Modified PVC (Polyvinyl Chloride) composite material and preparation method thereof

A composite modification, PVC resin technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of product surface roughness, poor ductility, melt fracture, etc., achieve low density, improve creep resistance, Effect of improving low temperature impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

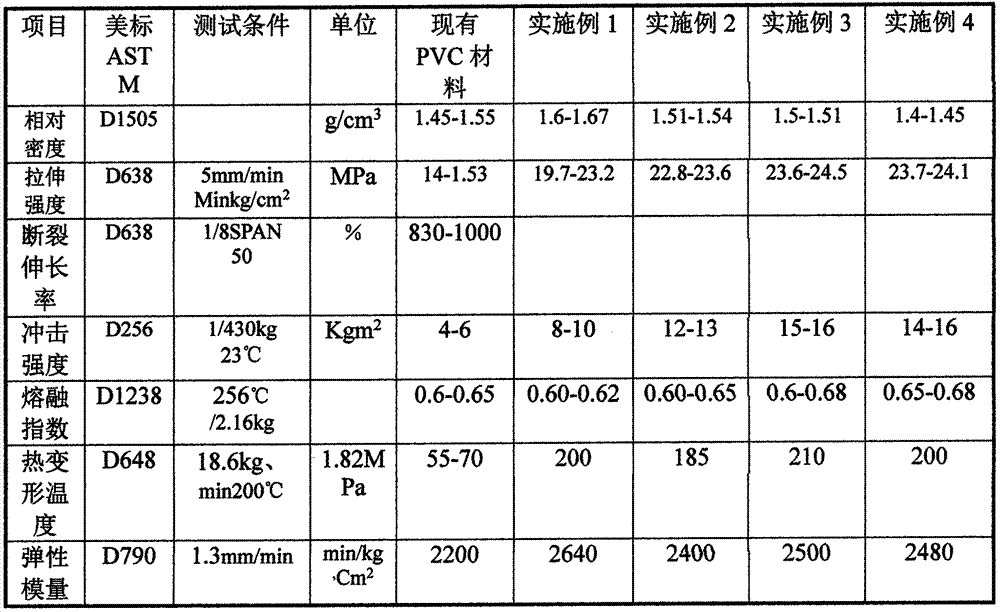

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: present embodiment is a PVC composite modified material, by weight parts by the PVC resin of 60~85 parts, the low-temperature toughening agent of 3.5~10 parts, the impact modifier of 4~9 parts, 2 ~5 parts of processing aids, 0.5~1 parts of surfactants, 2~5 parts of composite stabilizers, 2~5 parts of covering agents, 0.1~0.5 parts of initiators and 0.5~4.5 parts of crosslinking agents Prepared.

[0020] The thermal stability of PVC resin is an important factor that determines its quality, and can directly affect the processing performance and service life. To study PVC is to consider the inherent molecular structure of PVC resin itself, and this structure has unstable factors. Therefore, this paper On the basis of the original modification, the invention increases the viscoelasticity of PVC melt, thereby improving die expansion and melt strength, and improving the molecular structure, crystallinity, direction of microcrystals, and degree of cros...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the PVC resin is a PVC resin with a hardness value of 70. Others are the same as the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the covering agent is rutile titanium dioxide. Others are the same as those in Embodiment 1 or 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap