Electrochemical-membrane separation water treating device, treating method and application thereof

A technology of water treatment device and treatment method, which is applied in chemical instruments and methods, sterilization/microdynamic water/sewage treatment, water/sewage treatment, etc. Change the molecular structure, slow down membrane fouling, and improve the effect of effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

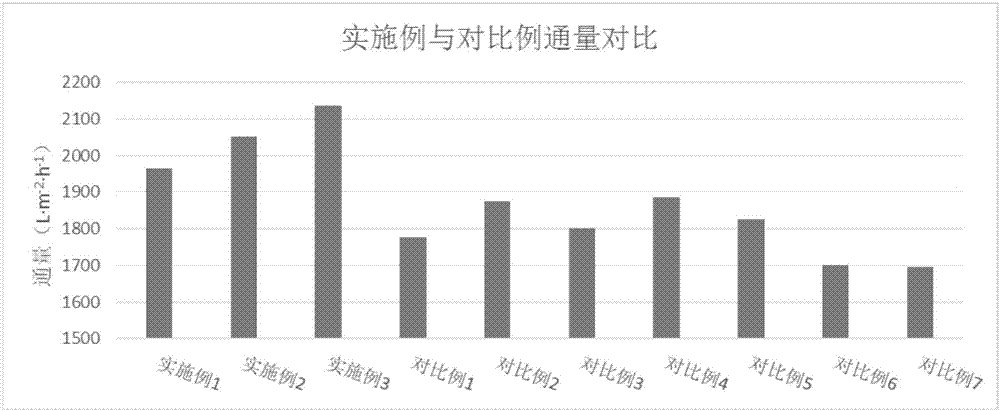

Embodiment 1

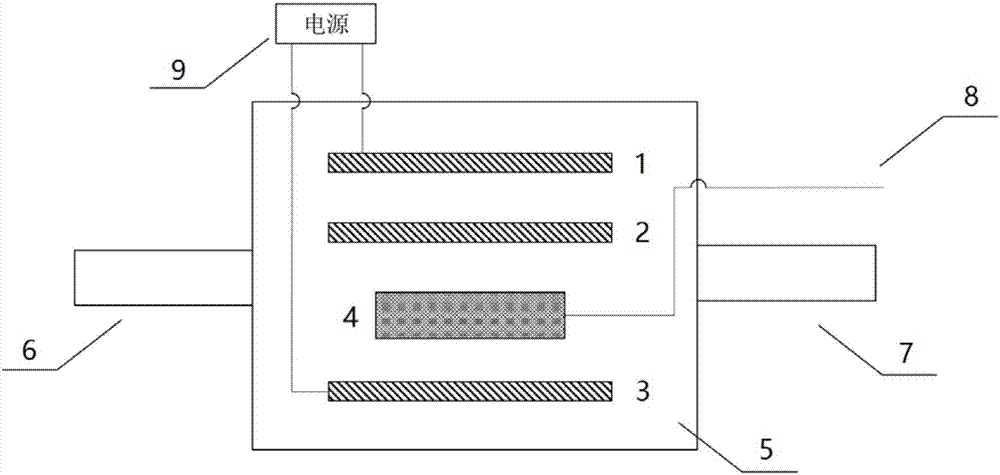

[0051] This embodiment provides an electrochemical-membrane separation water treatment device and a treatment method thereof. The device includes a reaction tank 5 in which a membrane module 4 is arranged, and one side of the membrane module 4 is parallel from the inside to the outside A sensing electrode 2 and an anode plate 1 are arranged on the membrane assembly 4, the other side of the membrane assembly 4 is arranged with a cathode plate 3 parallel to the membrane assembly 4, and the anode plate 1 and the cathode plate 3 are connected to an external power source 9;

[0052] A water inlet 6 is provided on one side of the main body of the reaction tank 5, and a water return port 7 is provided on the side opposite to the water inlet; the main body of the reactor 5 is provided with a membrane module water outlet 8. The membrane module water outlet 8 and the membrane module 4 Connected.

[0053] Wherein, the anode plate 1 is a titanium ruthenium electrode; the number of anode plates...

Embodiment 2

[0064] This embodiment provides an electrochemical-membrane separation water treatment device and a treatment method thereof. The structure of the device is referred to embodiment 1. The difference is that the number of anode plates 1 is two, and the number of cathode plates 3 is Two, the membrane module 4 is a hollow fiber membrane; the membrane element in the membrane module 4 is an ultrafiltration membrane.

[0065] The device is used to treat industrial sewage, in which the TOC content is 450ppm, the turbidity is 60NTU, and the processing capacity is 3000L·m -2 ·H -1 .

[0066] The processing method refers to Example 1, the difference is: in step (1), the current density is adjusted to 10A / m 2 , The transmembrane pressure difference is 35kPa.

[0067] In this embodiment, the membrane flux after pollution in step (a) is 2463L·m -2 ·H -1 , The contact angle is 64.22°, the apparent porosity of the filter cake layer is 14.77%, and the pore size of the filter cake layer is 13 nm.

[00...

Embodiment 3

[0070] This embodiment provides an electrochemical-membrane separation water treatment device and a treatment method thereof. Refer to Embodiment 1 for the structure of the device.

[0071] The device is used to treat industrial wastewater, in which the TOC content is 450ppm, the turbidity is 60NTU, and the processing capacity is 3500L·m -2 ·H -1 .

[0072] The processing method refers to Example 1, the difference is: in step (1), the current density is adjusted to 15A / m 2 , The transmembrane pressure difference is 25kPa.

[0073] In this embodiment, the membrane flux after pollution in step (a) is 2990.75L·m -2 ·H -1 , The contact angle is 61.34°, the apparent porosity of the filter cake layer is 15.87%, and the pore size of the filter cake layer is 16 nm.

[0074] The drinking water obtained after treatment has a TOC content of 0.5 ppm, a turbidity reduced to 0 NTU, and a pollutant separation efficiency of 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane flux | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com