Feed additive containing compound algae and preparation process of feed additive

A feed additive and seaweed technology, applied in animal feed, animal feed, additional food elements, etc., can solve the problems of relatively large difference in use effect and lack of national testing standards, so as to promote toxin discharge, prevent and control mycotoxin poisoning of livestock and poultry Related diseases, health protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

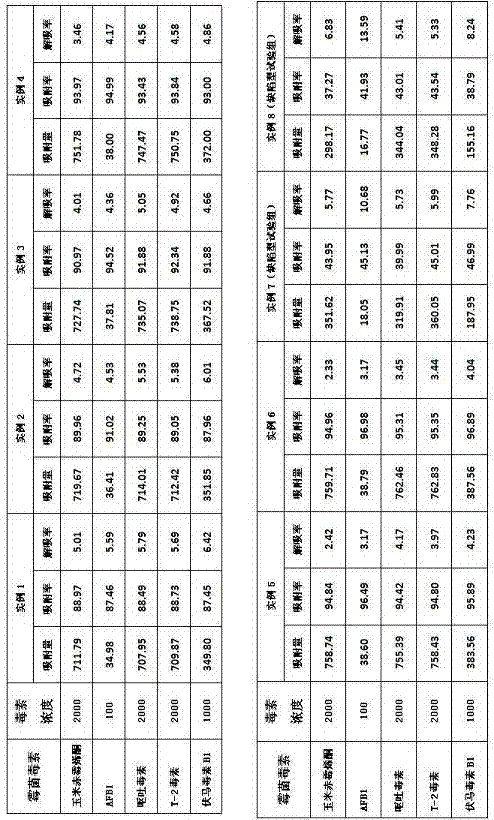

Examples

Embodiment 1

[0030] A feed additive containing compound seaweed is prepared through the following steps:

[0031] (1) Preparation of fucoidan: use macroalgae powder as raw material, add water 12-18 times its weight, stir evenly, boil for 10-15 minutes, cool down, keep warm at 28°C for 25-40 minutes, then add specific strain Pseudomonas. For the alginate lyase produced by sp.HZJ216, stir evenly, put the homogenate into a thermostat at 28°C for 3 hours, and add the enzyme in an amount of 0.05-0.08% of the weight of the homogenate. Stir continuously during the reaction. Boiling to terminate the enzymolysis reaction, and spray drying to obtain the finished product;

[0032] (2) Chlorella preparation: add water to the washed, dried and pulverized Ulva powder according to the ratio of material to liquid 1:35, extract at 90-100°C for 4 hours, after cooling, add chlorella polysaccharide degrading enzyme into the solution, and at the same time Add Mg2+ Enzymolyze at 40-50°C for 0.5-2h at a pH rang...

Embodiment 2

[0037] A feed additive containing compound seaweed is prepared through the following steps:

[0038] (1) Preparation of fucoidan: use wakame as raw material, add water 12-18 times its weight, stir evenly, boil for 10-15 minutes, cool down, keep warm at 28°C for 25-40 minutes, then add specific strain Pseudomonas. sp. For the alginate lyase produced by HZJ216, stir well, put the homogenate into a 28°C incubator for enzymolysis for 3 hours, the amount of enzyme added is 0.05-0.08% of the weight of the homogenate, keep stirring during the reaction, and stop by boiling Enzymolysis reaction, spray drying to get the finished product;

[0039] (2) Chlorella preparation: Add water to the washed, dried and crushed Enteromorpha powder according to the ratio of material to liquid 1:35, extract at 90-100°C for 4 hours, after cooling, add chlorophyll polysaccharide degrading enzyme into the solution, and at the same time Add Mg 2+ Enzymolyze at 40-50°C for 0.5-2h at a pH range of 7.5-8.5...

Embodiment 3

[0044] A feed additive containing compound seaweed is prepared through the following steps:

[0045] (1) Preparation of fucoidan: use sargassum powder as raw material, add water 12-18 times its weight, stir evenly, boil for 10-15 minutes, cool down, keep warm at 28°C for 25-40 minutes, then add specific strain Pseudomonas. For the alginate lyase produced by sp.HZJ216, stir evenly, put the homogenate into a thermostat at 28°C for 3 hours, and add the enzyme in an amount of 0.05-0.08% of the weight of the homogenate. Stir continuously during the reaction. Boiling to terminate the enzymolysis reaction, and spray drying to obtain the finished product;

[0046] (2) Chlorella preparation: add water to the washed, dried and pulverized Ulva powder according to the ratio of material to liquid 1:35, extract at 90-100°C for 4 hours, after cooling, add chlorella polysaccharide degrading enzyme into the solution, and at the same time Add Mg 2+ Enzymolyze at 40-50°C for 0.5-2h at a pH ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com