Highlight polypropylene material capable of improving color change of weld line

A polypropylene material and welding line technology, applied in the field of high-gloss polypropylene materials, can solve the problems of discoloration stripes or nicks at the welding point, and achieve the effect of reducing surface energy, low melting point and promoting dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment.

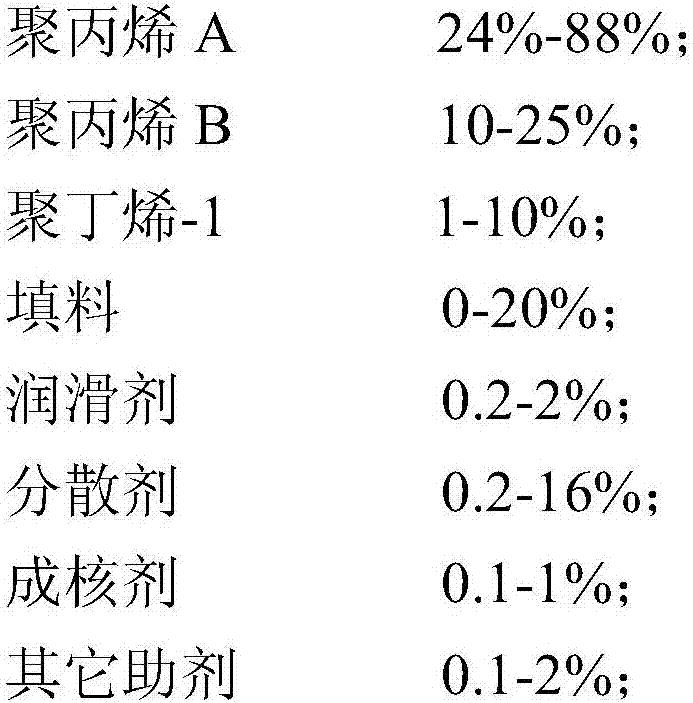

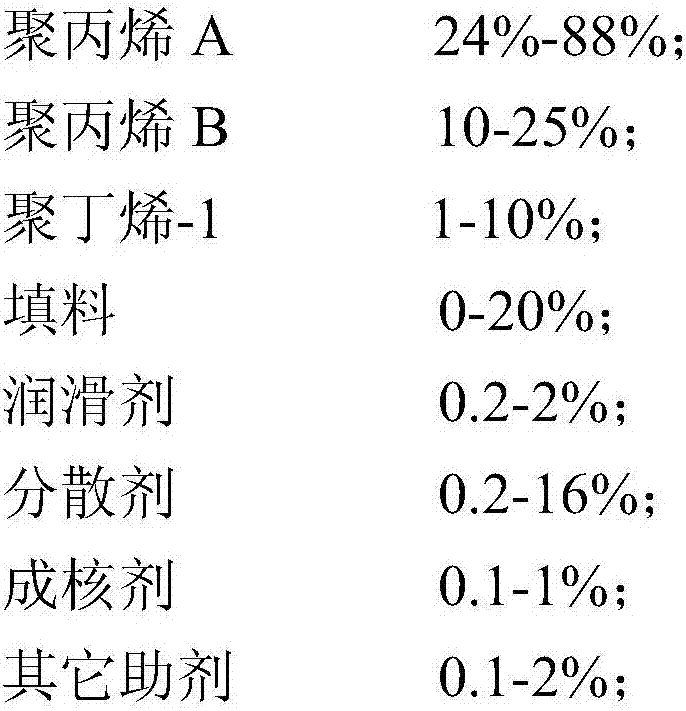

[0024] The high-gloss polypropylene material for improving the discoloration of weld lines is characterized in that: by weight percentage, it includes:

[0025] Polypropylene A 24%-88%. Polypropylene A is one or a mixture of homopolypropylene and copolypropylene with a melt flow rate of 8-50g / 10min;

[0026] Polypropylene B 10-25%, the melt flow rate of polypropylene B is 8-130g / 10min;

[0027] Polybutene-1 1-10%, polybutene-1 is a random copolymer polypropylene with a melt flow rate of 12-50g / 10min;

[0028] Filler 0-20%, the filler is calcium carbonate, talcum powder, barium sulfate, wollastonite, kaolin, or a mixture of two or more, the particle size of the filler is 6μm-100nm;

[0029] Lubricant 0.2-2%, the lubricant is composed of lubricant A and lubricant B, the compounding ratio is 1:2; Among them, lubricant A is stearic acid, calcium stearate, zinc stearate, silane Couplin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com