Preparation method for corncob-shaped polyaniline-supported halloysite nanotube modified polypropylene

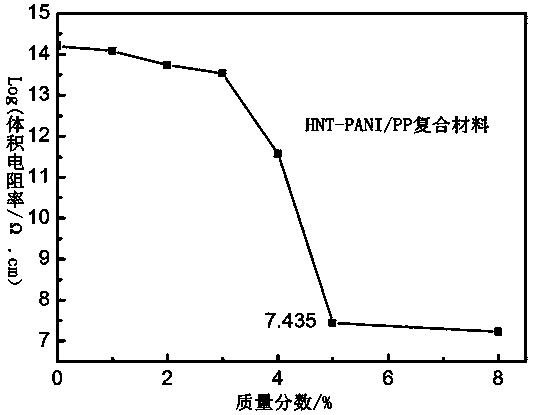

A technology of halloysite nanotubes and polyaniline, applied in nanotechnology, plastic recycling, recycling technology, etc., can solve the problems of accelerated aging rate of PP materials, decline in mechanical properties, high surface resistance, etc., and achieve scientific and reasonable preparation methods , increase added value, improve the effect of conductive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of corncob-shaped polyaniline loaded halloysite nanotube modified polypropylene, the specific steps are as follows:

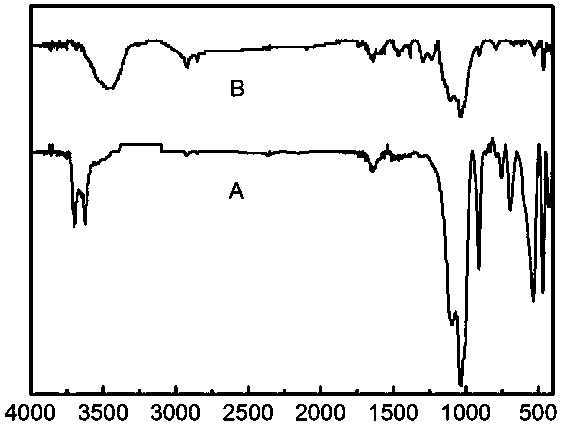

[0026] 1) Halloysite is purified by acid leaching, ground and sieved, ultrasonically dispersed in deionized water, aniline monomer and ammonium persulfate initiator are added in a low-temperature reaction bath, and the low-temperature polymerization reaction is performed for 24 hours, then stood for 2 hours, and used to remove Wash with ionic water and absolute ethanol until colorless, and vacuum-dry to obtain dark green HNT-PANI powder; wherein, the mass ratio of halloysite nanotubes to aniline monomer is 1:0.5-1:2; The molar ratio of ammonium sulfate is 1:0.67;

[0027] 2) The HNT-PANI powder is melt-extruded and granulated with the composite material, PP and compatibilizer PP-g-MAH in a co-rotating twin-screw extruder. Among them, the reaction temperature of each section of the twin-screw extruder is 180, 185, 190, 190, 195, 195,...

Embodiment 1

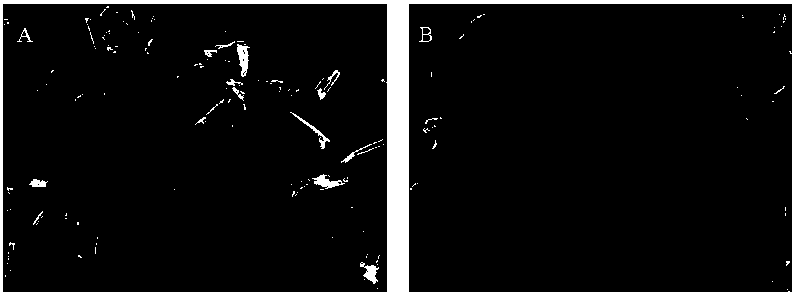

[0030] 1) Preparation of corncob-shaped HNT-PANI powder: Halloysite is purified by acid leaching, ground and sieved, then dried in an oven, take 10g of halloysite, 750mL of 1mol / L HC and 10mL of distilled aniline monomer Pour into a 1500mL round bottom flask and ultrasonically disperse at 100W for 1h, place them together in an ice-water bath and magnetically stir for 0.5h, add 15.6g of ammonium persulfate to 250mL of HCl, stir until completely dissolved, and cool in an ice bath for 5 min , poured into a separatory funnel; then control the rate of addition, drop the ammonium persulfate solution within 0.5-1.0h, continue to react for 24h, let stand for 2h, and wash and filter with deionized water and absolute ethanol for many times until The filtrate is transparent, colorless and neutral, then put into a vacuum drying oven, and dry to obtain dark green nanometer HNT-PANI powder;

[0031] 2) HNT-PANI / PP composite material: Take 5g of the nano-powder prepared in step 1), PP-g-MAH ...

Embodiment 2

[0033] In step 2), 10g of HNT-PANI nanopowder, 39.2g of PP-g-MAH and 450.8g of PP were added, and the other condition parameters were the same as in Example 1, and finally a 2wt% HNT-PANI / PP composite material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com