Method for recycling waste liquor produced in preparation of reverse osmosis membrane

A technology of reverse osmosis membrane and recovery method, which is applied in the field of waste liquid recovery system, can solve the problems of complex procedures and low treatment efficiency, and achieve the effects of ensuring filtration efficiency, reducing concentration time, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

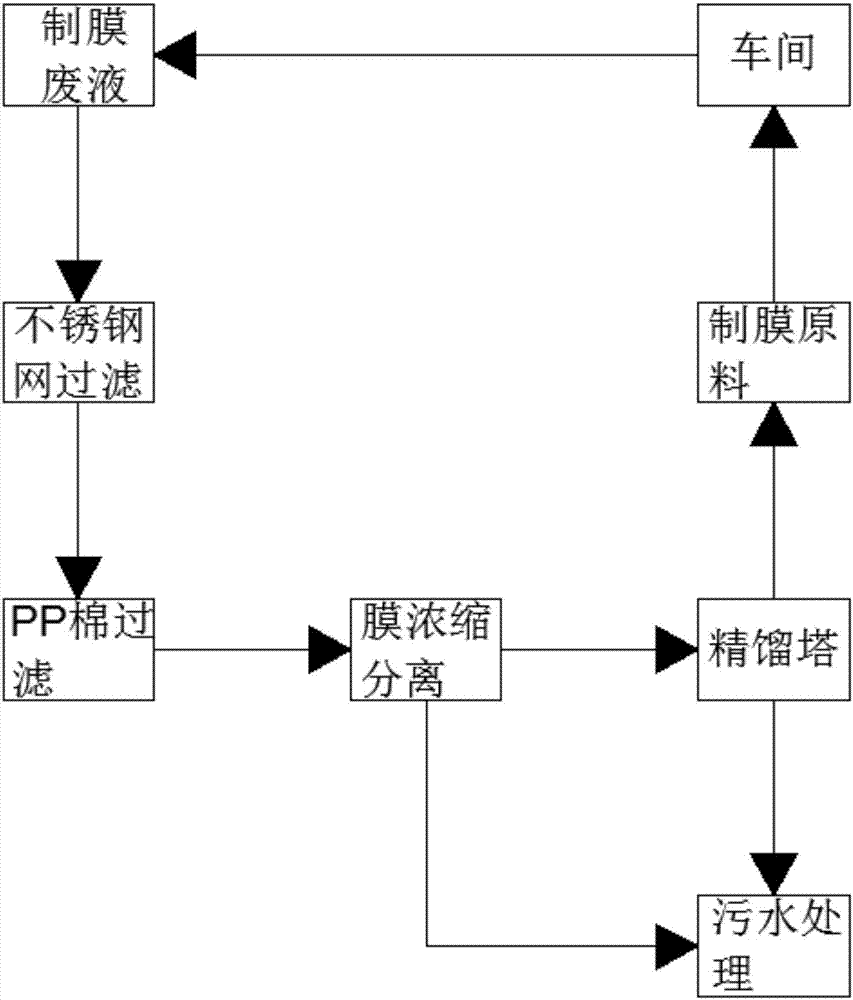

[0021] A method for recycling waste liquid from reverse osmosis membrane production, comprising the following steps:

[0022] (1) The low-concentration reverse osmosis membrane membrane-making waste liquid from the production workshop is pre-filtered through a stainless steel screen to obtain the low-concentration reverse osmosis membrane membrane-making waste liquid of the primary filter;

[0023] (2) The reverse osmosis membrane low-concentration membrane-making waste liquid filtered through step (1) is filtered through a PP cotton filter element;

[0024] (3) the reverse osmosis membrane film making waste liquid after the secondary filtration of step (2) is concentrated with a solvent-resistant separation membrane;

[0025] (4) More than 10% of the reverse osmosis membrane membrane-making waste liquid enters the rectification tower after being concentrated in step (3) and carries out rectification recovery to obtain high-purity reverse osmosis membrane membrane-making raw m...

Embodiment 2

[0032] A method for recycling waste liquid from reverse osmosis membrane production, comprising the following steps:

[0033] (1) The low-concentration reverse osmosis membrane membrane-making waste liquid from the production workshop is pre-filtered through a stainless steel screen to obtain the low-concentration reverse osmosis membrane membrane-making waste liquid of the primary filter;

[0034] (2) The reverse osmosis membrane low-concentration membrane-making waste liquid filtered through step (1) is filtered through a PP cotton filter element;

[0035] (3) the reverse osmosis membrane film making waste liquid after the secondary filtration of step (2) is concentrated with a solvent-resistant separation membrane;

[0036] (4) More than 10% of the reverse osmosis membrane membrane-making waste liquid enters the rectification tower after being concentrated in step (3) and carries out rectification recovery to obtain high-purity reverse osmosis membrane membrane-making raw m...

Embodiment 3

[0043] A method for recycling waste liquid from reverse osmosis membrane production, comprising the following steps:

[0044] (1) The low-concentration reverse osmosis membrane membrane-making waste liquid from the production workshop is pre-filtered through a stainless steel screen to obtain the low-concentration reverse osmosis membrane membrane-making waste liquid of the primary filter;

[0045] (2) The reverse osmosis membrane low-concentration membrane-making waste liquid filtered through step (1) is filtered through a PP cotton filter element;

[0046] (3) the reverse osmosis membrane film making waste liquid after the secondary filtration of step (2) is concentrated with a solvent-resistant separation membrane;

[0047] (4) More than 10% of the reverse osmosis membrane membrane-making waste liquid enters the rectification tower after being concentrated in step (3) and carries out rectification recovery to obtain high-purity reverse osmosis membrane membrane-making raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com