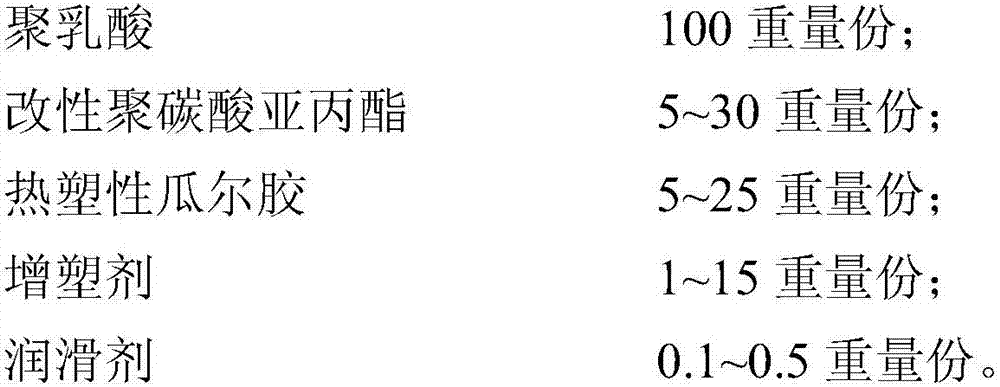

Polylactic acid/modified polypropylene carbonate/thermoplastic guar gum composite material and preparation method thereof

A polypropylene carbonate and composite material technology, which is applied in the field of polylactic acid/modified polypropylene carbonate/thermoplastic guar gum composite material and its preparation, can solve the problems of high cost, poor impact performance, poor processing performance, etc. problem, to achieve the effect of low cost, good processing rheological properties and mechanical properties, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

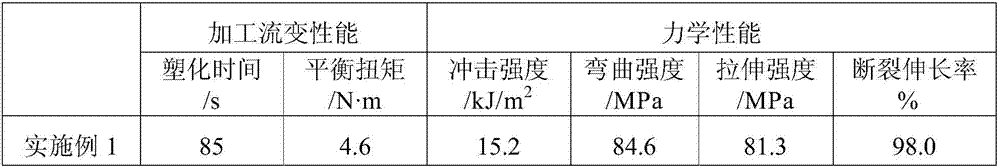

Examples

Embodiment 1

[0022] (1) Preparation of modified nano-zinc oxide: Prepare 600 mL of ethanol / water solution with a volume ratio of 20 / 1, add 20 g of nano-zinc oxide, ultrasonically disperse for 30 min, add 5 mL of KH560, reflux at 80 °C for 180 min, and then cool to room temperature. Washing with ethanol three times, drying in vacuum at 50° C. to obtain modified nanometer zinc oxide.

[0023] (2) Preparation of modified polypropylene carbonate: 300g polypropylene carbonate, 6g modified nano zinc oxide, 3g succinic anhydride and 0.6g epoxy soybean oil were pre-mixed in a high-speed mixer for 15min and then added to the bismuth In a screw extrusion granulator, the modified polypropylene carbonate is obtained by extrusion and granulation after melt blending. The temperature of each section from the feed area to the die of the twin-screw extrusion granulator is: 145°C, 150°C, 155°C, 160°C, 160°C, 158°C, 155°C, the speed of the main engine is 90rpm, and the speed of the feeder is 8.5 rpm.

[00...

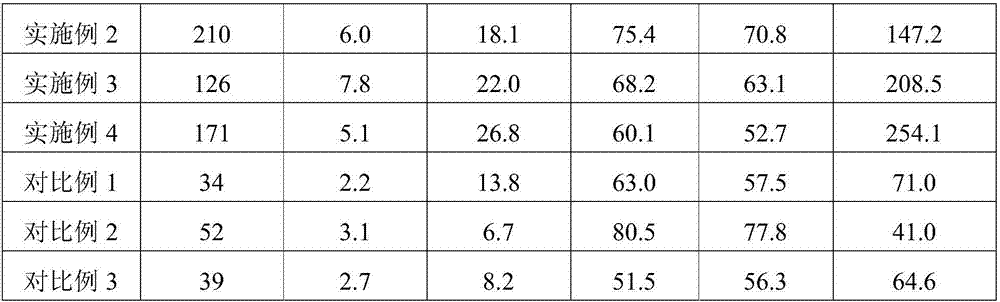

Embodiment 2

[0027] (1) The preparation of modified nano zinc oxide is the same as in Example 1.

[0028] (2) Preparation of modified polypropylene carbonate: 250g polypropylene carbonate, 3.8g modified nano-zinc oxide, 7.5g succinic anhydride and 0.6g epoxy soybean oil were pre-mixed in a high-speed mixer for 15min and then added into a twin-screw extrusion granulator, and then extruded and granulated after melt blending to obtain modified polypropylene carbonate. The temperature of each section from the feed area to the die of the twin-screw extrusion granulator is: 148°C, 152°C, 155°C, 160°C, 162°C, 160°C, 158°C, the speed of the main engine is 105rpm, and the speed of the feeder is 9.8rpm.

[0029] (3) Preparation of thermoplastic guar gum: premix 280g guar gum and 150g glycerin under the action of an electric mixer for 3h, after the glycerin fully swells the guar gum, the premixed material is added to the twin-screw extrusion granulator , after being melted and plasticized, extruded...

Embodiment 3

[0032] (1) The preparation of modified nano zinc oxide is the same as in Example 1.

[0033] (2) Preparation of modified polypropylene carbonate: 400g polypropylene carbonate, 20g modified nano-zinc oxide, 15g maleic anhydride and 3g epoxy butyl stearate were premixed in a high-speed mixer for 15min Adding it into a twin-screw extruding granulator, extruding and granulating after melt blending to obtain modified polypropylene carbonate. The temperatures of each section from the feed area to the die of the twin-screw extrusion granulator are: 150°C, 152°C, 158°C, 162°C, 165°C, 168°C, 165°C, the speed of the main engine is 100rpm, and the speed of the feeder is 9.5 rpm.

[0034] (3) Preparation of thermoplastic guar gum: premix 400g guar gum and 180g glycerin under the action of an electric mixer for 3h, after the glycerin fully swells the guar gum, add the premixed material to the twin-screw extruder granulator , after being melted and plasticized, extruded and granulated to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com