Method for preparing water body defluorination material from steam pressure concrete blocks

A technology for concrete blocks and fluorine materials, which is applied in the field of waste resource utilization, can solve the problems of high cost of fluorine removal, secondary pollution of steam pressurized concrete blocks, etc., and achieves the effect of high specific surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the method for preparing a water body defluoridation material using waste steam pressurized concrete blocks is as follows:

[0028] (1) Use a small hammer crusher to crush the discarded steam-pressurized concrete blocks, and control the output particle size to ≤6mm.

[0029](2) Put the material crushed in step (1) into a ball mill for ball milling. During the ball milling process, add lignosulfonate with a mass of 0.07% of the mass of the ball milled material for surface dispersion treatment, and control the ball milling time to 40 minutes.

[0030] (3) The ground material is selected and separated by an airflow classifier, and the particles with a particle size of ≤80 μm are collected to obtain the water body defluoridation material.

Embodiment 2

[0032] In this embodiment, the method for preparing a water body defluoridation material using waste steam pressurized concrete blocks is as follows:

[0033] (1) Use a small hammer crusher to crush the discarded autoclaved aerated concrete blocks, and control the output particle size to ≤6mm.

[0034] (2) Put the crushed material in step (1) into a ball mill for ball milling. During the ball milling process, add 0.08% lignosulfonate, 0.04% ethylene glycol and 0.05% triisopropanol, respectively Amines were used for surface dispersion treatment, and the ball milling time was controlled to be 35 minutes.

[0035] (3) The ground material is selected and separated by an airflow classifier, and the particles with a particle size of ≤80 μm are collected to obtain the water body defluoridation material.

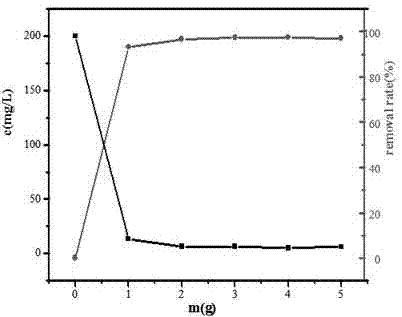

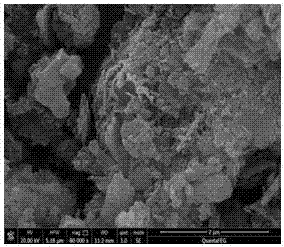

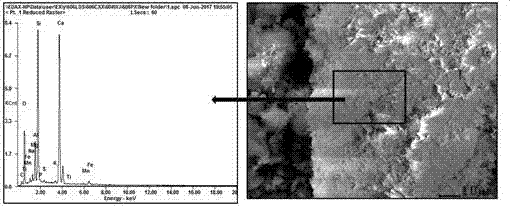

[0036] figure 2 The microscopic scanning electron microscope picture of the water body defluoridation material prepared for Example 2. It can be seen from the figure that the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com