Cultivation technique of safflower camellia oleifera by chopping off anvil

A technology for safflower camellia and broken anvil, which is applied in the field of safflower oil camellia broken anvil and split cultivation, can solve the problems of poor shading and ventilation effect of a grafted part, high cost of asexual reproduction, large consumption of propagating materials and the like, and achieves good ventilation. , Grafting survival rate is high, the effect of environmental pollution is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

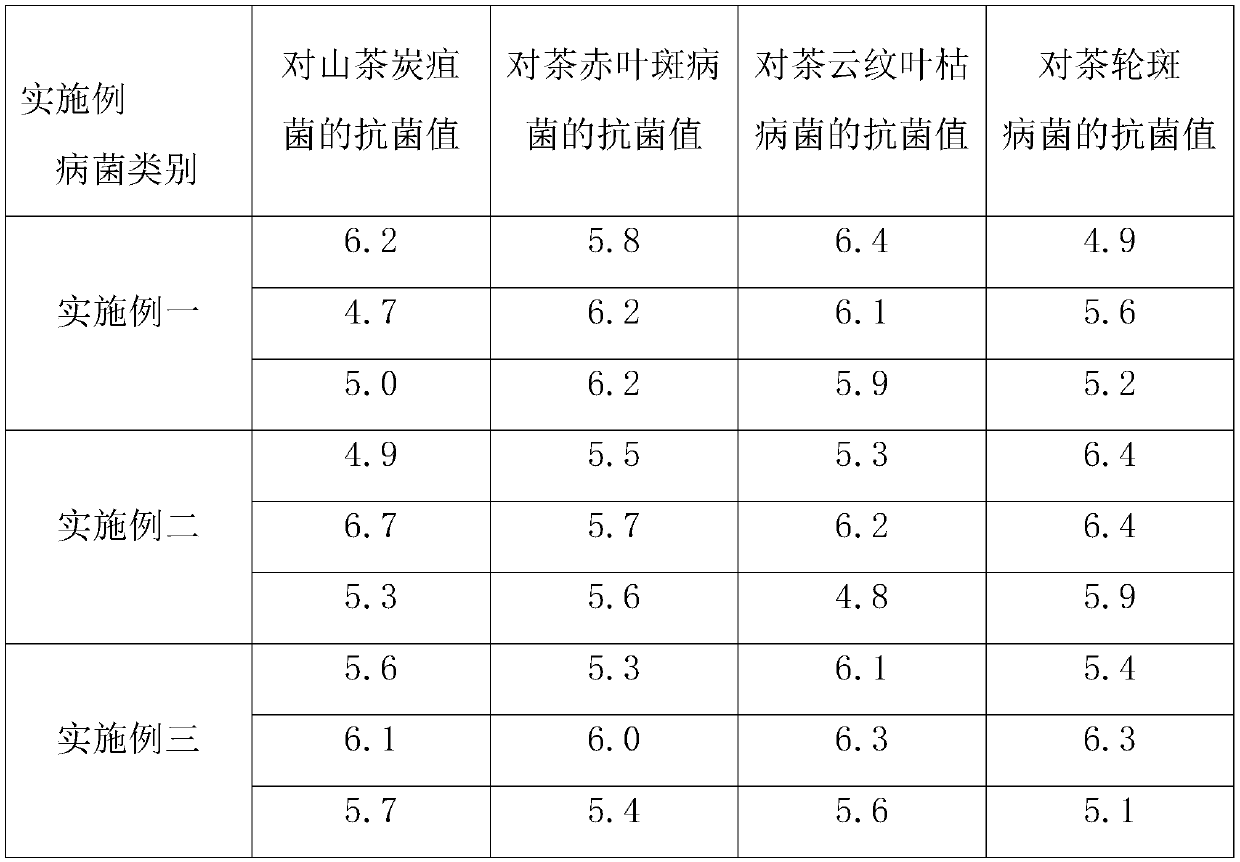

preparation Embodiment 1

[0034] Take graphene oxide, add 10 times the volume of absolute ethanol, after fully stirring, add 0.1 times the weight of the graphene oxide coupling agent γ~glycidoxypropyltrimethoxysilane, and stir in a water bath at 80°C for 30 minutes , Remove the supernatant liquid by centrifugation, and fully dry the lower product at 80°C to obtain functionalized graphene oxide. Add the functionalized graphene oxide obtained to 6 times the volume of the 1mol / L acetic acid aqueous solution. Disperse for 1 hour under 32KHz ultrasound and 45r / s dispersion speed, then add pyraclostrobin powder 0.5 times the weight of graphene oxide, stir until the solution is homogeneous, continue stirring, and add 10 times the weight of graphene oxide successively Chitosan powder, 0.01 times the volume of glycerol in aqueous acetic acid solution, then stirred at room temperature for 10 hours, and left standing for 2 hours to obtain a mixed solution; the obtained mixed solution was cast on a glass slide with ...

preparation Embodiment 2

[0036] Take graphene oxide and add 10 times the volume of absolute ethanol. After fully stirring, add 0.2 times the weight of graphene oxide coupling agent γ~glycidoxypropyltrimethoxysilane, and stir in a water bath at 80°C for 30 minutes. The supernatant was removed by centrifugation, and the lower product was fully dried at 80°C to obtain functionalized graphene oxide. The functionalized graphene oxide obtained was added to 18 times the volume of 1mol / L acetic acid aqueous solution at 32KHz Disperse for 1 hour at a dispersion speed of 45r / s, and then add pyraclostrobin powder 0.8 times the weight of graphene oxide, stir until the solution is homogeneous, continue stirring, and add 15 times the weight of graphene oxide successively Chitosan powder, 0.03 times the volume of glycerol in aqueous acetic acid solution, then stirred at room temperature for 10 hours, and left standing for 2 hours to obtain a mixed solution; the obtained mixed solution was cast on a glass slide with a ...

preparation Embodiment 3

[0038] Take graphene oxide and add 10 times the volume of anhydrous ethanol. After fully stirring, add 0.15 times the weight of graphene oxide coupling agent γ~glycidoxypropyltrimethoxysilane, and stir in a water bath at 80°C for 30 minutes. The supernatant was removed by centrifugation, and the lower product was fully dried at 80°C to obtain functionalized graphene oxide. The functionalized graphene oxide was added to 12 times the volume of 1mol / L acetic acid aqueous solution at 32KHz Disperse for 1 hour at a dispersing speed of 45r / s, and then add pyraclostrobin powder 0.6 times the weight of graphene oxide, stir until the solution is homogeneous, continue stirring, and add graphene oxide 10-15 times successively The weight of chitosan powder, 0.02 times the volume of glycerol in the acetic acid aqueous solution, then stirred at room temperature for 10 hours, and then stood for 2 hours to obtain a mixed solution; the obtained mixed solution was cast on a glass slide with a wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com