Low-smoke, halogen-free and flame-retardant thermoplastic elastomer cable material with ultralow smoke amount

A smoke-yielding, thermoplastic technology, used in plastic/resin/wax insulators, circuits, insulators, etc., can solve the problems of high smoke release, flexibility, low hardness, cable damage, etc. The effect of increased tensile strength and high market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

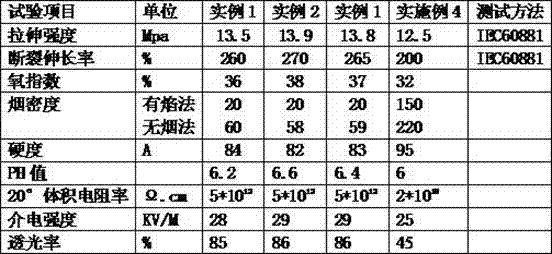

Examples

Embodiment 1

[0037] A thermoplastic low-smoke halogen-free flame-retardant elastomer cable material with ultra-low smoke generation. The production process of the cable material is as follows: (1) grafting 12 parts of organic silicone resin, 11 parts of sodium silicate, and maleic anhydride Pour 3 parts of polyolefin elastomer and 4 parts of diammonium hydrogen phosphate into the mixer, and mix the mixture at 115°C for 25 minutes;

[0038] (2) Mix the cedar bark, pine bark, and Northeast yew, dry and pulverize, add ethanol to the pulverized mixture, soak for 3 hours, and then take it out;

[0039] (3) Add 11 parts of chitosan, 2 parts of citrus extract, and 3 parts of ginger extract to the reaction mixture in step (2), and stir the mixture at 65°C for 6 hours, then put the mixture into To the pressure device, and the mixture was reacted for 22 minutes under the condition of 88MPa;

[0040] (4) Mix the reacted mixture in step (1) with the reacted mixture in step (3), add 50 parts of flame ...

Embodiment 2

[0065] A thermoplastic low-smoke halogen-free flame-retardant elastomer cable material with ultra-low smoke generation. The production process of the cable material is as follows: (1) grafting 12 parts of organic silicone resin, 10 parts of sodium silicate, and maleic anhydride Pour 5 parts of polyolefin elastomer and 3 parts of diammonium hydrogen phosphate into the mixer, and mix the mixture at 125°C for 20 minutes;

[0066] (2) Mix cedar bark, pine bark, and Northeast yew, dry and pulverize, add ethanol to the pulverized mixture, soak for 4 hours, and then take it out;

[0067] (3) Add 11 parts of chitosan, 5 parts of citrus extract, and 1 part of ginger extract to the reaction mixture in step (2), and stir the mixture at 68°C for 6 hours, then put the mixture into To the pressure device, and the mixture was reacted for 21 minutes under the condition of 92MPa;

[0068] (4) After mixing the reacted mixture in step (1) with the reacted mixture in step (3), add 58 parts of fl...

Embodiment 3

[0093] A thermoplastic low-smoke halogen-free flame-retardant elastomer cable material with ultra-low smoke generation. The production process of the cable material is as follows: (1) grafting 13 parts of organic silicone resin, 8 parts of sodium silicate, and maleic anhydride Pour 6 parts of polyolefin elastomer and 1 part of diammonium hydrogen phosphate into the mixer, and mix the mixture at 130°C for 20 minutes;

[0094] (2) Mix cedar bark, pine bark, and Northeast yew, dry and pulverize, add ethanol to the pulverized mixture, soak for 4 hours, and then take it out;

[0095] (3) Add 7 parts of chitosan, 5 parts of citrus extract, and 1 part of ginger extract to the mixture reacted in step (2), and stir the mixture at 68°C for 4 hours, then put the mixture into Into the pressure device, and make the mixture react for 19 minutes under the condition of 93MPa;

[0096] (4) Mix the reacted mixture in step (1) with the reacted mixture in step (3), add 70 parts of flame retardan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com