A preparation method of pendimethalin and the application of the waste water produced by the preparation method in the treatment of chlorpyrifos waste water

A pendimethalin and amylamine technology, which is applied in the preparation of pendimethalin and the application field of treating chlorpyrifos wastewater, can solve the problems of excessive discharge of three wastes, increase of production cost of enterprises, environmental pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Unless otherwise specified, the content of each component used below is a mass percentage.

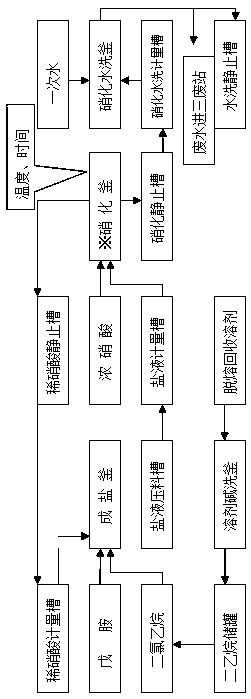

[0060] S1. Synthetic Nitrification

[0061] Such as figure 1 As shown, using pentylamine as a raw material, pentylamine reacts with dilute nitric acid to form a quaternary ammonium salt. In this embodiment, pentylamine is put into a salt-forming kettle and dissolved in methanol, wherein the molar ratio of pentylamine to methanol is 1:1200. After being fully dissolved, it reacts with dilute nitric acid to form a quaternary ammonium salt, in which the molar ratio of pentylamine to dilute nitric acid is 1:1.5.

[0062] The quaternary ammonium salt reacts with concentrated nitric acid to produce pendimethalin nitrated oil phase. In this embodiment, the generated quaternary ammonium salt is added to concentrated nitric acid under the protection of nitrogen for nitration reaction to generate pendimethalin nitrated oil phase, wherein the molar ratio of amylamine to concentrated nitric acid ...

Embodiment 2

[0072] S1. Synthetic Nitrification

[0073] Such as figure 1 As shown, using pentylamine as a raw material, pentylamine reacts with dilute nitric acid to form a quaternary ammonium salt. In this embodiment, pentylamine is put into the salt-forming kettle and dissolved in dichloroethane, wherein the molar ratio of pentylamine to dichloroethane is 1:60. After being fully dissolved, it reacts with dilute nitric acid to form a quaternary ammonium salt, in which the molar ratio of pentylamine to dilute nitric acid is 1:0.8.

[0074] The quaternary ammonium salt reacts with concentrated nitric acid to produce pendimethalin nitrated oil phase. In this embodiment, the generated quaternary ammonium salt is added to concentrated nitric acid under the protection of nitrogen for nitration reaction to generate pendimethalin nitrated oil phase, wherein the molar ratio of amylamine to concentrated nitric acid is 1:1.6. After the nitrification is completed, the nitrified oil phase of pendimethal...

Embodiment 3

[0084] S1. Synthetic Nitrification

[0085] Such as figure 1 As shown, using pentylamine as a raw material, pentylamine reacts with dilute nitric acid to form a quaternary ammonium salt. In this embodiment, pentylamine was put into a salt-forming kettle and dissolved in chloroform, where the molar ratio of pentylamine to chloroform was 1:40. After being fully dissolved, it reacts with dilute nitric acid to form a quaternary ammonium salt, in which the molar ratio of pentylamine to dilute nitric acid is 1:0.6.

[0086] The quaternary ammonium salt reacts with concentrated nitric acid to produce pendimethalin nitrated oil phase. In this embodiment, the generated quaternary ammonium salt is added to concentrated nitric acid under the protection of nitrogen for nitration reaction to generate pendimethalin nitrated oil phase, wherein the molar ratio of amylamine to concentrated nitric acid is 1:1.2. After the nitrification is completed, the nitrified oil phase of pendimethalin and nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com