Super-tough polylactic acid-based nanocomposite material with balanced rigidity and toughness and preparation method thereof

A nano-composite material, lactic acid-based technology, applied in the field of polylactic acid-based nanocomposite materials, super-tough polylactic acid-based nanocomposite materials and their preparation, can solve the problem that the combination of polylactic acid and natural rubber cannot be improved, and the micron-scale silica is not suitable. It has a reinforcing effect, and is not aware of problems such as failure in advance, and achieves the effect of increasing strength, improving compatibility, and delaying the development of cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

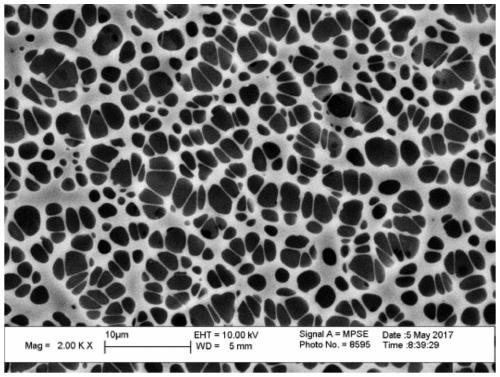

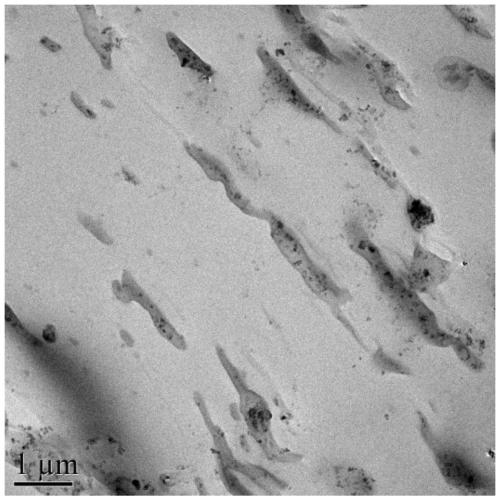

Embodiment 1

[0047] Select polylactic acid as the matrix resin (Zhejiang Hisun Biomaterials Co., Ltd., racemic polylactic acid (PDLLA)), and NR (Shanghai Sanlian Industrial Co., Ltd., Hainan No. 1 standard rubber, SCRWF) as the matrix rubber. In order to reduce rubber elasticity, increase plasticity, and facilitate processing, natural rubber is masticated on an open mill, and fumed silica (particle size 20nm) with a mass fraction of 2% of natural rubber is mixed with the masticated rubber uniform. In this example, the mass ratio of polylactic acid and natural rubber is 70 / 30. First, polylactic acid and 0.2% antioxidant 1010 based on the total mass of the matrix rubber were added to a torque rheometer with a temperature and a rotational speed of 170 °C and 60 r / min, respectively, and melted and blended for 3 minutes, followed by adding natural rubber and gas phase Method silica mixture, after mixing for 3 minutes, add 1.5% dicumyl peroxide and 0.15% TAC of the matrix rubber for dynamic vul...

Embodiment 2

[0049] Select polylactic acid as the matrix resin (Zhejiang Hisun Biomaterials Co., Ltd., racemic polylactic acid (PDLLA)), and NR (Shanghai Duokang Industrial Co., Ltd., Hainan No. 1 standard rubber, SCRWF) as the matrix rubber. In order to reduce rubber elasticity, increase plasticity, and facilitate processing, natural rubber is masticated on an open mill, and fumed silica (particle size 20nm) with a mass fraction of 2% of natural rubber is mixed with the masticated rubber uniform. In this example, the mass ratio of polylactic acid and natural rubber is 75 / 25. First, polylactic acid and 0.3% antioxidant 1010 based on the total mass of the matrix rubber were added to a torque rheometer with a temperature and a rotational speed of 170°C and 60 r / min, respectively, and melted and blended for 3 minutes, followed by adding natural rubber and gas phase French silica mixture, after mixing for 3 minutes, add 2% di-tert-butyl peroxide of the mass of the matrix rubber and 0.2% TAIC ...

Embodiment 3

[0051]Select polylactic acid as the matrix resin (Zhejiang Hisun Biomaterials Co., Ltd., racemic polylactic acid (PDLLA)), and NR (Shanghai Duokang Industrial Co., Ltd., Hainan No. 1 standard rubber, SCRWF) as the matrix rubber. In order to reduce rubber elasticity, increase plasticity, and facilitate processing, natural rubber is masticated on an open mill, and fumed silica (particle size 20nm) with a mass fraction of 4% of natural rubber is mixed with masticated rubber uniform. In this example, the mass ratio of polylactic acid and natural rubber is 75 / 25. First, polylactic acid and 0.3% antioxidant 1010 based on the total mass of the matrix rubber were added to a torque rheometer with a temperature and a rotational speed of 170°C and 60 r / min, respectively, and melted and blended for 3 minutes, followed by adding natural rubber and gas phase French silica mixture, after mixing for 3 minutes, add 2% di-tert-butyl peroxide of the mass of the matrix rubber and 0.2% TAIC of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com