A kind of preparation method of micron titanium foil

A micron-scale, titanium foil technology, applied in contour control, manufacturing tools, metal rolling, etc., can solve the problems of narrow use range, long production cycle, complex process, etc., to achieve short production cycle, small work roll diameter, internal The effect of uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

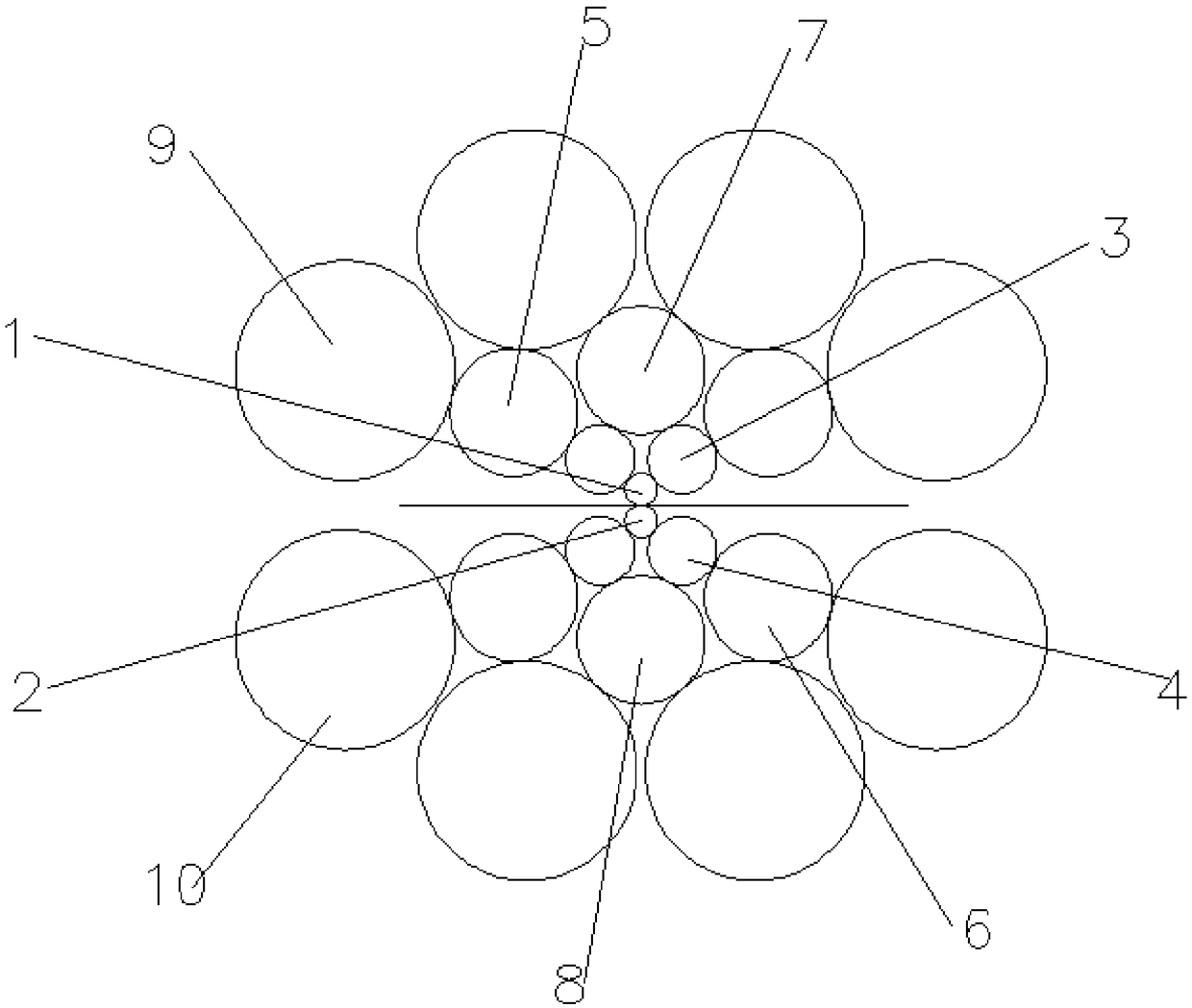

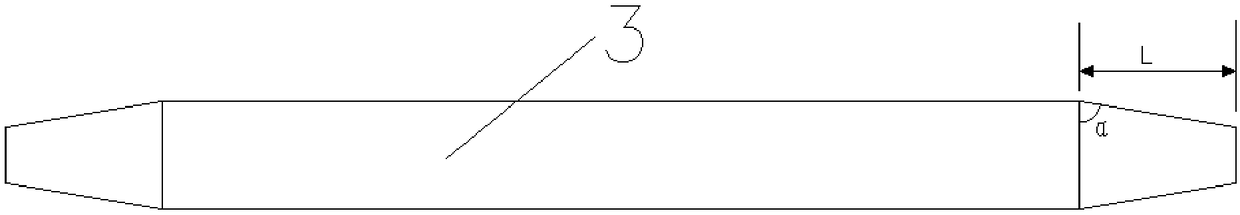

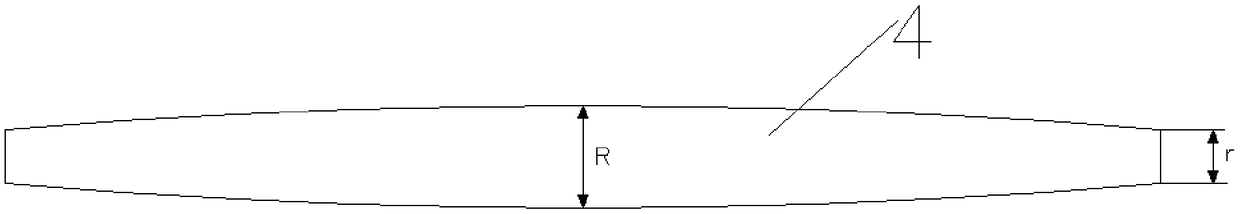

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of the micron titanium foil of this embodiment comprises the following steps:

[0041] Step 1. Send a titanium strip with a thickness of 0.198mm and a width of 120mm into a rolling mill for one-time rolling to obtain a semi-finished product of primary rolling titanium foil with a thickness of 0.058mm; Between 26.5kN and rolling tension between 110kg and 180kg; the titanium content in the titanium strip is not less than 99.95wt%, the hydrogen content is not more than 0.005wt%, the iron content is not more than 0.02wt%, and the oxygen content is not more than 0.05wt% %;

[0042] One rolling is 10-pass reversible rolling, the total reduction ratio is 70.7%, and the reduction ratios of 10 passes are 8.1%, 8.2%, 8.4%, 9.2%, 11.5%, 11.4%, 14.7%, 13.9%, 15.0%, 14.7%;

[0043] Step 2: Clean the primary rolled titanium foil semi-finished product obtained in step 1 and put it into a vacuum furnace, keep it warm for 100 minutes at 620°C, and the vacuum deg...

Embodiment 2

[0055] The preparation method of the micron titanium foil of this embodiment comprises the following steps:

[0056] Step 1. Send a titanium strip with a thickness of 0.196 mm and a width of 100 mm into a rolling mill for one-time rolling to obtain a semi-finished product of primary rolling titanium foil with a thickness of 0.056 mm; control the pressure of the pressure cylinder in the rolling mill to 25.5 kN to between 26.5kN and rolling tension between 105kg and 180kg; the titanium content in the titanium strip is not less than 99.95wt%, the hydrogen content is not more than 0.005wt%, the iron content is not more than 0.02wt%, and the oxygen content is not more than 0.05wt% %;

[0057] One rolling is 10-pass reversible rolling, the total reduction ratio is 71.4%, and the reduction ratios of 10 passes are 8.2%, 11.1%, 9.4%, 10.3%, 11.5%, 13.0%, 15.0%, 11.8%, 13.3%, 13.8%;

[0058] Step 2. Clean the primary rolled titanium foil semi-finished product obtained in step 1 and pu...

Embodiment 3

[0070] The preparation method of the micron titanium foil of this embodiment comprises the following steps:

[0071] Step 1. Send a titanium strip with a thickness of 0.2mm and a width of 80mm into the rolling mill for one-time rolling to obtain a semi-finished product of primary rolling titanium foil with a thickness of 0.054mm; control the pressure of the pressing oil cylinder in the rolling mill to 25.5kN~ Between 26.5kN and rolling tension between 100kg and 170kg; the titanium content in the titanium strip is not less than 99.95wt%, the hydrogen content is not more than 0.005wt%, the iron content is not more than 0.02wt%, and the oxygen content is not more than 0.05wt% %;

[0072] One rolling is 10-pass reversible rolling, the total reduction ratio is 73%, and the reduction ratios of 10 passes are 9.0%, 10.4%, 11.0%, 12.4%, 13.4%, 13.6%, 13.7%, 14.6%, 12.9%, 11.5%;

[0073] Step 2. Clean the primary rolled titanium foil semi-finished product obtained in step 1 and put it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com