A supermolecule self-assembled fracturing fluid

A supramolecular self-assembly, fracturing fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem that the viscosity and sand-carrying properties of fracturing construction cannot be well satisfied, and it does not have shear recovery. , poor temperature resistance of fracturing fluid, etc., to achieve the effect of improving viscosity and sand-carrying performance, good shear resistance and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

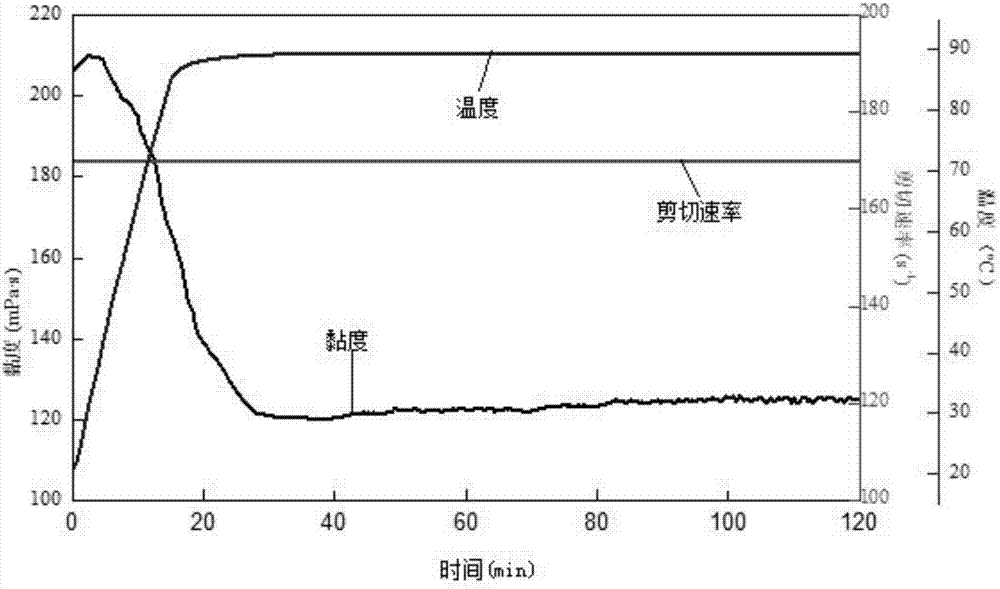

Embodiment 1

[0023] Embodiment 1 provides a supramolecular self-assembly fracturing fluid, each component is composed according to the following mass percentages: supramolecular polymer HMPAM, 0.45%; viscoelastic surfactant SS, 0.1%; ammonium persulfate, 0.1%; The balance is water.

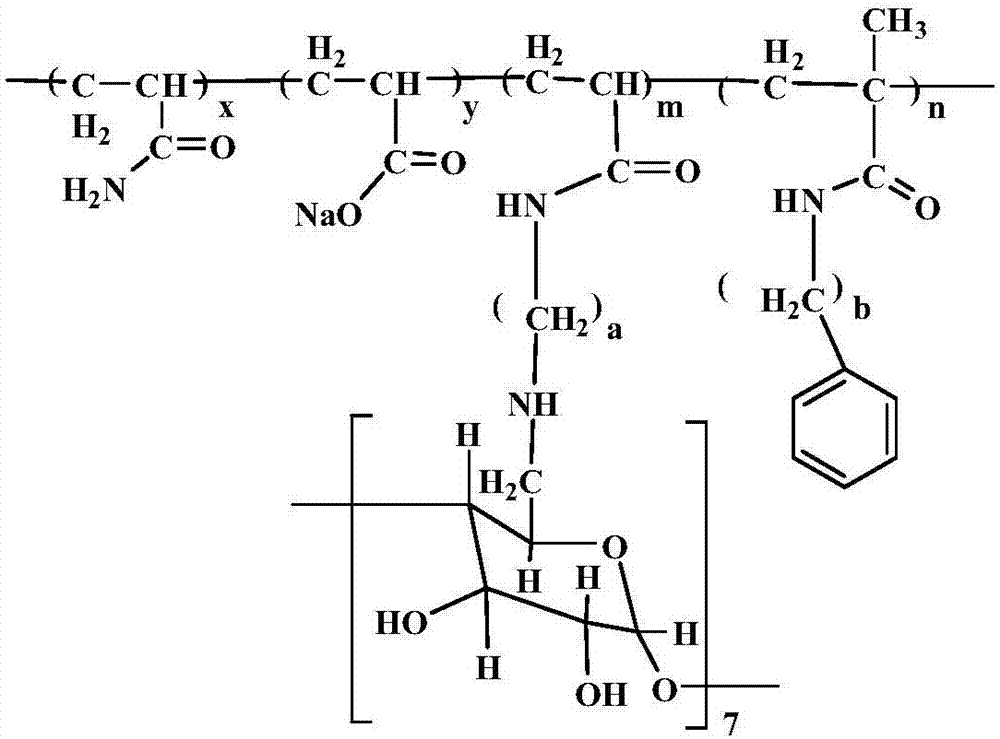

[0024] In this embodiment, the general structural formula of the supramolecular polymer HMPAM is:

[0025]

[0026] In the formula, x is 84.5%, y is 15%, m is 0.3%, n=0.2%;

[0027] a is 6, b is 2;

[0028] The viscosity-average molecular weight of the supramolecular polymer is 5 million.

[0029] In this embodiment, the viscoelastic surfactant SS is composed of the following components by weight percentage: 92.3wt% KCl, 4.6wt% sodium oleate, 3.1wt% polyzwitterionic surfactant DTPAN.

[0030] Specifically, the general structural formula of the above-mentioned polymeric zwitterionic surfactant DTPAN is:

[0031]

[0032] Specifically, the specific functions of each component in the supramolecular self...

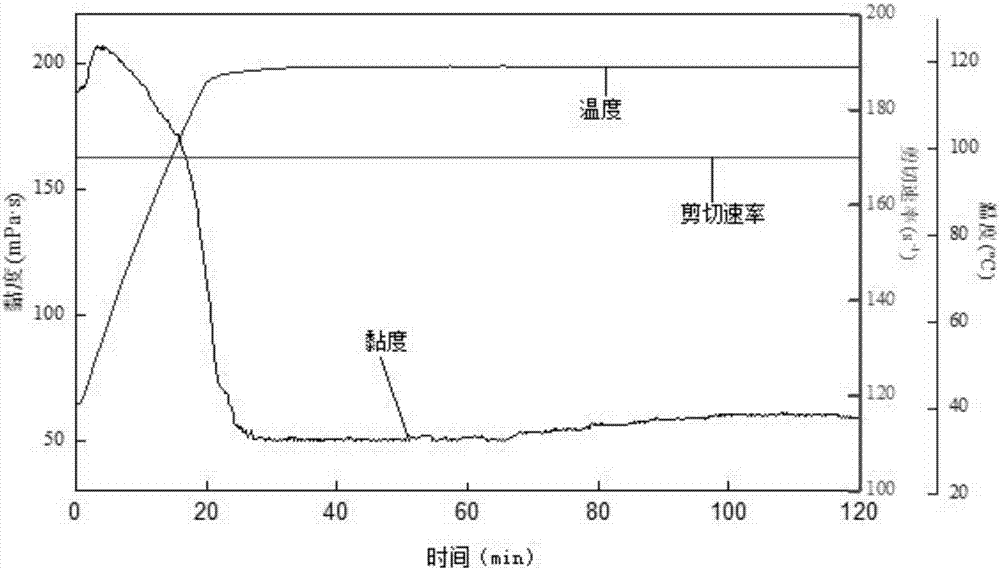

Embodiment 2

[0043] Embodiment 2 provides a supramolecular self-assembly fracturing fluid, each component is composed according to the following mass percentages: supramolecular polymer HMPAM, 0.5%; viscoelastic surfactant SS, 0.1%; ammonium persulfate, 0.1%; The balance is water.

[0044] In this embodiment, the general structural formula of the supramolecular polymer HMPAM is:

[0045]

[0046] In the formula, x is 84.5%, y is 15%, m is 0.3%, n=0.2%;

[0047] a is 6, b is 2;

[0048] The viscosity-average molecular weight of the supramolecular polymer is 5 million.

[0049] Specifically, in this embodiment, the supramolecular polymer HMPAM is used as a thickener for increasing the viscosity of the aqueous solution.

[0050] In this embodiment, the viscoelastic surfactant SS is composed of the following components by weight percentage: 92.3wt% KCl, 4.6wt% sodium oleate, 3.1wt% polyzwitterionic surfactant DTPAN.

[0051] Specifically, the general structural formula of the above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com