Catalyst for preparing aromatic polycarboxylic acid through liquid-phase oxidation

A polycarboxylic acid, liquid-phase oxidation technology, applied in physical/chemical process catalysts, preparation of organic compounds, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of low bromine consumption, high bromine content, impurities low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

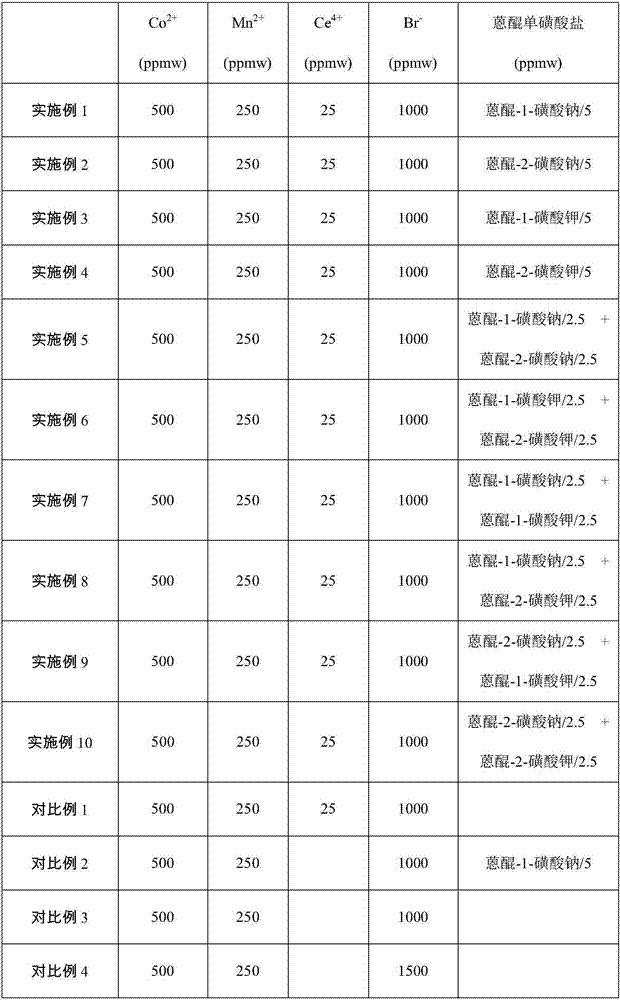

Examples

Embodiment 1

[0033] The reaction was carried out in a 1000ml titanium autoclave equipped with a magnetic stirrer, a gas delivery pipe, a reflux condenser, a thermocouple, and a bursting disc, with a stirring speed of 400rpm and heated by circulating hot oil. The reaction steps are as follows:

[0034] 1) Weigh 80g p-xylene, 400g acetic acid, 20g metal acetate (based on the whole solution, which contains 500ppmwCo 2+ 、250ppmw Mn 2+ 、25ppmw Ce 4+ ) and 0.55g 1,1,2,2-tetrabromoethane (based on the entire solution, bromine is 1000ppmw) and 5ppmw (based on the entire solution) anthraquinone-1-sodium sulfonate, mixed uniformly and added to the autoclave, Airtight.

[0035] 2) Add 2.0MPa nitrogen to carry out the airtight test for 30 minutes, and the pressure drop within 30 minutes is not more than 0.1MPa, which is qualified.

[0036] 3) Add nitrogen, the space velocity is 4h -1 , and start the stirrer, the stirring rate is 400rpm, the temperature is raised to 186° C., and the pressure is ma...

Embodiment 2

[0041] The reaction was carried out in a 1000ml titanium autoclave equipped with a magnetic stirrer, a gas delivery pipe, a reflux condenser, a thermocouple, and a bursting disc, with a stirring speed of 400rpm and heated by circulating hot oil. The reaction steps are as follows:

[0042] 1) Weigh 80g p-xylene, 400g acetic acid, 20g metal acetate (based on the whole solution, which contains 500ppmwCo 2+ 、250ppmw Mn 2+ 、25ppmw Ce 4+ ) and 0.55g of 1,1,2,2-tetrabromoethane (based on the entire solution, bromine is 1000ppmw) and 5ppmw (based on the entire solution) anthraquinone-2-sodium sulfonate, mixed evenly and added to the autoclave, Airtight.

[0043] 2) Add 2.0MPa nitrogen to carry out the airtight test for 30 minutes, and the pressure drop within 30 minutes is not more than 0.1MPa, which is qualified.

[0044] 3) Add nitrogen, the space velocity is 4h -1, and start the stirrer, the stirring rate is 400rpm, the temperature is raised to 186° C., and the pressure is mai...

Embodiment 3

[0049] The reaction was carried out in a 1000ml titanium autoclave equipped with a magnetic stirrer, a gas delivery pipe, a reflux condenser, a thermocouple, and a bursting disc, with a stirring speed of 400rpm and heated by circulating hot oil. The reaction steps are as follows:

[0050] 1) Weigh 80g p-xylene, 400g acetic acid, 20g metal acetate (based on the whole solution, which contains 500ppmwCo 2+ 、250ppmw Mn 2+ 、25ppmw Ce 4+ ) and 0.55g 1,1,2,2-tetrabromoethane (based on the entire solution, bromine is 1000ppmw) and 5ppmw (based on the entire solution) anthraquinone-1-potassium sulfonate, mixed uniformly and added to the autoclave, Airtight.

[0051] 2) Add 2.0MPa nitrogen to carry out the airtight test for 30 minutes, and the pressure drop within 30 minutes is not more than 0.1MPa, which is qualified.

[0052] 3) Add nitrogen, the space velocity is 4h -1 , and start the stirrer, the stirring rate is 400rpm, the temperature is raised to 186° C., and the pressure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com