Preparation method of D-pantolactone

A technique for pantolactone and lactone, which is applied in the field of preparation of D-pantolactone, can solve the problems of low yield and low enzyme conversion rate, achieve low enzyme conversion rate improvement, improve optical purity and chemical purity, and obtain rate-boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

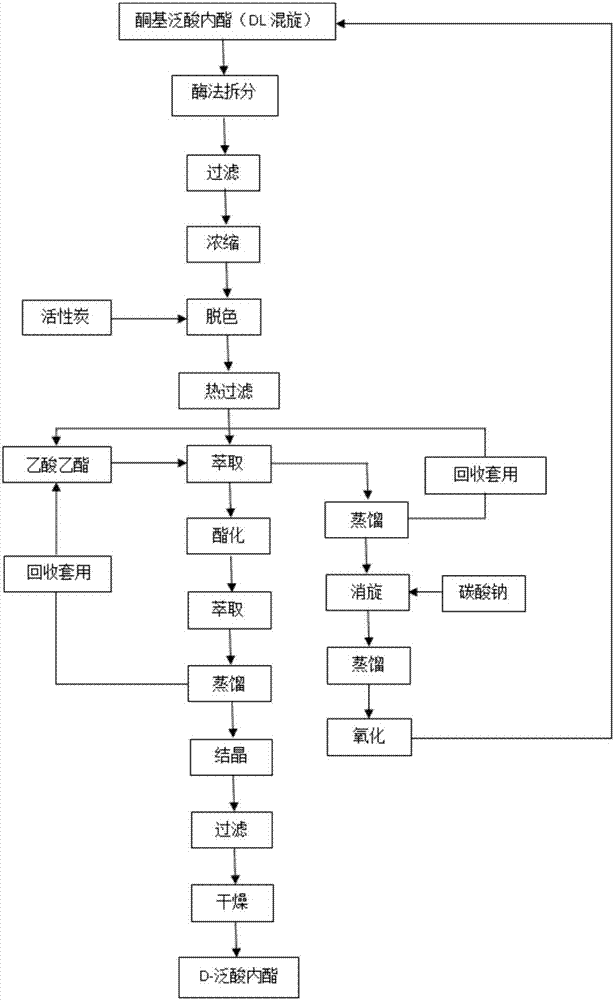

Method used

Image

Examples

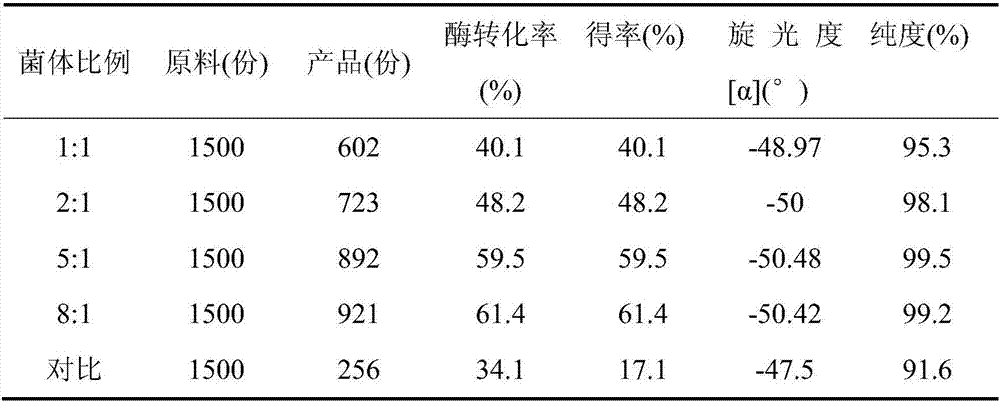

Embodiment 1

[0033] The raw materials used include: 1,500 parts of ketone pantothenate, 6,000 parts of water, 300 parts of compound enzyme (1:1 mixture of Rhodotorula and Monostella moniliformis), 600 parts of 10% ammonia water, 33,000 parts of ethyl acetate, activated carbon 1.5 parts, concentrated sulfuric acid (98%), said parts are parts by mass.

[0034] Its preparation method of D-pantothenic acid lactone is:

[0035] 1) Dissolve the raw material ketopantothenate in water, add compound enzymes for enzymolysis, the enzymolysis temperature is 40-50°C, the enzymolysis time is 35h, and the pH during the enzymolysis process is adjusted to 7 by ammonia water;

[0036] 2) Filtrate, filter out the mycelium (composite enzyme) for reuse, concentrate the filtrate to 60% of the original volume, and use 0.03% (the quality of activated carbon relative to the quality and dosage of ketopantothenic acid lactone) under the condition of 75-85°C Activated carbon decolorization, hot filtration (filtering...

Embodiment 2

[0040] The raw materials used include: 1,500 parts of ketone pantothenate, 6,000 parts of water, 300 parts of compound enzyme (mixture of Rhodotorula minor and Rhodotorula moniliformis 2:1), and 600 parts of 10% ammonia water. 33000 parts of ethyl acetate, 1.5 parts of activated carbon, and the consumption of concentrated sulfuric acid is undecided, and the said parts are parts by mass.

[0041] Its preparation method of D-pantothenic acid lactone is:

[0042] Dissolve the raw material ketopantothenate in water, add compound enzymes for enzymolysis, enzymolysis temperature 30-40°C, enzymolysis time 40h, use ammonia water to adjust the pH of the enzymolysis process to 7; filter and filter out the mycelium Repeated use, the filtrate was concentrated to 70% of the original volume, under the condition of 75-85 ° C, use 0.02% activated carbon for decolorization, heat filtration, add ethyl acetate (EA:H 2 O=1.1:1) Six rounds of extraction, distillation and recovery of ethyl acetate...

Embodiment 3

[0044]D-pantothenolactone, its raw materials include: 1500 parts of ketone pantothenate lactone, 6000 parts of water, 300 parts of enzyme (5:1 mixture of Rhodotorula minor and Vernis moniliformis), 600 parts of 10% ammonia water. 33000 parts of ethyl acetate, 1.5 parts of activated carbon, and the consumption of concentrated sulfuric acid is undecided, and the said parts are parts by mass.

[0045] Its preparation method of D-pantothenic acid lactone is:

[0046] Dissolve the raw material ketopantothenate in water, add compound enzymes for enzymolysis, enzymolysis temperature 30-40°C, enzymolysis time 40h, use ammonia water to adjust the pH of the enzymolysis process to 7; filter and filter out the mycelium For repeated use, the filtrate is concentrated to 60% of the original volume. Under the condition of 75-85 ° C, use 0.05% activated carbon for decolorization, heat filtration, add ethyl acetate (EA:H 2 O=1.1:1) Six rounds of extraction, distillation and recovery of ethyl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com