A kind of biological bacterial fertilizer prepared from livestock and poultry waste and its preparation method

A technology of livestock and poultry waste and biological bacterial fertilizer, applied in the field of biological fertilizer, can solve problems such as rising agricultural production costs, declining fertility, and affecting sustainable agricultural production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

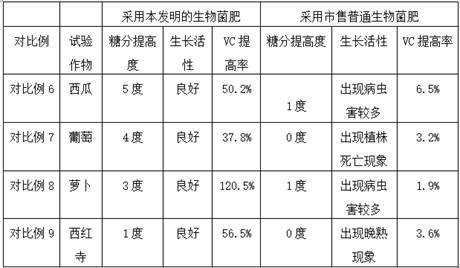

Examples

Embodiment 1

[0067]Example 1 A method for preparing biological bacterial fertilizer prepared by the harmless treatment of livestock and poultry wastes includes the following steps:

[0068](1) Mix pig manure, cow manure, artificial feed, and straw forage in a ratio of 10:5:2:3 to obtain livestock and poultry waste;

[0069](2) Preparation of carrier material;

[0070]a. After drying, the corncob with a moisture content of 3% is crushed into particles, and the particles are filtered through a method of sieving to filter out the corncob layer particles larger than 3μm and smaller than 1μm;

[0071]b. Activate the corn cob particles after sieving; activation solution is used for activation; the component of the activation solution is cocamidopropyl betaine with a concentration of 5%; the activation treatment time is 5 minutes; the activation temperature is 50°C;

[0072]c. Put the activated corn cob layer particles into a centrifugal spin dryer for spin drying at a speed of 800 r / min and spin drying time 3 min;

[0...

Embodiment 2

[0091]Example 2 A preparation method of biological bacterial fertilizer prepared by the harmless treatment of livestock and poultry waste, including the following steps:

[0092](1) Mix pig manure, cow manure, artificial feed, and straw forage in a ratio of 10:5:2:3 to obtain livestock and poultry waste;

[0093](2) Preparation of carrier material; the preparation method of the carrier material:

[0094]a. After drying, the corncob with a moisture content of 4% is crushed into particles, and the particles are filtered through a method of sieving to filter out the corncob layer particles larger than 3 μm and smaller than 1 μm;

[0095]b. Activate the corn cob particles after sieving; activation solution is used for activation; the component of the activation solution is cocamidopropyl betaine with a concentration of 6%; the activation treatment time is 7 minutes; the activation temperature is 65°C The micropores inside the particles of the corncob layer after the activation treatment are enlarge...

Embodiment 3

[0115]Example 3 A method for preparing biological bacterial fertilizer prepared by the harmless treatment of livestock and poultry wastes includes the following steps:

[0116](1) Mix pig manure, cow manure, artificial feed, and straw forage in a ratio of 10:5:2:3 to obtain livestock and poultry waste;

[0117](2) Preparation of carrier material;

[0118]a. Crush the corncob with a moisture content of 5% after drying into particles, and filter the particles through a sieve method to filter out the corncob layer particles larger than 3μm and smaller than 1μm;

[0119]b. Activate the corn cob particles after sieving; activation solution is used for activation; the component of the activation solution is cocamidopropyl betaine with a concentration of 7%; the activation treatment time is 10 minutes; the activation temperature is 70°C The micropores inside the particles of the corncob layer after the activation treatment are enlarged, which improves the space capacity of the corncob layer and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com