Antistatic finishing agent for spinning

An antistatic finishing agent and thickener technology, applied in textiles, papermaking, fiber processing, etc., can solve problems such as harming doctors and patients, anesthesia explosion, etc., and achieve good washability, durability, and superior antistatic properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

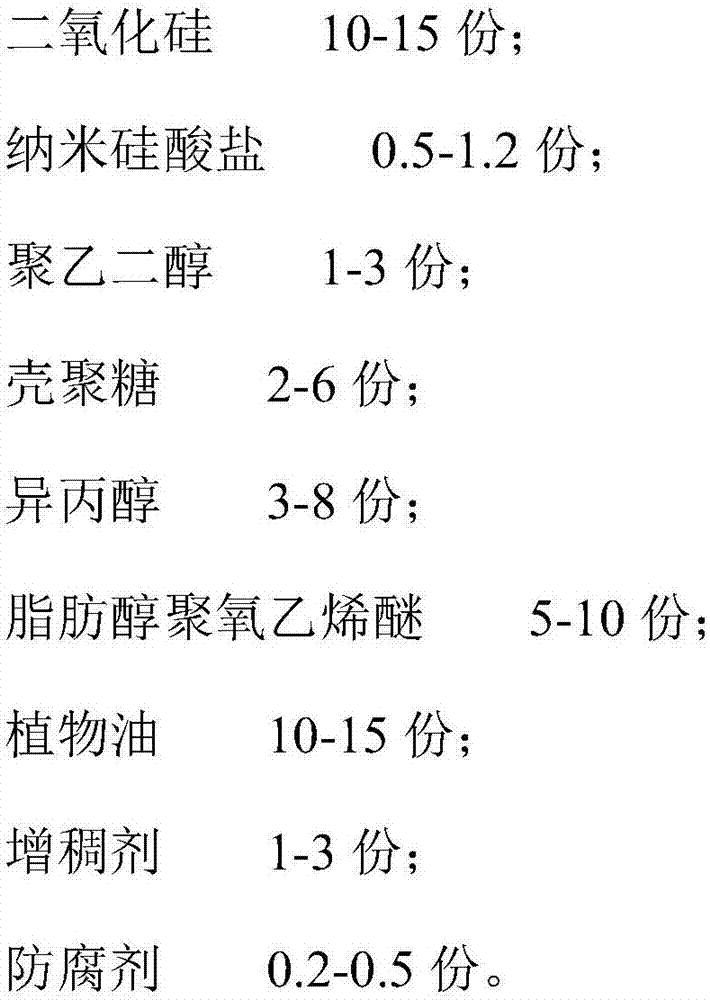

[0015] An antistatic finishing agent for textiles, comprising silicon dioxide, nano silicate, polyethylene glycol, chitosan, isopropanol, fatty alcohol polyoxyethylene ether, vegetable oil, thickener and preservative, its composition points, in parts by weight, are:

[0016]

Embodiment 2

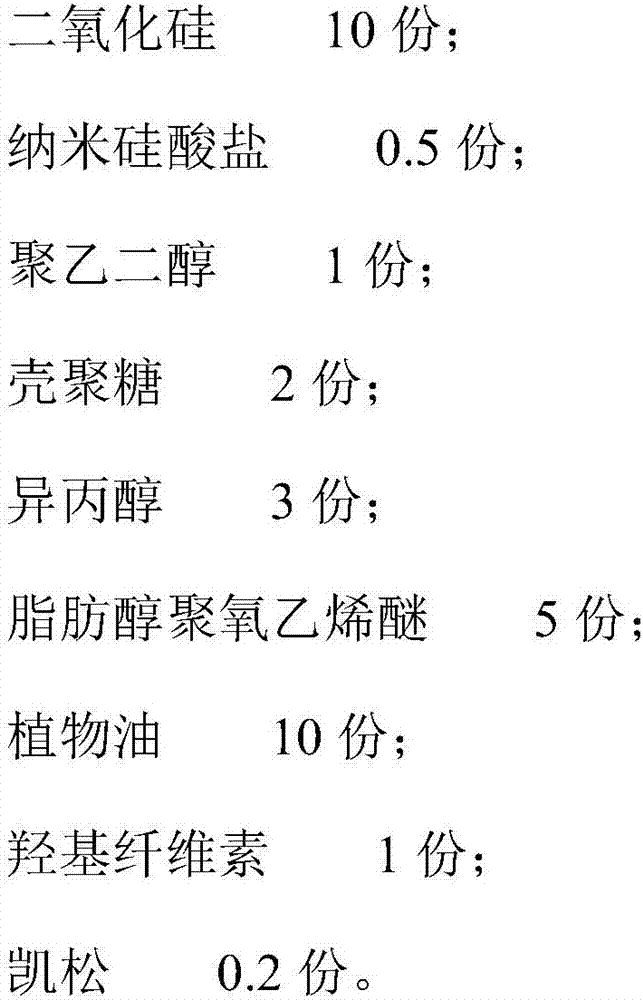

[0018] An antistatic finishing agent for textiles, comprising silicon dioxide, nano silicate, polyethylene glycol, chitosan, isopropanol, fatty alcohol polyoxyethylene ether, vegetable oil, thickener and preservative, its composition points, in parts by weight, are:

[0019]

Embodiment 3

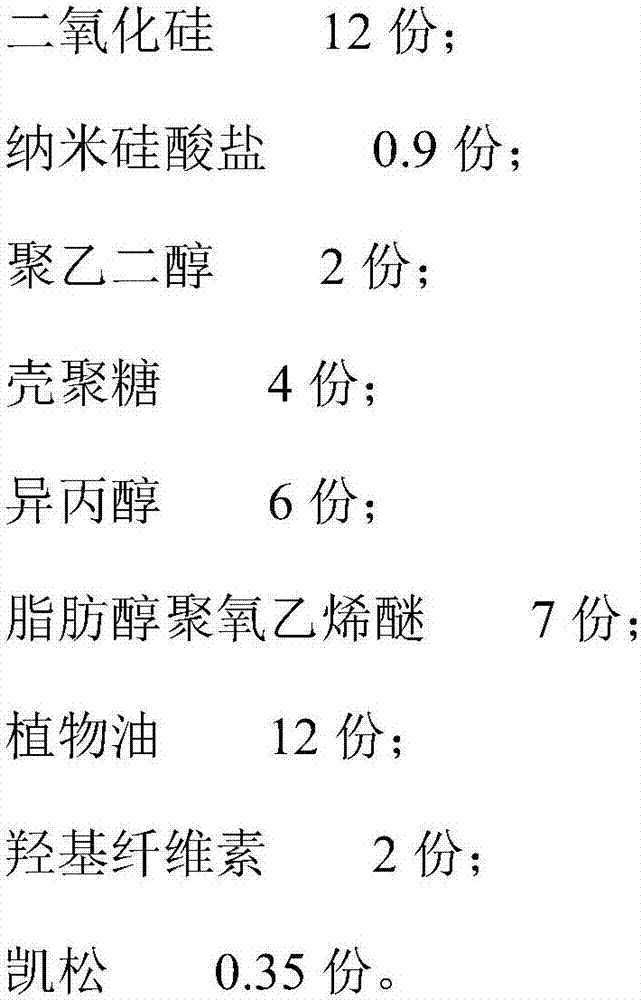

[0021] An antistatic finishing agent for textiles, comprising silicon dioxide, nano silicate, polyethylene glycol, chitosan, isopropanol, fatty alcohol polyoxyethylene ether, vegetable oil, thickener and preservative, its composition points, in parts by weight, are:

[0022]

[0023]

[0024] The beneficial effects of the present invention are: the finishing agent has excellent antistatic function, can be mixed with cationic or nonionic textile finishing auxiliaries or used as an alkali weight reduction accelerator, the content of each component is small, and has no irritation to the skin Allergic reaction, no potential carcinogenicity, excellent antibacterial finishing function, good antistatic durability and good washability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com