A kind of reduced graphene oxide-poly-p-phenylenediamine/tpu composite film

A poly-p-phenylenediamine, composite film technology, applied in the fields of carbon compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of high surface resistance, general dispersion, electrostatic charge accumulation, etc., to improve thermal conductivity, preparation The method is scientific and reasonable, and the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of reduced graphene oxide-poly-p-phenylenediamine / TPU composite film, the specific steps are as follows:

[0030] 1) After cold treatment of graphite, put it in a low temperature reaction bath, slowly add concentrated sulfuric acid while stirring, and add potassium permanganate in batches within 3 hours, and then heat to 50 ° C after low temperature reaction at 4 ° C for 0.5 hours, Continue to react for 12h, then add deionized water, stir for 15min, and dropwise add 30% hydrogen peroxide, pickle and water until neutral, freeze-dry to obtain lamellar graphene oxide;

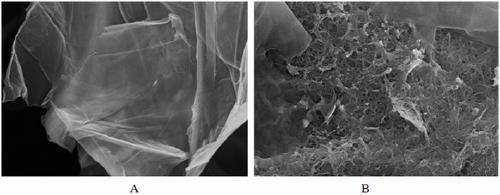

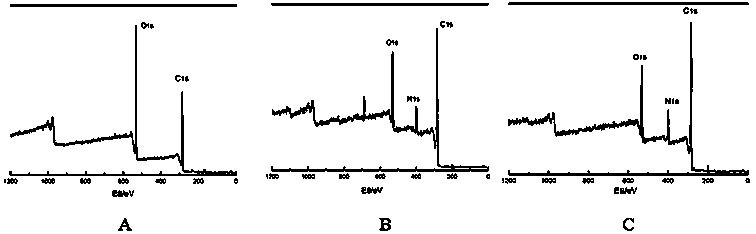

[0031] 2) Ultrasonic disperse graphene oxide in deionized water, add p-phenylenediamine monomer and ammonium persulfate initiator to the low temperature reaction bath, conduct low temperature polymerization reaction below 4 °C for 24 hours, then stand for 2 hours, use deionized water and Washed with absolute ethanol until colorless, freeze-dried to obtain GO-PPDA powder; wherein, the ma...

Embodiment 1

[0040] 1) Improved Hummers method to prepare graphene oxide: firstly, 1 g of graphite was cold-treated, then 45 mL of 98% concentrated sulfuric acid and 5 mL of concentrated phosphoric acid were slowly added to the low-temperature reaction bath, stirred and mixed, and 7 g of potassium permanganate was divided into three parts within 3 hours. The mixed acid was added in batches, and the reaction system was moved to a water bath and heated to 50°C after a low temperature reaction for half an hour. After the reaction was continued for 12 hours, 1000 mL of deionized water was added to obtain a red-brown graphite suspension. After stirring for 15 minutes, 30% hydrogen peroxide was added dropwise. , obtain bright yellow graphite diluent, finally carry out pickling with 3% hydrochloric acid solution, and then wash to neutrality to obtain graphene oxide gel, and graphene oxide gel is subjected to freeze-drying treatment to obtain fluffy graphene oxide ( GO) solid;

[0041] 2) Synthesi...

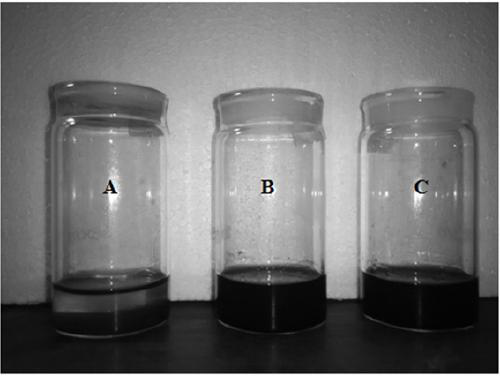

Embodiment 2

[0046] In step 4), 0.038 g of RGO-PPDA nano-powder was added, and other conditions and parameters were the same as those in Example 1, and finally a 0.5% RGO-PPDA / TPU composite film was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com