Selective conversion method of waste residue of picloram production

A kind of amiloride, selective technology, applied in the field of resources and environment, to achieve the effect of simple operation, solve the expansion of material liquid, and realize the effect of multi-effect utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

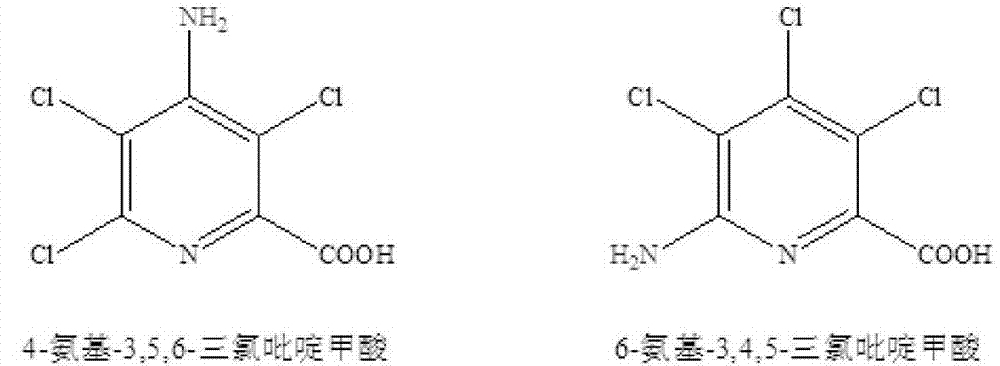

Image

Examples

Embodiment 1

[0044]300 g of isoamyl alcohol, 100 g of amiloride production waste residue, 70 g of isoamyl nitrite, and 50 g of sodium chloride were sequentially added to a 1000 mL four-necked flask. At room temperature, 80 g of concentrated hydrochloric acid was added for diazotization reaction. After the reaction was completed, 30 g of CuCl was added, and the flask was moved into a water bath at 45°C.

[0045] After the reaction, the reaction liquid was lowered to room temperature, 600 g of water was added, mixed and stirred, and filtered, and the filtrate was separated to obtain isoamyl alcohol, which could be recycled. Move the filter cake into a flask containing an appropriate amount of water, slowly add a certain amount of NaOH solution, and adjust the pH value to stabilize at 9-10. Filtrate, slowly add a certain amount of hydrochloric acid to the filtrate, stir for 20 minutes and then filter, the filter cake is washed with water and dried to obtain the finished product. The dry wei...

Embodiment 2

[0047] Its step is with embodiment 1, and difference is: used the recovery isoamyl alcohol in embodiment 1 and added 20g fresh isoamyl alcohols and reacted. A dry weight of 67.78g was obtained, wherein the content of amiloride was 75.62%, the content of clopyralid was 22.39%, and the product yield was 67.78%.

Embodiment 3

[0049] The steps are the same as in Example 1, except that ethanol is used to replace isoamyl alcohol as a solvent for the reaction. The dry weight of the obtained product was 69.24g, wherein the content of amiloride was 80.47%, the content of clopyralid was 17.30%, and the product yield was 69.24%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com