erlenmeyer flask to prepare a base body fluid, and then add the silver ammonia solution dropwise to the base liquid according to the mass ratio of 3:2, and control the dropping time for 1h. After washing with ethanol for 3 times, dry at 75°C for 6 hours to prepare nano-silver oxide; select hectorite, crush and grind it, and pass through a 200-mesh sieve to obtain hectorite powder, which is then weighed in parts by weight. Measure 45 parts of dodecylamine, 15 parts of nano...

example 2

[0019]First weigh 13g of silver nitrate and 65mL of deionized water and put them in a 500mL three-necked flask. After stirring and mixing for 13 minutes, add 28mL of 10% ammonia solution dropwise to the three-necked flask, and control the dropping rate at 2mL / min. After completion, stir and mix at room temperature for 13 minutes to prepare a silver ammonia solution; add polyvinyl alcohol to a mass fraction of 8% sodium hydroxide solution at a mass ratio of 1:8, stir and mix and place in an Erlenmeyer flask to prepare a base body fluid, and then add the silver ammonia solution dropwise to the base liquid according to the mass ratio of 3:2, and control the dropping time for 2 hours. After washing with ethanol for 4 times, dry at 78°C for 7 hours to prepare nano-silver oxide; select hectorite, pulverize and grind it, and pass through a 200-mesh sieve to obtain hectorite powder, which is then weighed in parts by weight. Measure 48 parts of dodecylamine, 18 parts of nano-silver oxi...

example 3

[0022] First weigh 15g of silver nitrate and 70mL of deionized water and put them in a 500mL three-neck flask. After stirring and mixing for 15 minutes, add 30mL of 10% ammonia solution dropwise to the three-necked flask, and control the dropping rate at 2mL / min. After completion, stir and mix at room temperature for 15 minutes to prepare a silver ammonia solution; add polyvinyl alcohol to a mass fraction of 8% sodium hydroxide solution at a mass ratio of 1:8, stir and mix and place in an Erlenmeyer flask to prepare a base Body fluid, then add the silver ammonia solution dropwise to the base liquid according to the mass ratio of 3:2, and control the dropping time for 2 hours. After washing with ethanol for 5 times, dry at 80°C for 8 hours to prepare nano-silver oxide; select hectorite, pulverize and grind it, pass through a 200-mesh sieve to obtain hectorite powder, and then weigh them in parts by weight. Measure 50 parts of dodecylamine, 20 parts of nano-silver oxide, 20 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com