Preparation method of polyether ether ketone terpolymer

A terpolymer and polyether ether ketone technology, which is applied in the field of preparation of polyether ether ketone terpolymers, can solve problems such as weak temperature resistance, achieve easier control of the production process, improve stability, reduce The effect of pH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

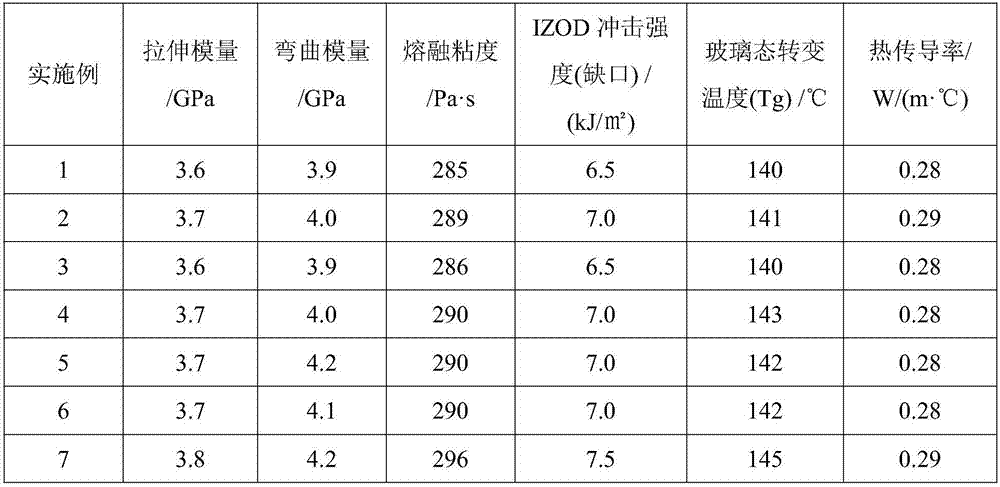

Examples

Embodiment 1

[0019] First, introduce high-purity nitrogen (purity ≥99.9995%) to the reactor equipped with thermometer, air inlet pipe, reflux condensing device and torque display stirrer to deoxygenate, and maintain a certain nitrogen flow (2m 3 / h), add 335g diphenyl sulfone, after heating and dissolving, add 110g 4,4'-difluorobenzophenone in turn, after stirring evenly, when heated to 150 ℃, the sodium bicarbonate and potassium bicarbonate powders are pre-dried , Weigh 82.0g of sodium bicarbonate and 5.0g of potassium bicarbonate and quickly add them into the reaction system. After stirring evenly, continue to heat up to 185°C and react at a constant temperature for 1h. At this temperature, 52.5g of pre-mixed p-benzene The mixture of diphenol and 8.9g of 4,4'-biphenol was slowly added into the reaction system. The addition time was 20min, the stirring speed was increased, the temperature was continued to rise, the temperature was raised to 270°C within 15min, the temperature was kept cons...

Embodiment 2

[0021] According to the same method as Example 1, only the amount of diphenyl sulfone was changed to 350 g to obtain a polyether ether ketone terpolymer.

Embodiment 3

[0023] According to the same method as Example 1, only the amount of sodium bicarbonate was changed to 78.5g, and the amount of potassium bicarbonate was changed to 9.6g to obtain a polyether ether ketone terpolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com