A kind of preparation method of hyperbranched shrinkage reducer

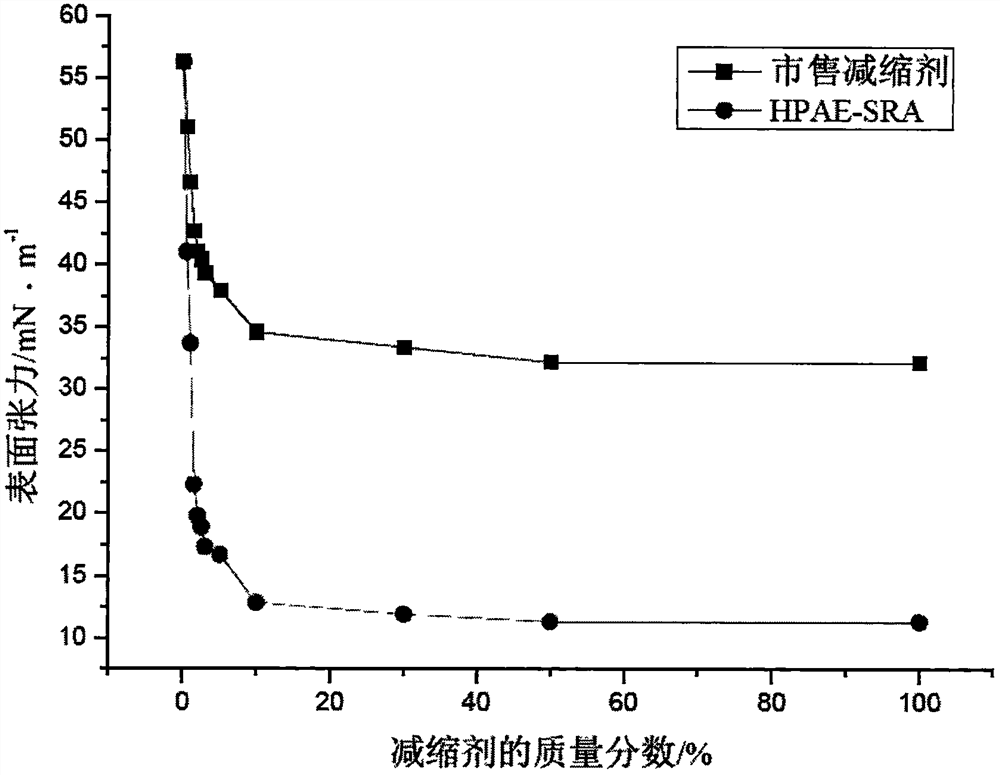

A technology of shrinkage reducing agent and hyperbranched polymer, which is applied in the field of preparation of hyperbranched shrinkage reducing agent, can solve the problems of reducing concrete strength, high cost, and flammability, and achieve good shrinkage reduction performance, enhanced flexural strength, and increased flexural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

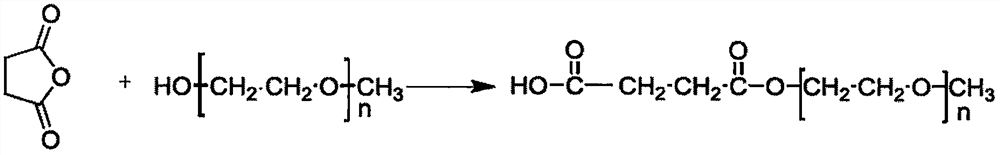

[0022] A preparation method of hyperbranched shrinkage reducer, comprising the steps of:

[0023] S1. Add 10.5g of diethanolamine and 10mL of anhydrous methanol to a 250mL three-necked flask connected with a condenser, slowly add 8.6g of methyl acrylate dropwise at room temperature, under nitrogen protection and magnetic stirring, and wait until the methyl acrylate is added dropwise , continue to stir for 30 minutes, then slowly raise the temperature to 40°C, keep the temperature constant for 4 hours, remove methanol within 30 minutes of vacuuming, and obtain a colorless transparent liquid, that is, obtain N, N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer;

[0024] S2. Using an approved one-step method, add 1.13g of trimethylolpropane, 4.82g of N,N-dihydroxyethyl-3-alanine methyl ester and 0.04g of p-toluenesulfonic acid into a 250mL three-necked flask , heated up to 120°C, mechanically stirred for 2.5 hours under the protection of nitrogen, and vacuumized for 1 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com